Felted wool is created by matting and compressing wool fibers using moisture, heat, and pressure, producing a dense and sturdy fabric ideal for crafts and insulation. Boiled wool undergoes a similar process but is specifically treated with hot water and agitation, resulting in a thicker, more durable, and slightly stretchable material perfect for outerwear and heavy garments. Both types offer excellent warmth and water resistance, but boiled wool's refined texture makes it preferable for tailored clothing.

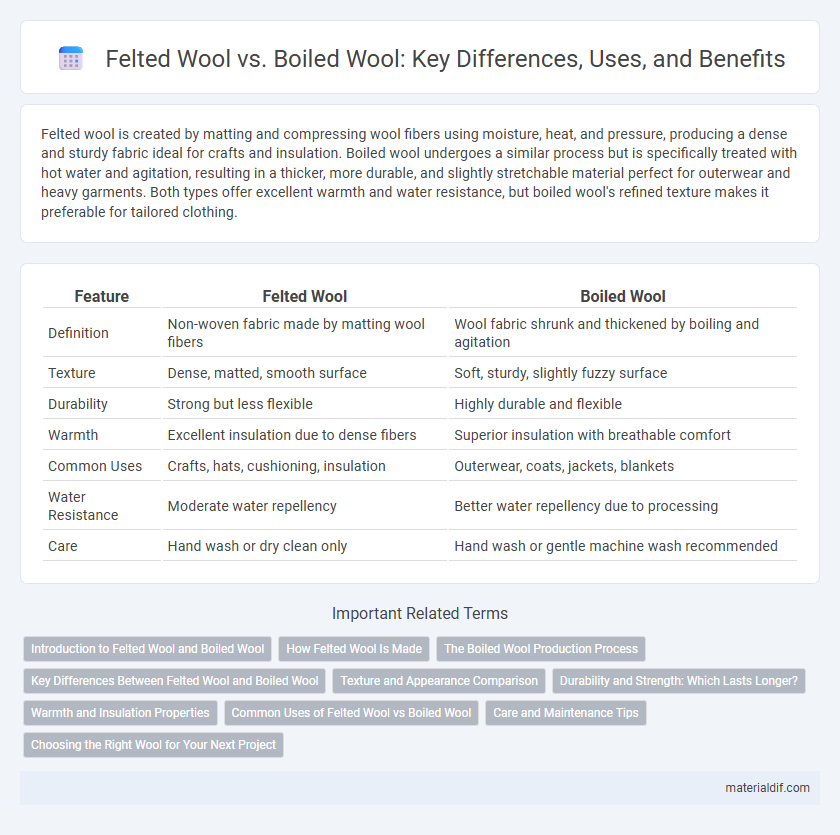

Table of Comparison

| Feature | Felted Wool | Boiled Wool |

|---|---|---|

| Definition | Non-woven fabric made by matting wool fibers | Wool fabric shrunk and thickened by boiling and agitation |

| Texture | Dense, matted, smooth surface | Soft, sturdy, slightly fuzzy surface |

| Durability | Strong but less flexible | Highly durable and flexible |

| Warmth | Excellent insulation due to dense fibers | Superior insulation with breathable comfort |

| Common Uses | Crafts, hats, cushioning, insulation | Outerwear, coats, jackets, blankets |

| Water Resistance | Moderate water repellency | Better water repellency due to processing |

| Care | Hand wash or dry clean only | Hand wash or gentle machine wash recommended |

Introduction to Felted Wool and Boiled Wool

Felted wool is created by matting, condensing, and pressing wool fibers together, resulting in a dense and durable fabric often used for crafts and insulation. Boiled wool undergoes a similar process but involves controlled heat and moisture, causing the fabric to shrink and tighten, enhancing its warmth and water resistance. Both types offer unique textures and functional benefits, making them popular choices in fashion and home textiles.

How Felted Wool Is Made

Felted wool is made by matting, condensing, and pressing wool fibers together using heat, moisture, and agitation, creating a dense and durable fabric. This process aligns and entangles the fibers without weaving or knitting, resulting in a material with a smooth surface and excellent insulation properties. Unlike boiled wool, which involves fulling woven wool fabric, felted wool is crafted directly from loose fibers, leading to its characteristic firmness and resilience.

The Boiled Wool Production Process

The boiled wool production process involves fulling, a technique where woven wool fabric is subjected to hot water, soap, and mechanical agitation to shrink and mat the fibers together, creating a dense and durable material. This method enhances the fabric's insulation, water resistance, and longevity compared to felted wool, which is made by directly matting loose wool fibers without weaving. Boiled wool maintains more structural integrity and flexibility, making it ideal for outerwear and heavyweight garments.

Key Differences Between Felted Wool and Boiled Wool

Felted wool is made by matting and compressing wool fibers together, resulting in a dense, non-woven fabric often used for crafts and insulation. Boiled wool, on the other hand, is a woven wool fabric that undergoes a controlled boiling process to shrink and thicken the material, enhancing its durability and water resistance. Key differences include the production methods--felted wool uses matting, while boiled wool uses woven fabric--and the resulting texture, where felted wool is generally stiffer and less flexible compared to the softer, more supple boiled wool.

Texture and Appearance Comparison

Felted wool features a dense, matted texture created by compressing wool fibers, resulting in a smooth, firm surface with limited elasticity. Boiled wool undergoes a fulling process that tightens the weave while retaining some softness and flexibility, giving it a slightly raised, textured appearance with subtle natural variations. Both types showcase warmth and durability, but felted wool is typically more rigid and uniform, whereas boiled wool maintains a plush, cozy feel with a more breathable structure.

Durability and Strength: Which Lasts Longer?

Felted wool is created by matting and compressing wool fibers, resulting in a dense fabric known for its excellent durability and tear resistance. Boiled wool undergoes a fulling process that tightens the fibers, enhancing strength and longevity while maintaining flexibility. While both types are durable, boiled wool typically lasts longer due to its tighter structure and resistance to pilling and fraying.

Warmth and Insulation Properties

Felted wool offers dense fiber matting that provides excellent warmth by trapping air pockets, enhancing insulation against cold temperatures. Boiled wool undergoes a controlled fulling process that tightens fibers, resulting in a thicker, more water-resistant fabric with superior heat retention. Both materials excel in thermal insulation, but boiled wool typically delivers greater wind resistance and moisture protection, ideal for outdoor winter wear.

Common Uses of Felted Wool vs Boiled Wool

Felted wool is commonly used for crafting, fashion accessories, and decorative items due to its dense, non-woven texture that provides durability and versatility. Boiled wool, created by fulling knitted wool fabric, is primarily used in outerwear like coats, jackets, and slippers because of its warmth, water resistance, and softness. Both types of wool serve distinct purposes, with felted wool favored for artistic and upholstery applications, while boiled wool excels in functional, everyday garments.

Care and Maintenance Tips

Felted wool requires gentle hand washing with cold water and mild detergent to preserve its dense texture, while boiled wool demands careful spot cleaning or dry cleaning to maintain its shape and avoid shrinking. Both fabrics should be air-dried flat away from direct heat sources to prevent distortion and preserve fiber integrity. Storing these wool types in breathable garment bags with cedar blocks helps repel pests and maintain freshness.

Choosing the Right Wool for Your Next Project

Felted wool, created by matting and compressing wool fibers, offers a dense, firm texture ideal for crafting and decorative projects, while boiled wool undergoes a fulling process that makes it thicker, more durable, and water-resistant, perfect for outerwear and accessories. When choosing the right wool, consider felted wool for lightweight, easy-to-shape items and boiled wool for garments requiring warmth and structure. Evaluating the end use, fiber density, and texture helps optimize project outcomes with the appropriate wool type.

Felted wool vs Boiled wool Infographic

materialdif.com

materialdif.com