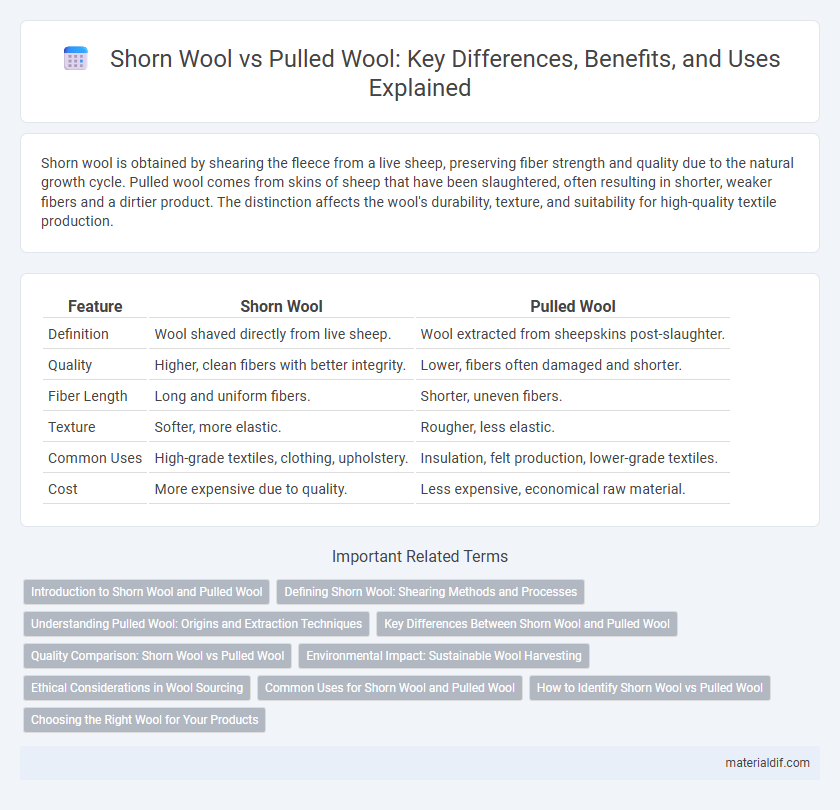

Shorn wool is obtained by shearing the fleece from a live sheep, preserving fiber strength and quality due to the natural growth cycle. Pulled wool comes from skins of sheep that have been slaughtered, often resulting in shorter, weaker fibers and a dirtier product. The distinction affects the wool's durability, texture, and suitability for high-quality textile production.

Table of Comparison

| Feature | Shorn Wool | Pulled Wool |

|---|---|---|

| Definition | Wool shaved directly from live sheep. | Wool extracted from sheepskins post-slaughter. |

| Quality | Higher, clean fibers with better integrity. | Lower, fibers often damaged and shorter. |

| Fiber Length | Long and uniform fibers. | Shorter, uneven fibers. |

| Texture | Softer, more elastic. | Rougher, less elastic. |

| Common Uses | High-grade textiles, clothing, upholstery. | Insulation, felt production, lower-grade textiles. |

| Cost | More expensive due to quality. | Less expensive, economical raw material. |

Introduction to Shorn Wool and Pulled Wool

Shorn wool is harvested directly by shearing sheep, resulting in longer, natural fibers prized for their strength and quality. Pulled wool is obtained from animal pelts after shearing or slaughter, typically featuring shorter fibers and more vegetable matter, making it less desirable for fine textiles. Understanding the distinction between shorn and pulled wool is crucial for selecting raw materials in wool processing and textile manufacturing.

Defining Shorn Wool: Shearing Methods and Processes

Shorn wool refers to fleece obtained by shearing sheep using specialized clippers or shears, typically in a controlled process that preserves fiber quality and length. The shearing method involves carefully removing the fleece in one piece, minimizing contamination and damage to the fibers, which is essential for high-grade textile production. This process contrasts with pulled wool, which is extracted from animals after natural shedding or slaughter, resulting in shorter, weaker fibers with more vegetable matter.

Understanding Pulled Wool: Origins and Extraction Techniques

Pulled wool is obtained by chemically or mechanically removing fleece from the hides of slaughtered sheep, primarily originating from animals that are no longer viable for shearing. Extraction techniques involve processes such as soaking hides in solutions to loosen the wool fibers before manual or machine removal, differing significantly from the traditional shearing method used for shorn wool. This method impacts the fiber quality, often resulting in shorter and coarser fibers compared to shorn wool, which affects its applications in textile manufacturing.

Key Differences Between Shorn Wool and Pulled Wool

Shorn wool is obtained by clipping the fleece directly from live sheep, preserving fiber strength, length, and natural lanolin content, making it ideal for high-quality textile production. Pulled wool, extracted from hides after slaughter, often contains shorter, coarser fibers with reduced elasticity and lanolin, resulting in lower durability and softness. These differences impact the end-use, with shorn wool favored for premium garments and pulled wool commonly used in industrial applications or lower-grade products.

Quality Comparison: Shorn Wool vs Pulled Wool

Shorn wool maintains superior fiber integrity and strength because it is carefully removed from live sheep, resulting in longer, stronger fibers ideal for high-quality textiles. Pulled wool, extracted from pelts after shearing or slaughter, often contains shorter, weaker fibers and reduced elasticity due to chemical processing and the animal's stress factors. This difference in fiber length and condition significantly impacts the softness, durability, and value of the final wool products.

Environmental Impact: Sustainable Wool Harvesting

Shorn wool, harvested by shearing sheep, supports sustainable wool production by allowing sheep to regrow fleece naturally, reducing waste and promoting animal welfare. Pulled wool, obtained from removing fleece from deceased animals, contributes to higher carbon footprints due to less frequent harvesting and increased resource use. Sustainable wool harvesting prioritizes shorn wool for its lower environmental impact and better integration into circular economy practices.

Ethical Considerations in Wool Sourcing

Shorn wool is harvested by carefully shearing sheep, ensuring animal welfare through minimal stress and injury, making it a more ethical choice compared to pulled wool, which is removed from animals that have died or been skinned, often raising concerns about animal cruelty and quality degradation. Ethical wool sourcing prioritizes sustainable practices, transparency in supply chains, and adherence to animal welfare standards such as those promoted by the Responsible Wool Standard (RWS). Consumers seeking ethical wool products should favor shorn wool verified by certification programs to support humane and environmentally responsible fiber production.

Common Uses for Shorn Wool and Pulled Wool

Shorn wool, harvested directly from live sheep, is commonly used in high-quality textile production, including clothing, blankets, and upholstery due to its long, strong fibers. Pulled wool, obtained from sheepskin after the animal is slaughtered, is typically utilized in carpet manufacturing, mattress stuffing, and insulation because of its shorter, coarser fibers. The distinct fiber qualities of shorn and pulled wool influence their suitability for different industrial applications and consumer products.

How to Identify Shorn Wool vs Pulled Wool

Shorn wool is obtained by cutting the fleece directly from live sheep, resulting in longer, uniform fibers with intact cuticles, whereas pulled wool comes from pelts of sheep that have been slaughtered, leading to shorter, brittle fibers often lacking natural lanolin. To identify shorn wool, examine the fiber length and integrity; shorn wool fibers are more elastic and retain natural oils, while pulled wool fibers tend to be uneven in length and feel drier and harsher. Microscopic analysis reveals shorn wool's intact cuticle scales, unlike pulled wool, which frequently shows damaged or missing scales due to processing after the animal's death.

Choosing the Right Wool for Your Products

Shorn wool, harvested by shearing live sheep, offers superior fiber strength, length, and quality, making it ideal for premium textiles and garments requiring durability and softness. Pulled wool, obtained from fleece removed post-slaughter, tends to be shorter, weaker, and more contaminated, suitable for lower-grade products like insulation or carpet padding. Selecting shorn wool ensures higher fiber integrity and value, whereas pulled wool suits cost-effective applications where fiber quality is less critical.

Shorn Wool vs Pulled Wool Infographic

materialdif.com

materialdif.com