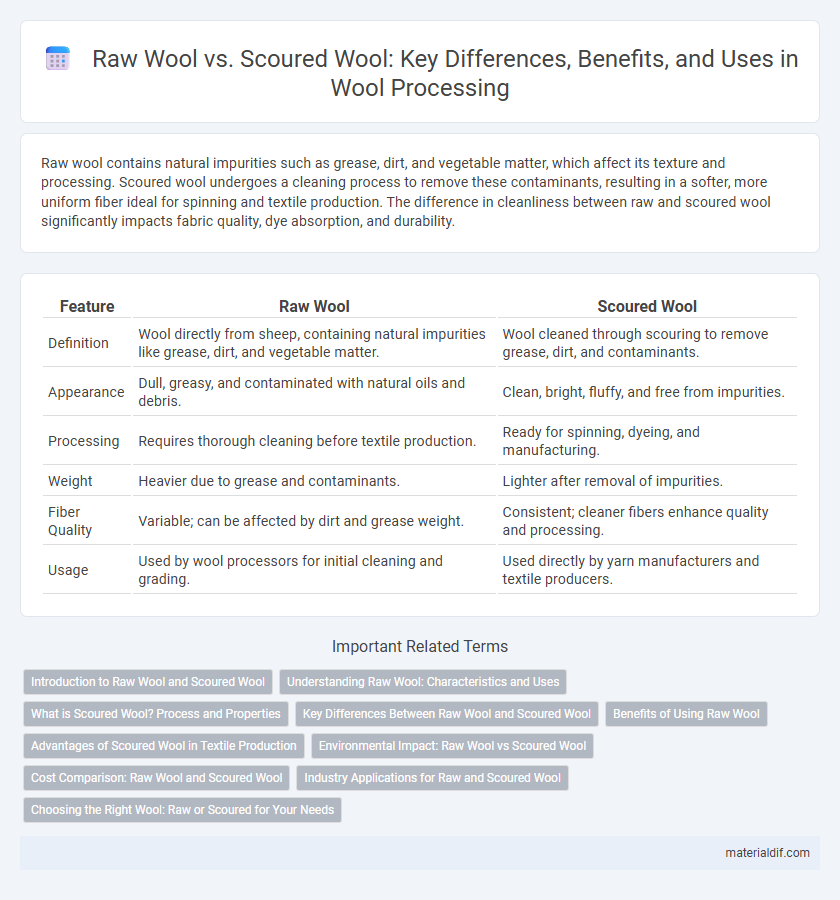

Raw wool contains natural impurities such as grease, dirt, and vegetable matter, which affect its texture and processing. Scoured wool undergoes a cleaning process to remove these contaminants, resulting in a softer, more uniform fiber ideal for spinning and textile production. The difference in cleanliness between raw and scoured wool significantly impacts fabric quality, dye absorption, and durability.

Table of Comparison

| Feature | Raw Wool | Scoured Wool |

|---|---|---|

| Definition | Wool directly from sheep, containing natural impurities like grease, dirt, and vegetable matter. | Wool cleaned through scouring to remove grease, dirt, and contaminants. |

| Appearance | Dull, greasy, and contaminated with natural oils and debris. | Clean, bright, fluffy, and free from impurities. |

| Processing | Requires thorough cleaning before textile production. | Ready for spinning, dyeing, and manufacturing. |

| Weight | Heavier due to grease and contaminants. | Lighter after removal of impurities. |

| Fiber Quality | Variable; can be affected by dirt and grease weight. | Consistent; cleaner fibers enhance quality and processing. |

| Usage | Used by wool processors for initial cleaning and grading. | Used directly by yarn manufacturers and textile producers. |

Introduction to Raw Wool and Scoured Wool

Raw wool is the fleece shorn directly from sheep, containing natural impurities such as grease, dirt, lanolin, and vegetable matter. Scoured wool undergoes a thorough cleaning process using warm water and detergents to remove these contaminants, resulting in a purer fiber ideal for textile manufacturing. This distinction impacts wool quality, processing efficiency, and final product performance in the apparel and upholstery industries.

Understanding Raw Wool: Characteristics and Uses

Raw wool retains natural lanolin, dirt, and vegetable matter, giving it a greasy texture and earthy aroma that preserves its original qualities. It is valued for its protective properties and is primarily used in initial processing stages such as carding and spinning, where impurities are removed. Understanding raw wool's composition is essential for optimizing scouring methods that prepare it for high-quality textile production.

What is Scoured Wool? Process and Properties

Scoured wool is raw wool that has undergone a thorough cleaning process to remove grease, dirt, and impurities such as lanolin and vegetable matter. The scouring process typically involves washing the raw fleece in a series of alkaline solutions and detergents, followed by rinsing and drying to produce a clean, soft fiber suitable for textile manufacturing. This treatment enhances wool's properties by improving fiber cleanliness, softness, and dye absorption, making scoured wool essential for high-quality fabric production.

Key Differences Between Raw Wool and Scoured Wool

Raw wool contains natural impurities such as grease, lanolin, dirt, and vegetable matter, which scoured wool undergoes a thorough washing process to remove. Scoured wool exhibits enhanced softness, cleanliness, and improved dye absorption, making it more suitable for textile manufacturing. The key difference lies in the purity and preparation level, as raw wool needs scouring to meet industry quality standards for further processing.

Benefits of Using Raw Wool

Raw wool retains natural lanolin, providing superior moisture resistance and natural antibacterial properties essential for durable textile applications. The fiber's natural oils act as a protective barrier, reducing the need for chemical treatments and enhancing eco-friendly production processes. Utilizing raw wool ensures better insulation and a softer texture, which improves comfort and performance in garments and upholstery.

Advantages of Scoured Wool in Textile Production

Scoured wool offers significant advantages in textile production due to its purity, as the cleaning process removes natural oils, dirt, and impurities, resulting in a softer and more uniform fiber. This enhances dye absorption and fabric quality, providing better color consistency and improved texture in finished textiles. Furthermore, scoured wool reduces processing defects, leading to increased efficiency and higher-value end products in the wool industry.

Environmental Impact: Raw Wool vs Scoured Wool

Raw wool retains natural lanolin and impurities, requiring less energy and water for initial processing compared to scoured wool. Scoured wool involves intensive washing with detergents and chemicals, leading to higher water consumption and wastewater generation that impacts aquatic ecosystems. Choosing raw wool reduces environmental footprint by minimizing chemical use and conserving water resources during production.

Cost Comparison: Raw Wool and Scoured Wool

Raw wool is generally less expensive due to minimal processing, but it contains impurities like grease, dirt, and vegetable matter, affecting the overall quality and usability. Scoured wool undergoes thorough cleaning to remove these contaminants, increasing production costs and resulting in a higher market price. The cost difference reflects the added value of scouring, which improves fiber cleanliness, weight, and performance for textile manufacturing.

Industry Applications for Raw and Scoured Wool

Raw wool, containing natural oils, dirt, and vegetable matter, is primarily used in industries where initial processing occurs, such as in carpet manufacturing and insulation materials, due to its durability and cost-effectiveness. Scoured wool undergoes thorough washing to remove impurities, making it ideal for textile applications including apparel, upholstery, and high-quality knitwear that require softness and enhanced dye absorption. The choice between raw and scoured wool depends heavily on the end-use requirements for cleanliness, texture, and performance in industrial applications.

Choosing the Right Wool: Raw or Scoured for Your Needs

Selecting the right wool depends on your project requirements, as raw wool contains natural lanolin, dirt, and vegetable matter, making it ideal for crafts needing texture and natural oils. Scoured wool undergoes thorough cleaning, removing impurities to provide a softer, cleaner, and more consistent fiber suitable for spinning, felting, and textile production. Consider the desired finish, cleanliness, and fiber preparation when choosing raw versus scoured wool to achieve optimal results.

Raw Wool vs Scoured Wool Infographic

materialdif.com

materialdif.com