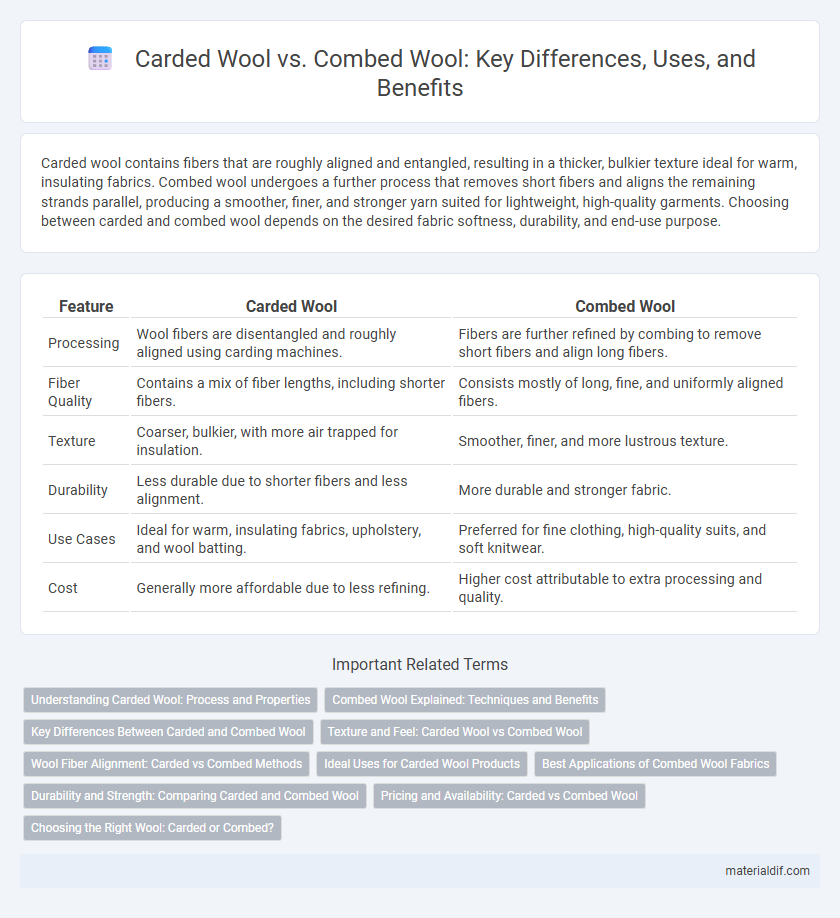

Carded wool contains fibers that are roughly aligned and entangled, resulting in a thicker, bulkier texture ideal for warm, insulating fabrics. Combed wool undergoes a further process that removes short fibers and aligns the remaining strands parallel, producing a smoother, finer, and stronger yarn suited for lightweight, high-quality garments. Choosing between carded and combed wool depends on the desired fabric softness, durability, and end-use purpose.

Table of Comparison

| Feature | Carded Wool | Combed Wool |

|---|---|---|

| Processing | Wool fibers are disentangled and roughly aligned using carding machines. | Fibers are further refined by combing to remove short fibers and align long fibers. |

| Fiber Quality | Contains a mix of fiber lengths, including shorter fibers. | Consists mostly of long, fine, and uniformly aligned fibers. |

| Texture | Coarser, bulkier, with more air trapped for insulation. | Smoother, finer, and more lustrous texture. |

| Durability | Less durable due to shorter fibers and less alignment. | More durable and stronger fabric. |

| Use Cases | Ideal for warm, insulating fabrics, upholstery, and wool batting. | Preferred for fine clothing, high-quality suits, and soft knitwear. |

| Cost | Generally more affordable due to less refining. | Higher cost attributable to extra processing and quality. |

Understanding Carded Wool: Process and Properties

Carded wool undergoes a mechanical process where fibers are disentangled and aligned using wire-toothed rollers, resulting in a loosely organized fiber web ideal for producing thicker, bulkier yarns. This process preserves shorter fibers and imparts a textured, loftier quality with enhanced warmth and resilience. Carded wool's open structure makes it suitable for blankets, sweaters, and felting, offering durability and elasticity distinct from the smoother, finer finish of combed wool.

Combed Wool Explained: Techniques and Benefits

Combed wool undergoes a meticulous process where fibers are aligned and shorter strands removed, resulting in a smoother, stronger, and more lustrous fabric compared to carded wool. This technique enhances durability and provides superior insulation, making combed wool ideal for high-quality garments and fine textiles. By eliminating impurities and creating uniform fiber length, combed wool offers greater softness and a refined appearance that boosts both comfort and aesthetic appeal.

Key Differences Between Carded and Combed Wool

Carded wool undergoes a process where fibers are disentangled and roughly aligned using carding machines, resulting in a coarser, fluffier texture suited for insulating or bulkier fabrics. Combed wool involves an additional combing step that removes short fibers and aligns the longer fibers more precisely, producing a smoother, stronger, and finer yarn ideal for high-quality garments. Key differences include fiber alignment, fiber length retention, and fabric texture, with combed wool offering superior softness, strength, and durability compared to carded wool.

Texture and Feel: Carded Wool vs Combed Wool

Carded wool has a coarser texture with a slightly rougher feel due to its loosely aligned fibers, making it ideal for producing bulky or textured fabrics. Combed wool features a smoother, softer texture as the combing process removes shorter fibers and straightens the strands, resulting in finer, more luxurious fabric. The tactile difference significantly impacts the end use, with carded wool suited for warmth and durability, while combed wool is preferred for softness and a sleek appearance.

Wool Fiber Alignment: Carded vs Combed Methods

Carded wool fibers are loosely aligned and retain more natural impurities, resulting in a thicker, fuzzier texture ideal for insulation and warmth. Combed wool undergoes a more refined process where fibers are aligned parallel, removing short fibers and debris to produce a smoother, stronger, and finer fabric. This precise fiber alignment in combed wool enhances durability and softness, making it preferred for high-quality garments and fine textiles.

Ideal Uses for Carded Wool Products

Carded wool is ideal for producing products that require a coarser texture and greater warmth, such as insulation, felt, and upholstery padding. The carding process aligns fibers loosely, making the wool breathable and resilient, perfect for blankets and heavy-duty outerwear. Its structure holds bulk well, providing excellent cushioning and thermal insulation for practical household and industrial uses.

Best Applications of Combed Wool Fabrics

Combed wool fabrics offer superior smoothness, strength, and uniformity due to the removal of short fibers and impurities during processing, making them ideal for high-quality suiting, fine knitwear, and luxury upholstery. Their enhanced durability and refined texture provide excellent drape and comfort in tailored garments and premium textile products. These properties make combed wool the preferred choice for applications requiring elegance, resilience, and a polished finish.

Durability and Strength: Comparing Carded and Combed Wool

Carded wool retains more short fibers and lanolin, resulting in a bulkier texture but lower strength and durability compared to combed wool. Combed wool undergoes a process that removes short fibers and aligns the remaining fibers parallel, producing a smoother, stronger, and more durable fabric. This makes combed wool ideal for high-quality garments that require longevity and resistance to wear.

Pricing and Availability: Carded vs Combed Wool

Carded wool is generally more affordable and widely available due to its simpler processing method, which involves cleaning and aligning fibers without removing shorter strands. Combed wool commands a higher price because its production includes an additional step of combing to remove short fibers, resulting in a finer, smoother texture ideal for premium garments. Availability of combed wool is more limited, often found in specialty markets or high-end textile suppliers compared to the broader market presence of carded wool.

Choosing the Right Wool: Carded or Combed?

Carded wool retains more natural fibers, making it ideal for producing warm, coarse textiles with a rustic texture, while combed wool undergoes additional processing to remove short fibers and impurities, resulting in a smoother, finer, and stronger yarn suited for high-quality garments. When choosing between carded and combed wool, consider the desired fabric softness, durability, and intended use; carded wool suits heavy-duty, insulating products, whereas combed wool is preferred for lightweight, breathable apparel. Understanding these differences enhances fabric selection for tailors, designers, and textile manufacturers aiming for optimal performance and comfort.

Carded Wool vs Combed Wool Infographic

materialdif.com

materialdif.com