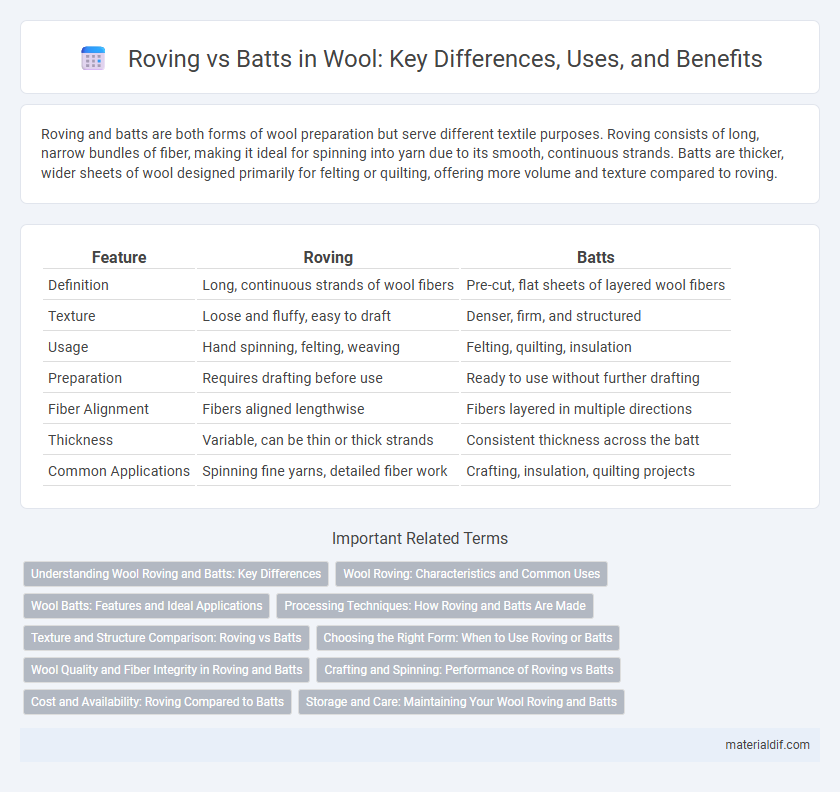

Roving and batts are both forms of wool preparation but serve different textile purposes. Roving consists of long, narrow bundles of fiber, making it ideal for spinning into yarn due to its smooth, continuous strands. Batts are thicker, wider sheets of wool designed primarily for felting or quilting, offering more volume and texture compared to roving.

Table of Comparison

| Feature | Roving | Batts |

|---|---|---|

| Definition | Long, continuous strands of wool fibers | Pre-cut, flat sheets of layered wool fibers |

| Texture | Loose and fluffy, easy to draft | Denser, firm, and structured |

| Usage | Hand spinning, felting, weaving | Felting, quilting, insulation |

| Preparation | Requires drafting before use | Ready to use without further drafting |

| Fiber Alignment | Fibers aligned lengthwise | Fibers layered in multiple directions |

| Thickness | Variable, can be thin or thick strands | Consistent thickness across the batt |

| Common Applications | Spinning fine yarns, detailed fiber work | Crafting, insulation, quilting projects |

Understanding Wool Roving and Batts: Key Differences

Wool roving consists of long, slightly twisted fibers aligned in a rope-like form, ideal for spinning and felting projects requiring strength and smooth texture. Wool batts are thicker, fluffy sheets made by layering and pressing fibers together, providing bulk and loft for insulation or needle felting. Understanding these differences helps crafters select the appropriate wool type for specific textile techniques and project needs.

Wool Roving: Characteristics and Common Uses

Wool roving consists of long, continuous strands of carded wool that maintain fiber alignment, providing excellent strength and smoothness ideal for spinning into yarn. Its dense yet pliable texture enables easy manipulation for felting projects, weaving, and needlework. Common uses of wool roving include hand spinning, wet felting, needle felting, and creating intricate textile art or insulation materials.

Wool Batts: Features and Ideal Applications

Wool batts consist of loosely carded wool fibers that provide exceptional insulation, breathability, and moisture regulation, making them ideal for use in home insulation and soundproofing applications. Their natural fire resistance and durability enhance energy efficiency while maintaining indoor air quality. Wool batts are preferred for eco-friendly building projects and crafts requiring soft, flexible wool materials.

Processing Techniques: How Roving and Batts Are Made

Roving is produced through a drafting process where wool fibers are aligned and slightly twisted into long, continuous strands, optimizing fiber strength and uniformity for spinning. Batts are created by layering and compressing carded wool fibers using a needle felting or light adhesive treatment, resulting in thick, cohesive sheets ideal for felting or insulation. The distinct processing techniques of drafting for roving and layering combined with needle felting for batts directly influence their texture, durability, and end-use applications in textile and craft projects.

Texture and Structure Comparison: Roving vs Batts

Roving wool features a thick, continuous strand with a smooth, dense texture ideal for spinning and felting, while batts are airy, layered sheets with a fluffy, lofty structure designed for easier manipulation in needle felting and quilting. The compact nature of roving provides greater strength and uniformity, whereas batts offer more versatility with varied fiber blends and thicknesses for creative projects. Choosing between roving and batts depends on the desired texture and structural properties suitable for specific wool crafting techniques.

Choosing the Right Form: When to Use Roving or Batts

Roving offers thicker, continuous strands ideal for hand spinning and wet felting projects requiring more control and structure, while batts provide a fluffy, carded sheet perfect for needle felting, blending fibers, and creating lightweight fabrics. Choosing roving enhances durability and strength in woven or knitted items, whereas batts deliver versatility for artistic expressions and multi-fiber combinations. Understanding project needs--such as fiber alignment, texture, and technique--guides selecting the optimal wool form for enhanced crafting outcomes.

Wool Quality and Fiber Integrity in Roving and Batts

Wool roving maintains higher fiber integrity due to minimal processing, preserving the natural crimp and strength of the fibers, which enhances insulation and durability. Batts undergo more extensive carding and sometimes blending, which can slightly reduce fiber quality but provide uniform thickness and ease of use for felting or spinning. Choosing between roving and batts depends on the intended application, with roving favored for superior fiber alignment and quality, while batts prioritize versatility and convenience.

Crafting and Spinning: Performance of Roving vs Batts

Roving offers a more consistent thickness and smoother texture, making it ideal for spinning fine, even yarns with minimal drafting effort. Batts, with their thicker and sometimes uneven layers, excel in crafting projects like felting and needlework that require loft and texture rather than uniformity. Wool roving ensures better control and efficiency in spinning, while batts provide versatility and visual interest in various crafting applications.

Cost and Availability: Roving Compared to Batts

Wool roving generally costs more than batts due to the additional processing required to create long, continuous fibers, impacting its availability across markets. Batts are more widely available and often preferred for bulk purchases because they are easier and faster to produce in larger quantities. The higher price and limited supply of roving make it ideal for specialized textile projects where fiber alignment and smoothness are critical.

Storage and Care: Maintaining Your Wool Roving and Batts

Proper storage of wool roving and batts involves keeping them in a cool, dry place away from direct sunlight to prevent discoloration and fiber damage. Using breathable cotton bags or acid-free tissue paper helps protect these wool forms from moisture, pests, and compression, preserving their loft and texture. Regularly inspecting stored wool and gently fluffing batts maintains fiber integrity and ensures readiness for future felting or spinning projects.

Roving vs Batts Infographic

materialdif.com

materialdif.com