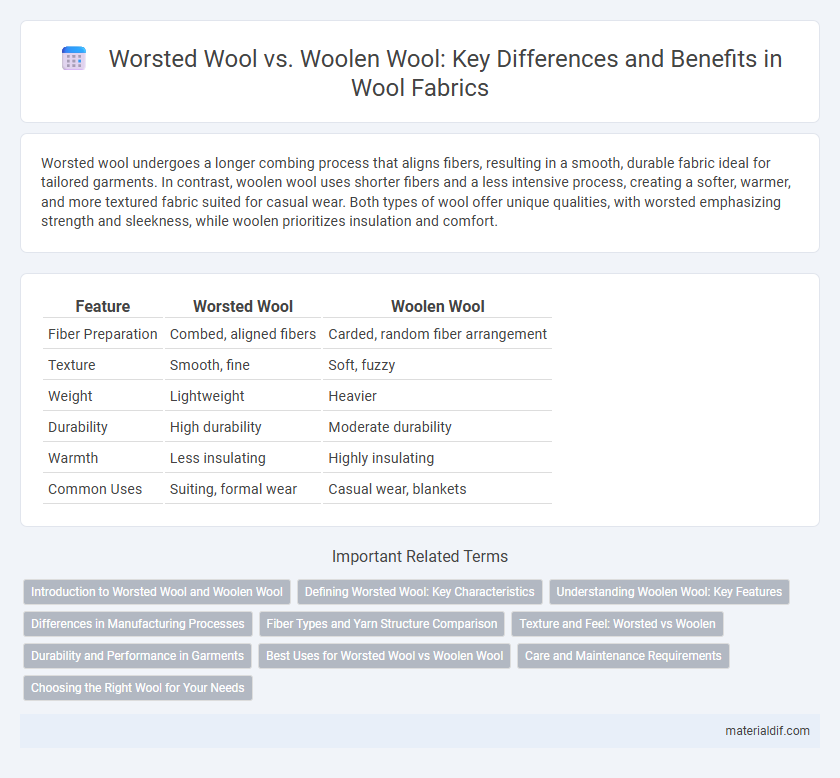

Worsted wool undergoes a longer combing process that aligns fibers, resulting in a smooth, durable fabric ideal for tailored garments. In contrast, woolen wool uses shorter fibers and a less intensive process, creating a softer, warmer, and more textured fabric suited for casual wear. Both types of wool offer unique qualities, with worsted emphasizing strength and sleekness, while woolen prioritizes insulation and comfort.

Table of Comparison

| Feature | Worsted Wool | Woolen Wool |

|---|---|---|

| Fiber Preparation | Combed, aligned fibers | Carded, random fiber arrangement |

| Texture | Smooth, fine | Soft, fuzzy |

| Weight | Lightweight | Heavier |

| Durability | High durability | Moderate durability |

| Warmth | Less insulating | Highly insulating |

| Common Uses | Suiting, formal wear | Casual wear, blankets |

Introduction to Worsted Wool and Woolen Wool

Worsted wool is made from long-staple fibers that are combed to lie parallel, producing a smooth, strong, and fine-textured fabric ideal for tailored garments like suits. Woolen wool, in contrast, uses shorter fibers that are carded rather than combed, creating a soft, warm, and bulky fabric often used in cozy sweaters and blankets. The differences in fiber length and processing techniques give worsted wool a sleek finish, while woolen wool retains more air for insulation and softness.

Defining Worsted Wool: Key Characteristics

Worsted wool is defined by its smooth, fine texture achieved through a unique spinning process that aligns wool fibers parallel, creating a dense, durable fabric ideal for tailored garments. This type of wool undergoes combing to remove shorter fibers, resulting in a sleek surface and enhanced strength compared to woolen wool. Its high tensile strength and resistance to wrinkles make worsted wool a preferred choice for suits and formal wear.

Understanding Woolen Wool: Key Features

Woolen wool is characterized by its loosely spun fibers that create a soft, warm, and fuzzy texture ideal for insulation in colder climates. This type of wool undergoes carding rather than combing, which retains shorter fibers and produces a bulkier, air-trapping fabric with a matte finish. Woolen wool is commonly used in products like sweaters, blankets, and heavy outerwear, emphasizing comfort and warmth over a smooth, sleek appearance.

Differences in Manufacturing Processes

Worsted wool undergoes a combing process that aligns fibers parallel to produce a smooth, strong yarn, while woolen wool is carded to create a softer, bulkier yarn with a more textured surface. The worsted method removes shorter fibers, resulting in a finer, denser fabric, whereas woolen processing retains more natural fibers, enhancing warmth and insulation. These manufacturing differences impact the final fabric's appearance, durability, and suitability for tailored versus casual garments.

Fiber Types and Yarn Structure Comparison

Worsted wool is made from long-staple fibers that are combed to align them parallel, creating a smooth, dense yarn ideal for fine suits and tailored garments. Woolen wool uses shorter fibers that are carded in a more random orientation, resulting in a loftier, softer, and warmer yarn suitable for sweaters and blankets. The yarn structure of worsted wool is tightly twisted, providing strength and durability, while woolen wool has a looser twist, enhancing insulation and elasticity.

Texture and Feel: Worsted vs Woolen

Worsted wool features a smooth, tightly spun texture that results in a firm, crisp feel, ideal for fine suits and formal wear. Woolen wool has a softer, fuzzier texture due to shorter, more loosely spun fibers, offering warmth and a cozy, slightly bulky feel often used in sweaters and casual garments. The distinct spinning processes create these contrasting textures, influencing the drape and appearance of the final fabric.

Durability and Performance in Garments

Worsted wool, known for its tightly spun fibers, offers superior durability and a smooth finish ideal for tailored garments subjected to frequent wear and tear. Woolen wool features a looser fiber structure, resulting in a softer, bulkier fabric that excels in insulation but may wear down faster under heavy use. Performance-wise, worsted wool provides better resistance to pilling and retains shape longer, making it the preferred choice for durable, high-performance clothing.

Best Uses for Worsted Wool vs Woolen Wool

Worsted wool, characterized by its smooth, fine fibers, is best suited for tailored garments such as suits, trousers, and formal wear due to its durability and crisp finish. Woolen wool, made from shorter, fuzzier fibers, excels in insulation, making it ideal for sweaters, casual outerwear, and blankets that require warmth and softness. The choice between worsted and woolen wool depends on the desired texture, durability, and insulation properties for specific clothing or textile applications.

Care and Maintenance Requirements

Worsted wool, characterized by its tightly spun, smooth fibers, requires gentle handling such as hand washing in cold water or dry cleaning to maintain its sleek appearance and prevent shrinkage. Woolen wool, made from loosely spun fibers, benefits from careful cleaning methods including gentle washing and avoiding agitation to preserve its softness and loft. Both types should be air-dried flat to prevent distortion and fiber damage, ensuring longevity and maintaining fabric quality.

Choosing the Right Wool for Your Needs

Worsted wool features tightly spun fibers creating a smooth, durable fabric ideal for formal attire and tailored garments, while woolen wool has loosely spun fibers resulting in a softer, warmer texture suited for casual wear and insulation. Selecting the right wool depends on your garment's purpose: worsted for polished, wrinkle-resistant suits, and woolen for cozy, breathable sweaters or outerwear. Consider fiber density, fabric weight, and end-use performance to optimize comfort and style in your wool choice.

Worsted Wool vs Woolen Wool Infographic

materialdif.com

materialdif.com