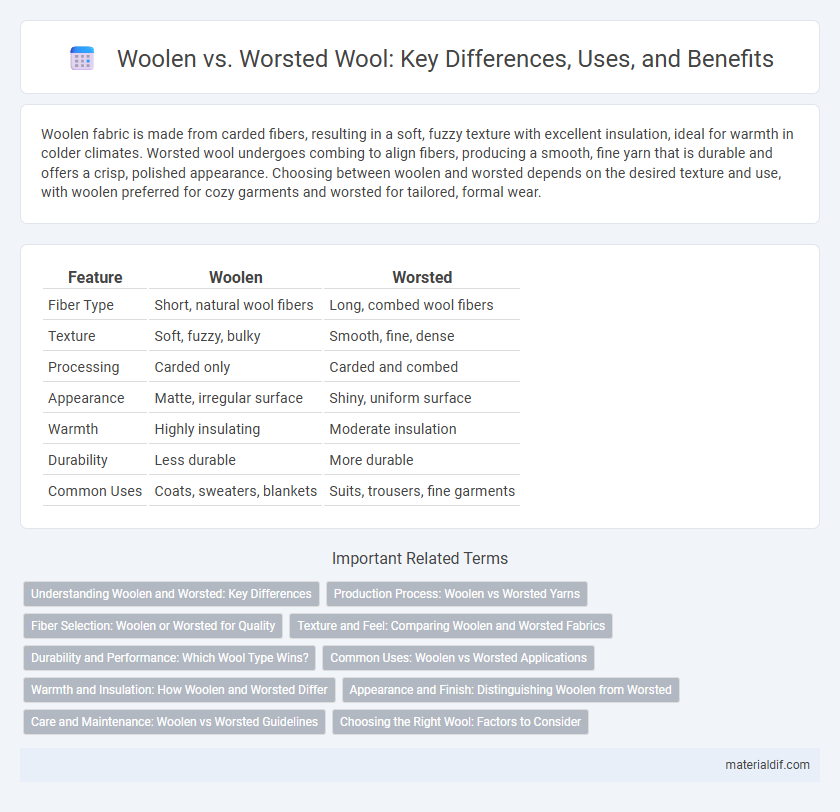

Woolen fabric is made from carded fibers, resulting in a soft, fuzzy texture with excellent insulation, ideal for warmth in colder climates. Worsted wool undergoes combing to align fibers, producing a smooth, fine yarn that is durable and offers a crisp, polished appearance. Choosing between woolen and worsted depends on the desired texture and use, with woolen preferred for cozy garments and worsted for tailored, formal wear.

Table of Comparison

| Feature | Woolen | Worsted |

|---|---|---|

| Fiber Type | Short, natural wool fibers | Long, combed wool fibers |

| Texture | Soft, fuzzy, bulky | Smooth, fine, dense |

| Processing | Carded only | Carded and combed |

| Appearance | Matte, irregular surface | Shiny, uniform surface |

| Warmth | Highly insulating | Moderate insulation |

| Durability | Less durable | More durable |

| Common Uses | Coats, sweaters, blankets | Suits, trousers, fine garments |

Understanding Woolen and Worsted: Key Differences

Woolen fabric is made from carded fibers that are shorter and randomly arranged, resulting in a soft, fluffy texture ideal for warmth and insulation. Worsted wool uses long, combed fibers aligned parallel, producing a smooth, fine yarn that enhances durability and creates a sleek appearance. Understanding these differences is crucial for selecting wool based on desired texture, warmth, and garment structure.

Production Process: Woolen vs Worsted Yarns

Woolen yarns are produced by carding raw wool fibers, which align them loosely and result in a thick, soft, and fuzzy texture that traps air for warmth and insulation. Worsted yarns undergo an extra step called combing, which removes shorter fibers and aligns the remaining long fibers parallel, creating a smooth, strong, and fine yarn suited for high-quality fabrics. The difference in production processes significantly impacts the texture, strength, and end-use of woolen versus worsted textiles.

Fiber Selection: Woolen or Worsted for Quality

Fiber selection significantly influences the quality of woolen and worsted fabrics, with woolen using shorter, finer fibers that contribute to its soft, insulating texture ideal for warmth and bulk. Worsted fabric employs long, smooth fibers that are combed and aligned, resulting in a dense, durable textile with a crisp finish suitable for high-quality suits and formal wear. Choosing woolen or worsted depends on the desired fabric characteristics, balancing softness and insulation against strength and smoothness.

Texture and Feel: Comparing Woolen and Worsted Fabrics

Woolen fabrics have a soft, fuzzy texture due to the shorter, carded fibers that are loosely spun, creating a warm and insulating feel ideal for cozy garments. Worsted fabrics feature long, combed fibers tightly spun to produce a smooth, fine texture with a polished appearance, offering a crisp feel often used in suiting and formal wear. The distinct processing methods of woolen and worsted affect their durability, warmth, and tactile experience, making each suitable for different clothing purposes.

Durability and Performance: Which Wool Type Wins?

Worsted wool offers superior durability and performance due to its tightly spun fibers, resulting in a smooth, strong fabric ideal for suits and outerwear. Woolen wool, while softer and warmer, features loosely spun fibers that provide better insulation but less resistance to wear and tear. For long-lasting garments that maintain shape and resist pilling, worsted wool is the optimal choice.

Common Uses: Woolen vs Worsted Applications

Woolen fabrics, characterized by their soft, fuzzy texture and excellent insulation, are commonly used in cozy garments such as sweaters, blankets, and winter coats, providing warmth and comfort. Worsted wool, known for its smooth, fine yarns and durability, is often chosen for formal wear including suits, trousers, and high-quality uniforms due to its sleek appearance and wrinkle resistance. The distinct spinning processes of woolen and worsted fibers dictate their applications, aligning woolen with casual, insulating apparel and worsted with structured, professional clothing.

Warmth and Insulation: How Woolen and Worsted Differ

Woolen fabrics provide superior warmth and insulation due to their loosely spun fibers that trap more air, creating a natural barrier against cold. Worsted wool, with tightly spun, smooth fibers, offers less insulation but delivers a sleek, durable finish ideal for formal wear. The airy structure of woolen textiles makes them better suited for cold weather garments, while worsted fabric excels in breathability and strength.

Appearance and Finish: Distinguishing Woolen from Worsted

Woolen fabrics exhibit a soft, fuzzy surface with a matte finish due to the shorter, carded fibers that create a loftier texture, ideal for warmth and insulation. Worsted fabrics showcase a smooth, firm, and tightly woven finish with long combed fibers aligned parallel, resulting in a sleek, polished appearance and greater durability. The distinct finishing processes of woolen and worsted significantly affect their look, feel, and performance in textile applications.

Care and Maintenance: Woolen vs Worsted Guidelines

Woolen fabrics, characterized by their loosely spun fibers, require gentle care including hand washing with cold water and mild detergent to maintain loft and softness, while avoiding excessive agitation to prevent felting. Worsted wool, with tightly spun and combed fibers, is more durable and often suitable for dry cleaning or gentle machine washing on a wool cycle, maintaining its smooth finish and shape. Proper storage in a cool, dry place with moth repellents is crucial for both woolen and worsted garments to preserve fiber integrity and longevity.

Choosing the Right Wool: Factors to Consider

Woolen fabrics are characterized by their soft, warm, and fuzzy texture, making them ideal for insulation and casual wear, while worsted wool offers a smoother, finer finish suitable for formal garments due to its tightly spun fibers. When choosing between woolen and worsted, consider factors such as insulation needs, garment durability, and fabric drape; woolen excels in warmth and bulk, whereas worsted provides strength and a polished appearance. The specific application, desired comfort level, and climate conditions play critical roles in selecting the right type of wool for your textile projects or wardrobe.

Woolen vs Worsted Infographic

materialdif.com

materialdif.com