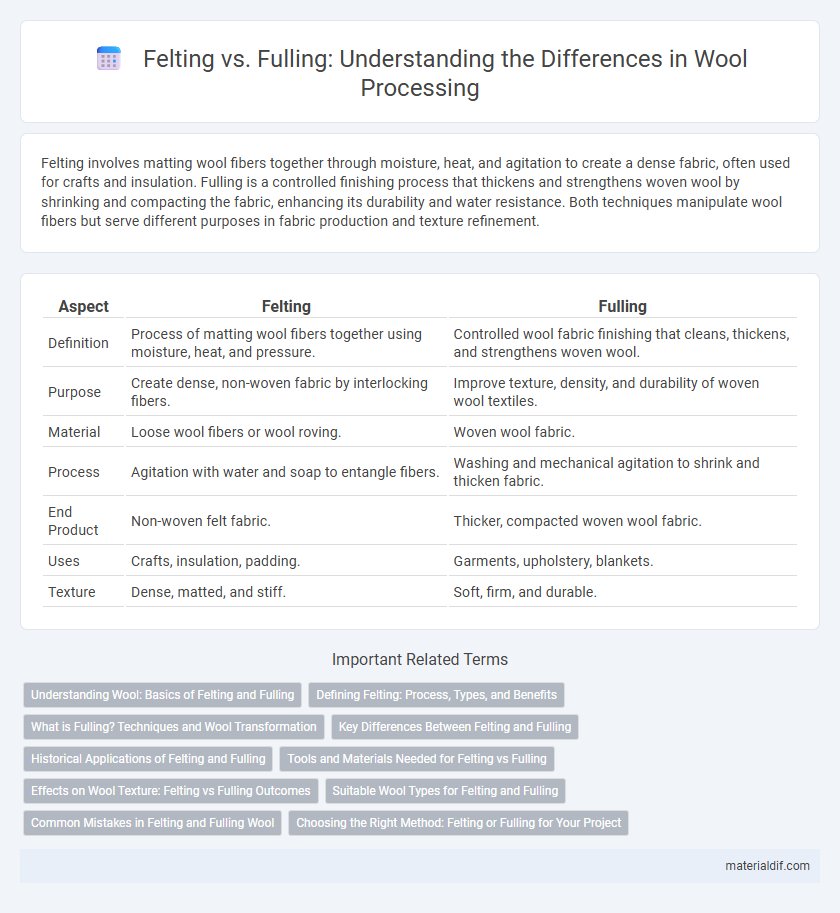

Felting involves matting wool fibers together through moisture, heat, and agitation to create a dense fabric, often used for crafts and insulation. Fulling is a controlled finishing process that thickens and strengthens woven wool by shrinking and compacting the fabric, enhancing its durability and water resistance. Both techniques manipulate wool fibers but serve different purposes in fabric production and texture refinement.

Table of Comparison

| Aspect | Felting | Fulling |

|---|---|---|

| Definition | Process of matting wool fibers together using moisture, heat, and pressure. | Controlled wool fabric finishing that cleans, thickens, and strengthens woven wool. |

| Purpose | Create dense, non-woven fabric by interlocking fibers. | Improve texture, density, and durability of woven wool textiles. |

| Material | Loose wool fibers or wool roving. | Woven wool fabric. |

| Process | Agitation with water and soap to entangle fibers. | Washing and mechanical agitation to shrink and thicken fabric. |

| End Product | Non-woven felt fabric. | Thicker, compacted woven wool fabric. |

| Uses | Crafts, insulation, padding. | Garments, upholstery, blankets. |

| Texture | Dense, matted, and stiff. | Soft, firm, and durable. |

Understanding Wool: Basics of Felting and Fulling

Felting transforms loose wool fibers into a dense fabric through heat, moisture, and agitation, binding the fibers without weaving or knitting. Fulling follows weaving, shrinking and thickening wool fabric by applying moisture, heat, and pressure to enhance durability and texture. Both processes fundamentally alter wool's structure, but felting starts with raw fibers while fulling refines woven material.

Defining Felting: Process, Types, and Benefits

Felting is a textile process that matts wool fibers together through heat, moisture, and pressure, creating a dense and durable fabric. There are various types of felting, including needle felting, wet felting, and nuno felting, each offering unique textures and applications. The benefits of felting include enhanced insulation, water resistance, and exceptional flexibility in crafting artistic or functional wool products.

What is Fulling? Techniques and Wool Transformation

Fulling is a traditional wool finishing process that involves moisture, heat, and mechanical agitation to mat wool fibers, enhancing fabric density and durability. Techniques include wet fulling, where wool is immersed in hot water and soap then agitated, and dry fulling, which uses friction and pressure to achieve similar effects. This transformation shrinks and thickens the wool, creating a compact, weather-resistant material ideal for textiles and garments.

Key Differences Between Felting and Fulling

Felting transforms wool fibers into a dense mat by applying heat, moisture, and pressure, causing the fibers to interlock naturally, while fulling is a controlled mechanical process used to thicken and strengthen woven wool fabric through moisture, heat, and agitation. Felting creates non-woven textile sheets primarily from loose fibers, whereas fulling enhances the texture and durability of existing woolen cloth. The key difference lies in felting producing a new fabric structure, and fulling refining and compacting already woven material.

Historical Applications of Felting and Fulling

Felting and fulling have distinct historical applications in wool processing, with felting dating back to ancient times as one of the earliest textile techniques used by nomadic cultures to create durable, warm garments and shelter. Fulling, which emerged later in medieval Europe, was a mechanized process that cleansed and thickened woven wool fabrics to produce dense, weather-resistant cloth, critical for trading and military purposes. Both methods significantly influenced the evolution of wool textiles, shaping regional economies and cultural practices from prehistoric Asia to Renaissance Europe.

Tools and Materials Needed for Felting vs Fulling

Felting requires materials such as loose wool fibers, felting needles, foam pads, and sometimes soap and water for wet felting, with tools designed to tangle the fibers through repeated needle punching or moisture agitation. Fulling involves finished woven or knitted wool fabric, hot water, soap, and mechanical agitation using hands, washing machines, or fulling mills to shrink and thicken the fabric. Felting tools emphasize fiber manipulation at a micro level, while fulling relies on fabric physical contraction for texture and density enhancement.

Effects on Wool Texture: Felting vs Fulling Outcomes

Felting compacts wool fibers through heat, moisture, and agitation, creating a dense, matted texture ideal for crafts and insulation. Fulling strengthens and thickens woven wool fabric by shrinking and interlocking fibers, enhancing durability and producing a smoother, more uniform surface. Both processes alter wool texture significantly, with felting yielding a coarse, rugged feel and fulling resulting in a refined, resilient finish.

Suitable Wool Types for Felting and Fulling

Felting is best suited for wool fibers with scales that can easily interlock, such as Merino and Corriedale, due to their fine, crimped texture. Fulling, on the other hand, is ideal for coarser, more robust wool types like Shetland or Icelandic wool, which contain longer staple fibers that shrink and mat together effectively. Both processes rely on the unique structural properties of wool fibers to create dense, durable fabrics, but the choice of wool type significantly influences the quality and texture of the finished product.

Common Mistakes in Felting and Fulling Wool

Common mistakes in felting wool include using water that is too hot or too cold, which can prevent proper fiber interlocking, and agitating the fibers excessively, leading to uneven texture or holes. In fulling wool, a frequent error is insufficient moisture or agitation, resulting in incomplete shrinkage and weak fabric cohesion, while over-fulling can cause excessive shrinkage and loss of fabric dimension. Proper control of temperature, moisture, and handling techniques is crucial to achieving desired texture and durability in both felting and fulling processes.

Choosing the Right Method: Felting or Fulling for Your Project

Felting creates a dense, non-woven fabric by matting wool fibers together using moisture, heat, and agitation, ideal for sculptural or decorative projects requiring detailed texture. Fulling, a controlled mechanical process, strengthens and shrinks woven or knitted wool fabric, enhancing durability and water resistance for garments and upholstery. Selecting between felting and fulling depends on your project's texture, structural needs, and final use, with felting offering handcrafted detail and fulling providing robust fabric reinforcement.

Felting vs Fulling Infographic

materialdif.com

materialdif.com