Crimp refers to the natural waviness of wool fibers, influencing elasticity and insulation, while staple length measures the actual length of individual fibers, affecting spinning efficiency and yarn strength. A higher crimp count usually correlates with finer, softer wool, whereas longer staple lengths contribute to durability and smoothness in the finished textile. Understanding the balance between crimp and staple length is crucial for producing high-quality wool products tailored to specific uses.

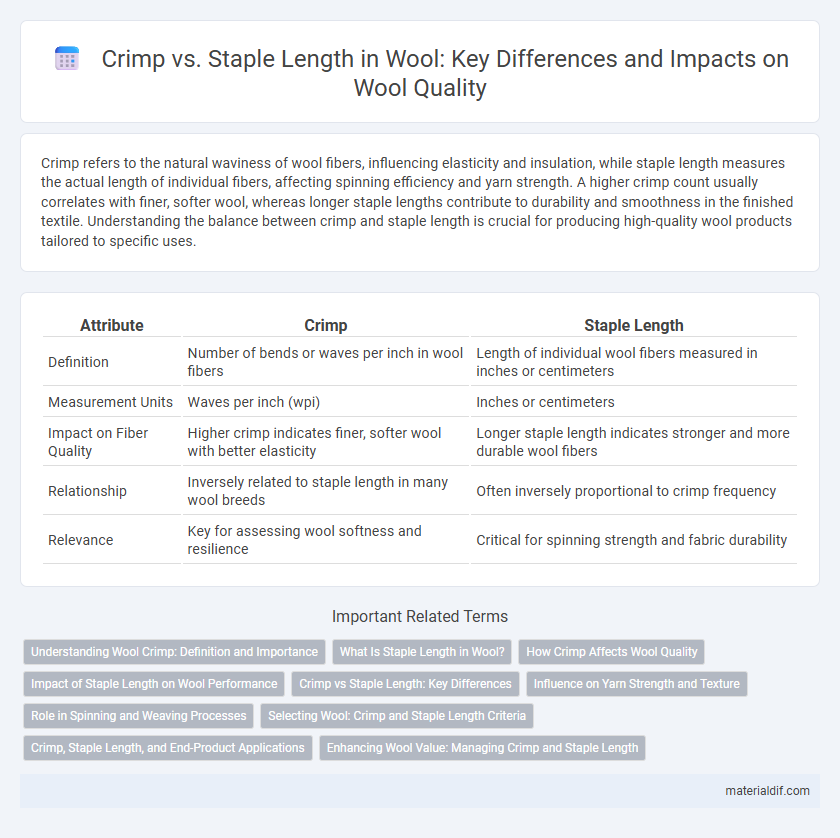

Table of Comparison

| Attribute | Crimp | Staple Length |

|---|---|---|

| Definition | Number of bends or waves per inch in wool fibers | Length of individual wool fibers measured in inches or centimeters |

| Measurement Units | Waves per inch (wpi) | Inches or centimeters |

| Impact on Fiber Quality | Higher crimp indicates finer, softer wool with better elasticity | Longer staple length indicates stronger and more durable wool fibers |

| Relationship | Inversely related to staple length in many wool breeds | Often inversely proportional to crimp frequency |

| Relevance | Key for assessing wool softness and resilience | Critical for spinning strength and fabric durability |

Understanding Wool Crimp: Definition and Importance

Wool crimp refers to the natural wave or bends found in individual wool fibers, directly influencing the fiber's elasticity, bulk, and insulation properties. Staple length measures the length of a wool fiber from end to end, affecting spinning efficiency and yarn strength. Understanding crimp is crucial for assessing wool quality, as higher crimp frequency generally correlates with finer, softer wool that enhances textile performance.

What Is Staple Length in Wool?

Staple length in wool refers to the average length of individual fibers measured from the skin surface to the fiber tip, typically ranging between 2 to 6 inches depending on breed and wool type. It directly influences fiber strength, processing efficiency, and the final fabric's texture and durability. Unlike crimp, which measures the natural waviness of wool fibers affecting elasticity, staple length primarily determines spinning performance and end-product quality.

How Crimp Affects Wool Quality

Crimp in wool fibers directly influences elasticity, loft, and insulation properties, enhancing softness and resilience in finished products. Higher crimp frequency typically correlates with finer, stronger wool, improving spinnability and fabric uniformity. Staple length complements crimp by affecting fiber strength and durability but is less impactful on tactile quality compared to the prominence of crimp in determining wool's overall performance.

Impact of Staple Length on Wool Performance

Staple length significantly affects wool performance by influencing fiber strength, processing efficiency, and final product quality. Longer staple fibers typically result in stronger yarns with enhanced durability and reduced fiber breakage during spinning, while shorter staples may cause increased fiber loss and lower yarn strength. Wool processing plants prioritize staple length to optimize production speed and improve the consistency of finished textiles such as garments and upholstery.

Crimp vs Staple Length: Key Differences

Crimp refers to the natural wave or bends in wool fibers, influencing elasticity and insulation, while staple length measures the actual length of the individual wool fibers. Crimp affects the fiber's ability to trap air and provide warmth, whereas staple length impacts the ease of spinning and fabric strength. High crimp wool tends to be softer and more elastic, whereas longer staple length wool is valued for durability and smoothness in finished textiles.

Influence on Yarn Strength and Texture

Crimp in wool fibers directly enhances yarn strength by increasing fiber cohesion and elasticity, resulting in a more durable and resilient texture. Conversely, staple length influences yarn smoothness and uniformity, with longer staples producing finer, silkier yarns ideal for high-quality textiles. The interplay between crimp and staple length determines the balance between strength and softness in the final wool product.

Role in Spinning and Weaving Processes

Crimp in wool fibers enhances elasticity and cohesion, improving fiber alignment during spinning for smoother yarn production. Staple length, the measured length of a wool fiber, directly impacts the strength and uniformity of the yarn, with longer staples producing more durable, finer threads ideal for weaving. Efficient spinning and weaving processes rely on balancing crimp and staple length to optimize fabric quality and performance.

Selecting Wool: Crimp and Staple Length Criteria

Selecting wool involves evaluating crimp and staple length, as these factors directly influence fiber quality and fabric performance. Wool with higher crimp frequency typically offers greater elasticity and insulation, while longer staple length contributes to strength and smoothness in the finished textile. Optimal selection balances crimp and staple to enhance durability, softness, and processing efficiency in wool products.

Crimp, Staple Length, and End-Product Applications

Crimp in wool refers to the natural waviness of fibers, directly influencing elasticity, loft, and insulation properties, while staple length measures the fiber's actual length, affecting yarn strength and smoothness. Higher crimp frequencies generally result in softer, more resilient fabrics ideal for insulation products and knitwear, whereas longer staple lengths contribute to durable, strong yarns suited to woven textiles and suits. Understanding the interaction between crimp and staple length is crucial for selecting the right wool grade tailored to end-product applications such as fine garments, upholstery, or industrial textiles.

Enhancing Wool Value: Managing Crimp and Staple Length

Effective management of crimp and staple length significantly enhances wool value by improving fiber quality and processing performance. Fine wool with well-defined crimp ensures elasticity and softness, while optimal staple length contributes to strength and ease of spinning. Balancing these factors leads to higher market prices and better textile outcomes.

Crimp vs Staple length Infographic

materialdif.com

materialdif.com