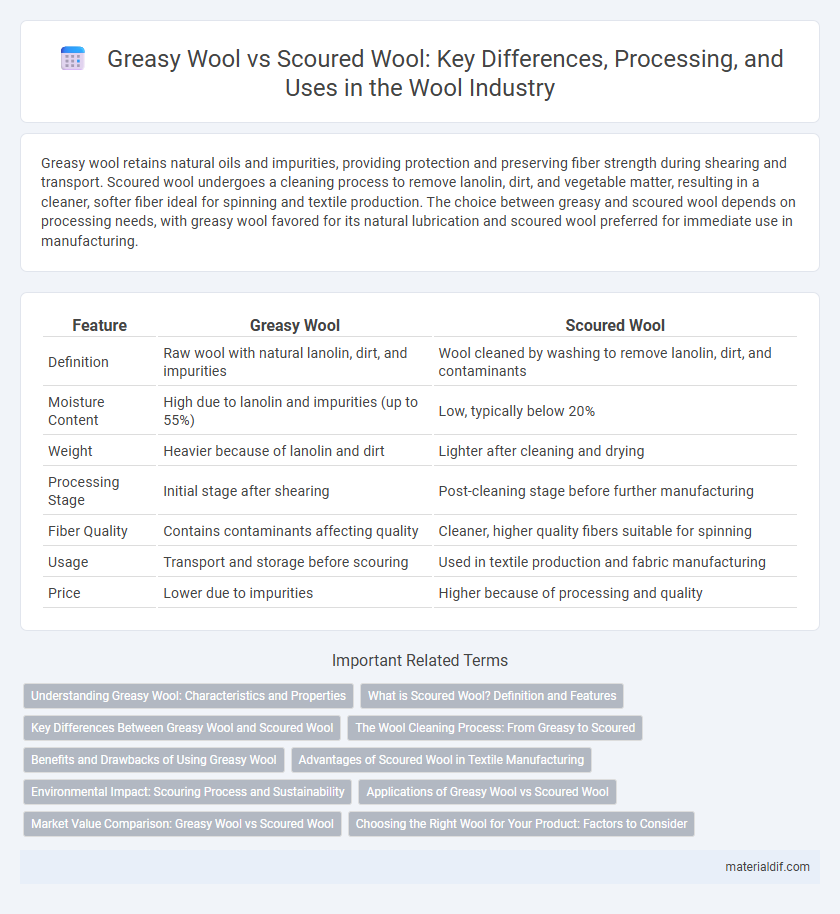

Greasy wool retains natural oils and impurities, providing protection and preserving fiber strength during shearing and transport. Scoured wool undergoes a cleaning process to remove lanolin, dirt, and vegetable matter, resulting in a cleaner, softer fiber ideal for spinning and textile production. The choice between greasy and scoured wool depends on processing needs, with greasy wool favored for its natural lubrication and scoured wool preferred for immediate use in manufacturing.

Table of Comparison

| Feature | Greasy Wool | Scoured Wool |

|---|---|---|

| Definition | Raw wool with natural lanolin, dirt, and impurities | Wool cleaned by washing to remove lanolin, dirt, and contaminants |

| Moisture Content | High due to lanolin and impurities (up to 55%) | Low, typically below 20% |

| Weight | Heavier because of lanolin and dirt | Lighter after cleaning and drying |

| Processing Stage | Initial stage after shearing | Post-cleaning stage before further manufacturing |

| Fiber Quality | Contains contaminants affecting quality | Cleaner, higher quality fibers suitable for spinning |

| Usage | Transport and storage before scouring | Used in textile production and fabric manufacturing |

| Price | Lower due to impurities | Higher because of processing and quality |

Understanding Greasy Wool: Characteristics and Properties

Greasy wool, also known as raw wool, contains lanolin, dirt, and natural oils, giving it a waxy texture and a higher moisture content compared to scoured wool. This unprocessed state preserves the wool's natural protective qualities, such as water resistance and elasticity, which are essential for various textile applications. Understanding the characteristics of greasy wool is crucial for manufacturers to determine the appropriate cleaning and processing methods before transforming it into high-quality scoured wool.

What is Scoured Wool? Definition and Features

Scoured wool refers to raw wool that has undergone a thorough cleaning process to remove impurities such as grease, dirt, sweat residue, and vegetable matter, resulting in a cleaner and more manageable fiber. This wool is free from lanolin and contaminants, making it suitable for textile manufacturing and further processing into fine yarns and fabrics. The scouring process enhances fiber quality, improves dye uptake, and increases wool's commercial value by ensuring consistency and hygiene.

Key Differences Between Greasy Wool and Scoured Wool

Greasy wool contains natural impurities such as lanolin, dirt, and vegetable matter, making it raw and unprocessed fiber directly from the sheep. Scoured wool undergoes a thorough cleaning process that removes these contaminants, resulting in soft, clean fibers ready for spinning or textile production. The key difference lies in their preparation: greasy wool requires further processing, while scoured wool is prepared for immediate use in manufacturing.

The Wool Cleaning Process: From Greasy to Scoured

The wool cleaning process transforms greasy wool, which contains natural oils like lanolin, dirt, and vegetable matter, into scoured wool that is soft, clean, and ready for spinning or further processing. Scouring involves washing greasy wool in hot water with detergents to remove impurities and lanolin while preserving fiber quality and length. This crucial step enhances wool's fiber strength, dye uptake, and overall textile performance by producing a clean, contaminant-free material.

Benefits and Drawbacks of Using Greasy Wool

Greasy wool retains natural lanolin, which provides excellent water resistance and maintains fiber strength, making it ideal for spinning and handcrafting. It requires extensive cleaning to remove dirt, lanolin, and impurities, resulting in higher processing costs and potential environmental concerns. The unprocessed state preserves the wool's natural oils, benefiting applications where moisture regulation and durability are important.

Advantages of Scoured Wool in Textile Manufacturing

Scoured wool offers significant advantages in textile manufacturing by removing impurities such as grease, dirt, and lanolin, resulting in a cleaner, more consistent fiber ideal for spinning. This purification process enhances fiber quality, improves dye uptake, and increases fabric uniformity, leading to superior textile products. Manufacturers benefit from reduced processing time and lower machinery wear, making scoured wool a preferred raw material in high-quality fabric production.

Environmental Impact: Scouring Process and Sustainability

Greasy wool contains natural lanolin and impurities, requiring the scouring process to remove contaminants, which involves significant water and chemical use impacting the environment. Scoured wool, though cleaner and ready for processing, generates wastewater containing lanolin and other pollutants that must be treated to prevent ecological harm. Sustainable practices in wool scouring prioritize water recycling, bio-based detergents, and waste recovery systems to minimize the environmental footprint of wool production.

Applications of Greasy Wool vs Scoured Wool

Greasy wool retains lanolin and natural oils, making it ideal for products requiring moisture resistance and durability, such as insulation, felting, and carpet manufacturing. Scoured wool, which is cleaned of impurities, suits applications in fine textiles, garments, and high-quality yarn production where softness and purity are essential. The choice between greasy and scoured wool impacts processing methods and end-use performance in industries like apparel, home furnishings, and industrial fabrics.

Market Value Comparison: Greasy Wool vs Scoured Wool

Greasy wool retains lanolin and impurities, reducing its immediate market value compared to scoured wool, which has been cleaned and processed for higher quality and demand. Scoured wool commands a premium price due to its improved appearance, softness, and suitability for textile manufacturing. Market prices for greasy wool fluctuate based on lanolin content and contamination, while scoured wool prices are steadier, reflecting consistent quality and readiness for production.

Choosing the Right Wool for Your Product: Factors to Consider

Greasy wool contains natural lanolin, dirt, and impurities, making it heavier and requiring thorough cleaning, while scoured wool is washed and ready for immediate use, offering consistent fiber quality. Choosing the right wool depends on product requirements such as softness, durability, and moisture resistance, with greasy wool suited for products needing natural lanolin benefits and scoured wool ideal for fine textiles and sensitive skin applications. Consider factors like fiber cleanliness, processing costs, and end-use functionality to optimize product performance and cost-efficiency.

Greasy wool vs Scoured wool Infographic

materialdif.com

materialdif.com