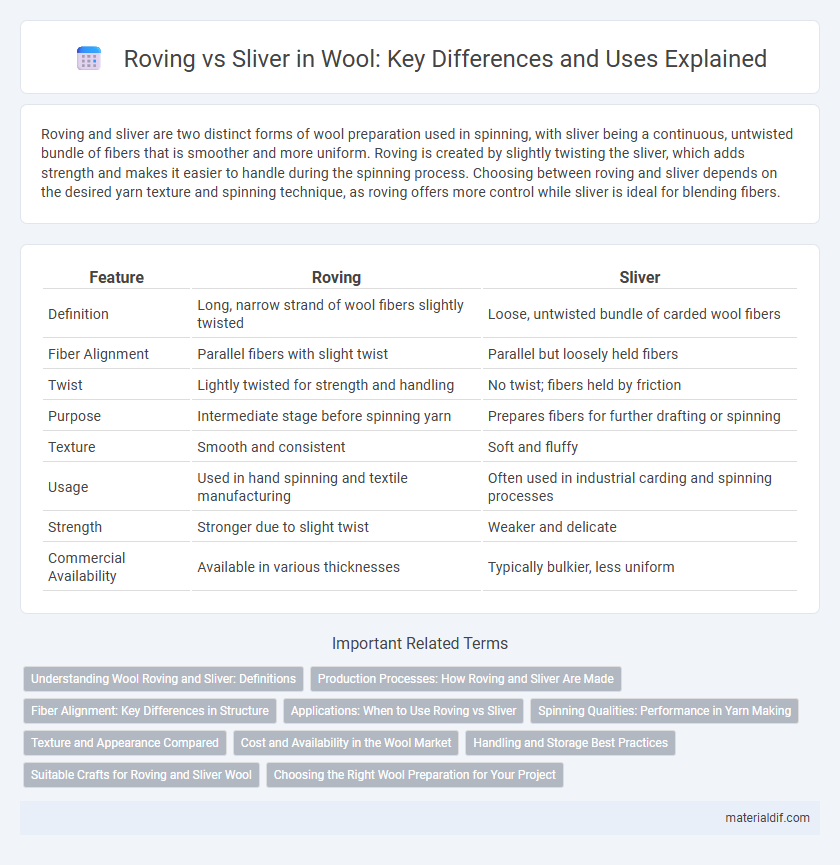

Roving and sliver are two distinct forms of wool preparation used in spinning, with sliver being a continuous, untwisted bundle of fibers that is smoother and more uniform. Roving is created by slightly twisting the sliver, which adds strength and makes it easier to handle during the spinning process. Choosing between roving and sliver depends on the desired yarn texture and spinning technique, as roving offers more control while sliver is ideal for blending fibers.

Table of Comparison

| Feature | Roving | Sliver |

|---|---|---|

| Definition | Long, narrow strand of wool fibers slightly twisted | Loose, untwisted bundle of carded wool fibers |

| Fiber Alignment | Parallel fibers with slight twist | Parallel but loosely held fibers |

| Twist | Lightly twisted for strength and handling | No twist; fibers held by friction |

| Purpose | Intermediate stage before spinning yarn | Prepares fibers for further drafting or spinning |

| Texture | Smooth and consistent | Soft and fluffy |

| Usage | Used in hand spinning and textile manufacturing | Often used in industrial carding and spinning processes |

| Strength | Stronger due to slight twist | Weaker and delicate |

| Commercial Availability | Available in various thicknesses | Typically bulkier, less uniform |

Understanding Wool Roving and Sliver: Definitions

Wool roving refers to fibers that have been carded, aligned, and slightly twisted into a continuous strand ideal for spinning and felting, providing a smooth texture and consistent thickness. In contrast, wool sliver is a long bundle of fiber that has been carded and aligned but remains untwisted, offering a softer, more airy form primarily used in spinning or blending processes. Understanding these distinctions helps in selecting the appropriate wool form for specific textile applications, ensuring optimal fiber handling and fabric quality.

Production Processes: How Roving and Sliver Are Made

Sliver is produced by carding raw wool fibers into continuous, untwisted strands to align and clean the fibers efficiently, serving as an intermediate step before further processing. Roving follows, created by slightly twisting the sliver to add strength and cohesion, preparing the fibers for spinning into yarn. Both processes involve precise machinery to ensure fiber quality and consistency in textile manufacturing.

Fiber Alignment: Key Differences in Structure

Roving and sliver differ primarily in fiber alignment and structure; roving consists of fibers drawn out and slightly twisted for added strength, making it ideal for spinning into yarn. Sliver features loosely aligned fibers without twist, maintaining a soft and fluffy texture suitable for further processing like carding or drafting. The degree of fiber alignment affects the ease of handling and the final yarn's strength and texture in textile production.

Applications: When to Use Roving vs Sliver

Roving is ideal for hand spinning, weaving, and knitting due to its slightly twisted, continuous strand that provides strength and consistency, making it suitable for producing durable yarns and fabrics. Sliver, characterized by its untwisted, loose fibers, is preferred for carding, blending, and preparatory stages in spinning, offering flexibility for custom fiber mixes and fine-tuning texture. Choosing roving or sliver depends on the desired end-use; roving supports finished textile production, while sliver excels in early processing and fiber manipulation.

Spinning Qualities: Performance in Yarn Making

Roving, characterized by its slightly twisted and compact fiber strands, offers improved strength and consistent draft during spinning, resulting in smoother and stronger yarns compared to sliver. Sliver, being a loose bundle of fibers without twist, allows easier blending and fiber alignment but requires careful handling to prevent breakage and irregular tension in yarn production. The choice between roving and sliver impacts yarn uniformity, tensile strength, and overall spinning efficiency in wool processing.

Texture and Appearance Compared

Roving wool features a slightly twisted texture, giving it a more defined and sturdy appearance, ideal for spinning and weaving. Sliver wool has a smooth, untwisted surface, resulting in a softer, more delicate look that is preferred for fine hand spinning and blending fibers. The choice between roving and sliver impacts the final fabric's texture, with roving offering more durability and sliver providing enhanced softness and subtle sheen.

Cost and Availability in the Wool Market

Roving typically costs more than sliver due to its additional processing, which enhances fiber alignment and prepares it for spinning, while sliver remains a more affordable option as a loosely assembled fiber bundle. Availability of sliver is generally higher in the wool market because it requires less refining, making it accessible for a broader range of textile manufacturers. Wool processors favor sliver for bulk production and budget-conscious projects, whereas roving is preferred in artisanal and specialty markets despite its premium price.

Handling and Storage Best Practices

Roving requires more careful handling due to its loose twist, making it prone to distortion and tangling during storage, which necessitates storing it in breathable, moisture-controlled environments to maintain fiber integrity. Sliver, being less twisted and more compact, benefits from being stored flat or rolled to prevent excessive compression that can deform fiber alignment, with humidity control crucial to avoid static buildup and fiber brittleness. Both forms need protection from direct sunlight and pests, ensuring optimal fiber quality for subsequent spinning or felting processes.

Suitable Crafts for Roving and Sliver Wool

Roving wool's loose, thick texture makes it ideal for hand spinning, felting, and chunky knitting projects, enhancing creativity in yarn crafts and bulky textiles. Sliver wool's smooth, continuous fibers are perfect for drum carding, blending with other fibers, and machine spinning, providing consistent fiber alignment for fine yarn production. Choosing between roving and sliver depends on the craft's fiber handling requirements and desired texture in the final product.

Choosing the Right Wool Preparation for Your Project

Roving consists of loosely twisted wool fibers ideal for hand spinning and felting projects that require a textured, airy finish, while sliver is a continuous, untwisted wool bundle suited for smooth, consistent spinning and weaving. Selecting roving enhances projects needing softness and loft, whereas sliver provides uniformity and strength for fine yarn production. Understanding the fiber preparation's impact on your project's texture, strength, and appearance ensures optimal results in wool crafting.

Roving vs Sliver Infographic

materialdif.com

materialdif.com