Roving wool is a thick, slightly twisted strand of wool fibers ideal for spinning and felting, offering a dense texture and ease of handling. Sliver wool, on the other hand, consists of long, continuous bundles of parallel fibers that provide a smoother, finer base commonly used in carding and blending processes. Choosing between roving and sliver wool depends on the desired project's texture, strength, and fiber alignment requirements.

Table of Comparison

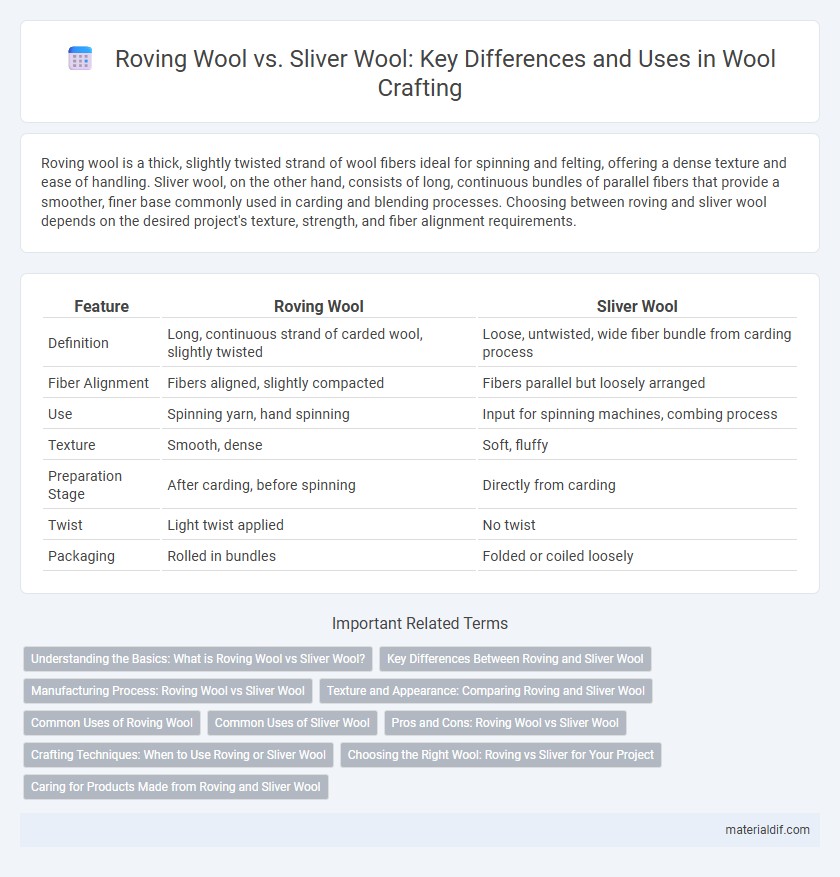

| Feature | Roving Wool | Sliver Wool |

|---|---|---|

| Definition | Long, continuous strand of carded wool, slightly twisted | Loose, untwisted, wide fiber bundle from carding process |

| Fiber Alignment | Fibers aligned, slightly compacted | Fibers parallel but loosely arranged |

| Use | Spinning yarn, hand spinning | Input for spinning machines, combing process |

| Texture | Smooth, dense | Soft, fluffy |

| Preparation Stage | After carding, before spinning | Directly from carding |

| Twist | Light twist applied | No twist |

| Packaging | Rolled in bundles | Folded or coiled loosely |

Understanding the Basics: What is Roving Wool vs Sliver Wool?

Roving wool consists of long, slightly twisted fibers aligned parallel, ideal for hand spinning and felting projects, providing strength and smoothness. Sliver wool is a continuous, untwisted rope of carded fibers, often used as a preparatory stage before spinning or weaving to maintain fiber alignment. Both forms optimize fiber arrangement but differ in twist and texture, impacting their suitability for various textile crafts.

Key Differences Between Roving and Sliver Wool

Roving wool features a thicker, loosely twisted fiber strand ideal for hand spinning and felting, while sliver wool consists of thinner, untwisted fibers arranged in continuous lengths for carding or further processing. The primary difference lies in texture and twist: roving is lightly spun for strength and ease of handling, whereas sliver maintains a smooth, aligned fiber structure without twist. These variations impact their suitability, with roving preferred for creating sturdy yarn and sliver favored in blending and preparing wool for commercial spinning.

Manufacturing Process: Roving Wool vs Sliver Wool

Roving wool is produced by drawing and slightly twisting fibers after carding, resulting in a continuous strand ideal for hand spinning and finer textile manufacturing. Sliver wool undergoes carding and combing to align fibers parallel without twisting, creating thick, loose bundles primarily used in machine spinning and blending applications. The manufacturing difference lies in roving's partial twist enhancing fiber cohesion, whereas sliver maintains a softer, untwisted form suitable for diverse yarn production.

Texture and Appearance: Comparing Roving and Sliver Wool

Roving wool features a thicker, more twisted texture that provides a rustic and bulky appearance, ideal for hand spinning and chunky knitting projects. Sliver wool, by contrast, is finer and smoother with a more consistent width, resulting in a sleek and uniform look preferred for delicate yarns and intricate weaving. The distinct differences in texture and appearance between roving and sliver wool influence their suitability for various textile crafts.

Common Uses of Roving Wool

Roving wool is commonly used for hand spinning, needle felting, and weaving due to its continuous, slightly twisted fibers that make it easy to draft and manipulate. Its thicker, elongated structure compared to sliver wool allows for creating textured yarns and bulky fabric, ideal for knitting scarves, hats, and chunky blankets. Roving wool is also favored in craft projects requiring sturdy fiber elements, such as wet felting and arm knitting.

Common Uses of Sliver Wool

Sliver wool, characterized by its continuous soft fiber strands, is commonly used in textile manufacturing for spinning fine yarns and weaving high-quality fabrics. It excels in creating smooth, even textures ideal for clothing, upholstery, and industrial textiles. Unlike roving wool, sliver wool provides consistent fiber alignment, enhancing durability and fabric strength.

Pros and Cons: Roving Wool vs Sliver Wool

Roving wool offers easier handling and is ideal for hand spinning due to its slightly twisted structure, but it can be less uniform and prone to drafts compared to sliver wool. Sliver wool provides consistent thickness and strength, making it perfect for machine spinning and producing smooth yarn, though it may be more challenging for beginners to manage. Choosing between roving and sliver wool depends on the spinner's skill level and the desired yarn texture or project requirements.

Crafting Techniques: When to Use Roving or Sliver Wool

Roving wool, with its thick, continuous fiber bundles, is ideal for spinning bulky yarns, needle felting, and arm knitting due to its loft and ease of handling. Sliver wool consists of thinner, parallel strands that work best for detailed hand carding, blending fibers, and creating fine, uniform yarns in spinning with wheel or spindle. Craft crafters choose roving wool for projects needing texture and volume, while sliver wool suits intricate designs requiring precision and smoothness.

Choosing the Right Wool: Roving vs Sliver for Your Project

Roving wool features a slightly twisted, thicker fiber bundle ideal for hand spinning and felting, offering strength and texture, whereas sliver wool is a loose, untwisted, and smooth fiber ideal for machine spinning and creating fine, consistent yarns. Choosing roving wool suits projects requiring robust, textured outcomes like chunky knits, while sliver wool excels in producing delicate, even fabrics such as lightweight garments. Consider your project's texture, durability, and spinning method to select the appropriate wool type.

Caring for Products Made from Roving and Sliver Wool

Products made from roving wool require gentle hand washing with mild detergent to maintain fiber alignment and prevent felting, as the loosely spun fibers are more delicate. Sliver wool items benefit from careful handling, preferably washing in cold water on a gentle cycle or hand washing, to preserve their smooth texture and loft. Both types should be laid flat to dry, avoiding wringing or twisting to retain the integrity and softness of the wool fibers.

Roving wool vs Sliver wool Infographic

materialdif.com

materialdif.com