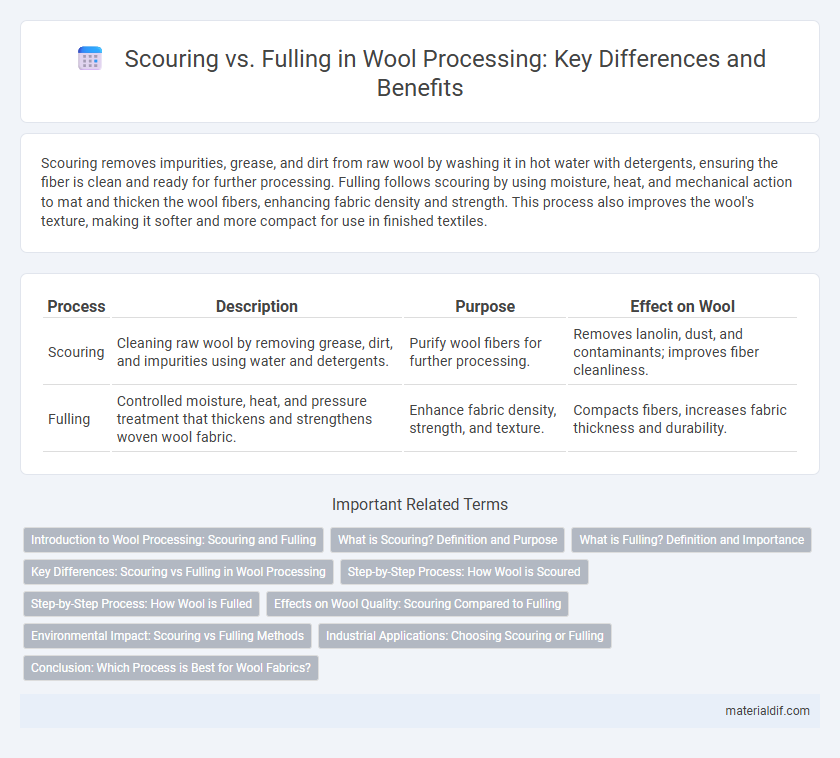

Scouring removes impurities, grease, and dirt from raw wool by washing it in hot water with detergents, ensuring the fiber is clean and ready for further processing. Fulling follows scouring by using moisture, heat, and mechanical action to mat and thicken the wool fibers, enhancing fabric density and strength. This process also improves the wool's texture, making it softer and more compact for use in finished textiles.

Table of Comparison

| Process | Description | Purpose | Effect on Wool |

|---|---|---|---|

| Scouring | Cleaning raw wool by removing grease, dirt, and impurities using water and detergents. | Purify wool fibers for further processing. | Removes lanolin, dust, and contaminants; improves fiber cleanliness. |

| Fulling | Controlled moisture, heat, and pressure treatment that thickens and strengthens woven wool fabric. | Enhance fabric density, strength, and texture. | Compacts fibers, increases fabric thickness and durability. |

Introduction to Wool Processing: Scouring and Fulling

Scouring removes natural oils, dirt, and impurities from raw wool, ensuring cleanliness and preparing fibers for further processing. Fulling follows, compressing and matting the wool fibers to increase density, strength, and fabric cohesion. These essential steps transform raw fleece into durable, high-quality wool suitable for textile production.

What is Scouring? Definition and Purpose

Scouring is the crucial process of cleaning raw wool by removing grease, dirt, sweat salts, and vegetable matter to prepare it for further textile manufacturing. This step typically involves washing the wool in a series of baths containing water and detergents or alkalis to ensure thorough purification. Effective scouring enhances wool's quality by improving its fiber cleanliness, softness, and readiness for dyeing or spinning.

What is Fulling? Definition and Importance

Fulling is a controlled process in wool manufacturing that involves cleansing and thickening the fabric by matting fibers together through moisture, heat, and pressure. This treatment enhances wool's durability, density, and water resistance, making garments warmer and more resilient. Unlike scouring, which removes impurities from raw wool, fulling structurally refines the fabric to improve texture and strength.

Key Differences: Scouring vs Fulling in Wool Processing

Scouring in wool processing involves thoroughly washing raw wool to remove impurities such as grease, dirt, and vegetable matter, enhancing fiber cleanliness and preparing it for further treatment. Fulling, also known as milling, is a controlled process where wool fibers are agitated in water, causing them to interlock and thicken the fabric, thereby increasing density and improving texture. While scouring focuses on purification and preparation, fulling primarily enhances the fabric's strength, compactness, and hand feel.

Step-by-Step Process: How Wool is Scoured

Wool scouring involves a step-by-step cleaning process to remove grease, dirt, and impurities from raw fleece using water, detergent, and alkali solutions in sequential baths. The fleece undergoes washing, rinsing, and drying stages, ensuring the removal of lanolin and contaminants while preserving fiber quality. This preparation contrasts with fulling, which is a finishing process that thickens and strengthens woven wool fabrics through moisture, heat, and pressure.

Step-by-Step Process: How Wool is Fulled

Fulling wool involves a controlled process of cleansing and thickening fibers through moisture, heat, and mechanical agitation, distinct from scouring which primarily removes grease and dirt. Initially, the wool is soaked in warm water mixed with detergents or natural soaps to loosen impurities and mat the fibers together. The fibers are then subjected to repeated kneading or pounding, often in specialized fulling mills, causing the wool to shrink, thicken, and develop a dense, compact texture essential for durable woolen fabric production.

Effects on Wool Quality: Scouring Compared to Fulling

Scouring effectively removes grease, dirt, and impurities from raw wool, enhancing its cleanliness and preparing fibers for further processing without significantly altering fiber structure. Fulling, a controlled felting process, compacts wool fibers, increasing fabric density, strength, and water resistance while simultaneously reducing softness and flexibility. The choice between scouring and fulling directly impacts wool quality; scouring preserves fiber length and softness, whereas fulling modifies texture and durability for specific end-use applications.

Environmental Impact: Scouring vs Fulling Methods

Scouring wool involves the use of large quantities of water and detergents to remove grease, dirt, and impurities, generating wastewater that requires careful treatment to prevent environmental contamination. Fulling, a mechanical process that cleans and thickens wool by matting fibers, generally consumes less water and produces minimal effluent, making it a more environmentally friendly choice. Selecting fulling over scouring reduces water pollution and lowers energy consumption, supporting sustainable wool processing practices.

Industrial Applications: Choosing Scouring or Fulling

Scouring and fulling serve distinct industrial purposes in wool processing, with scouring primarily removing impurities such as grease, dirt, and lanolin, enhancing fiber cleanliness for textile production. Fulling, conversely, involves controlled moisture, heat, and mechanical action to compact and strengthen the wool fabric, improving its texture and durability. Selecting between scouring and fulling depends on the desired end-product quality, where scouring is essential for preparing raw wool, while fulling is crucial for finishing woven or knitted wool textiles.

Conclusion: Which Process is Best for Wool Fabrics?

Scouring effectively removes grease, dirt, and impurities from raw wool, ensuring cleanliness and preparing the fibers for further processing. Fulling enhances wool's texture by matting and thickening the fabric, improving durability and insulation properties. Choosing between scouring and fulling depends on the desired end-use; scouring is essential for initial cleaning, while fulling is best for producing dense, warm wool fabrics.

Scouring vs Fulling Infographic

materialdif.com

materialdif.com