Carding and combing are two essential processes in preparing wool fibers for spinning, each affecting the texture and quality of the final yarn. Carding aligns wool fibers into a loose, airy web, creating a softer, fuzzier yarn ideal for warmth and elasticity. Combing, on the other hand, removes shorter fibers and impurities while straightening longer fibers, resulting in a smoother, stronger, and more lustrous yarn suited for fine, high-quality fabrics.

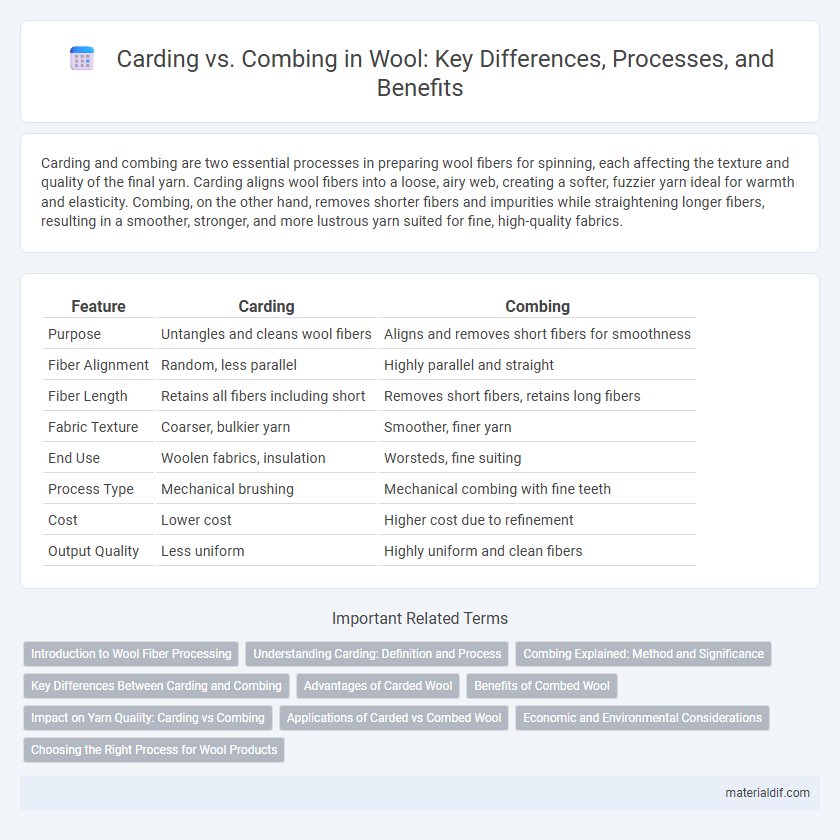

Table of Comparison

| Feature | Carding | Combing |

|---|---|---|

| Purpose | Untangles and cleans wool fibers | Aligns and removes short fibers for smoothness |

| Fiber Alignment | Random, less parallel | Highly parallel and straight |

| Fiber Length | Retains all fibers including short | Removes short fibers, retains long fibers |

| Fabric Texture | Coarser, bulkier yarn | Smoother, finer yarn |

| End Use | Woolen fabrics, insulation | Worsteds, fine suiting |

| Process Type | Mechanical brushing | Mechanical combing with fine teeth |

| Cost | Lower cost | Higher cost due to refinement |

| Output Quality | Less uniform | Highly uniform and clean fibers |

Introduction to Wool Fiber Processing

Carding and combing are essential wool fiber processing techniques that prepare raw wool for spinning by aligning fibers and removing impurities. Carding uses wire-toothed rollers to untangle and produce a loose web of fibers called a sliver, enhancing fiber openness and airflow. Combing further refines the sliver by removing short fibers and aligning longer fibers parallel, resulting in a smoother, stronger yarn preferred for fine, high-quality textiles.

Understanding Carding: Definition and Process

Carding is a mechanical process that disentangles, cleans, and intermixes wool fibers to produce a continuous web suitable for further processing. It involves passing wool through wire-toothed rollers that separate and align fibers, removing impurities and short fibers but leaving a less uniform fiber arrangement compared to combing. This technique is essential for creating woolen yarns with a soft texture, offering greater warmth and elasticity than combed wool.

Combing Explained: Method and Significance

Combing is a meticulous process in wool preparation that aligns fibers parallel to each other, removing short fibers and impurities for a smoother, stronger yarn. This method enhances the fabric's durability and sheen by producing longer, more uniform fibers ideal for fine woolen and worsted textiles. Combing's significance lies in its ability to create premium quality wool suitable for high-end garments, improving both texture and wearability.

Key Differences Between Carding and Combing

Carding and combing are two essential wool processing methods that prepare fibers for spinning by aligning and cleaning them. Carding disentangles and roughly aligns fibers using wire-covered rollers, producing a soft, airy web ideal for coarser yarns, while combing further refines the fiber alignment by removing short fibers and impurities, resulting in smoother, finer, and stronger yarns. The key differences lie in fiber alignment precision, removal of short fibers, and the texture of the final wool product, with combing producing a more uniform and high-quality fiber ideal for premium fabrics.

Advantages of Carded Wool

Carded wool offers increased bulk and loft, resulting in enhanced insulation and warmth properties, making it ideal for cozy textiles and outerwear. The carding process opens and aligns the fibers irregularly, which improves air retention and creates a softer hand-feel compared to combed wool. Carded wool also tends to be more affordable due to less processing, providing cost-effective versatility for a wide range of woolen products.

Benefits of Combed Wool

Combed wool undergoes a more thorough process that removes short fibers and impurities, resulting in a smoother, stronger, and more durable yarn compared to carded wool. This refinement enhances fabric quality by producing a finer texture with less pilling and improved elasticity, ideal for high-end garments and luxury textiles. The increased fiber alignment in combed wool also promotes better insulation and moisture-wicking properties, making it a preferred choice for performance and comfort.

Impact on Yarn Quality: Carding vs Combing

Carding fibers aligns and cleans wool but leaves shorter fibers and uneven strands, resulting in yarn with a slightly coarse texture and lower uniformity. Combing removes short fibers and impurities while straightening the long fibers, producing smoother, stronger, and finer yarn with superior strength and luster. Consequently, combed wool yarns are preferred for high-quality textiles demanding durability and a refined finish.

Applications of Carded vs Combed Wool

Carded wool, with its coarser texture and higher bulk, is commonly used in products like blankets, upholstery, and insulation where warmth and durability are prioritized over fineness. Combed wool, known for its smoothness and finer fibers, is preferred in high-quality garments such as suits, fine knitwear, and luxury textiles requiring superior softness and strength. The choice between carded and combed wool impacts the fabric's end-use, influencing factors such as texture, strength, and aesthetic appeal.

Economic and Environmental Considerations

Carding wool consumes less energy than combing, making it a more cost-effective option for large-scale textile production. Combing produces higher-quality wool by aligning fibers more uniformly, which increases the market value but also generates more waste and requires more water and chemicals. Balancing economic benefits with environmental impacts is crucial for sustainable wool processing strategies.

Choosing the Right Process for Wool Products

Carding creates a fluffy wool fiber web ideal for bulky yarns and insulation, while combing produces smooth, aligned fibers suited for fine, high-quality textiles. Selecting carding enhances wool products requiring softness and loft, whereas combing is essential for strength and clarity in premium fabrics. Understanding these processes ensures optimal texture and durability in wool product manufacturing.

Carding vs Combing Infographic

materialdif.com

materialdif.com