Crimp refers to the natural waviness of wool fibers, which enhances elasticity and insulation by trapping air, while staple denotes the length of individual wool fibers crucial for spinning quality yarns. Wool with well-defined crimps tends to be springy and resilient, making it ideal for garments requiring stretch and warmth. Longer staple fibers improve strength and smoothness in the finished fabric, leading to durability and a finer texture.

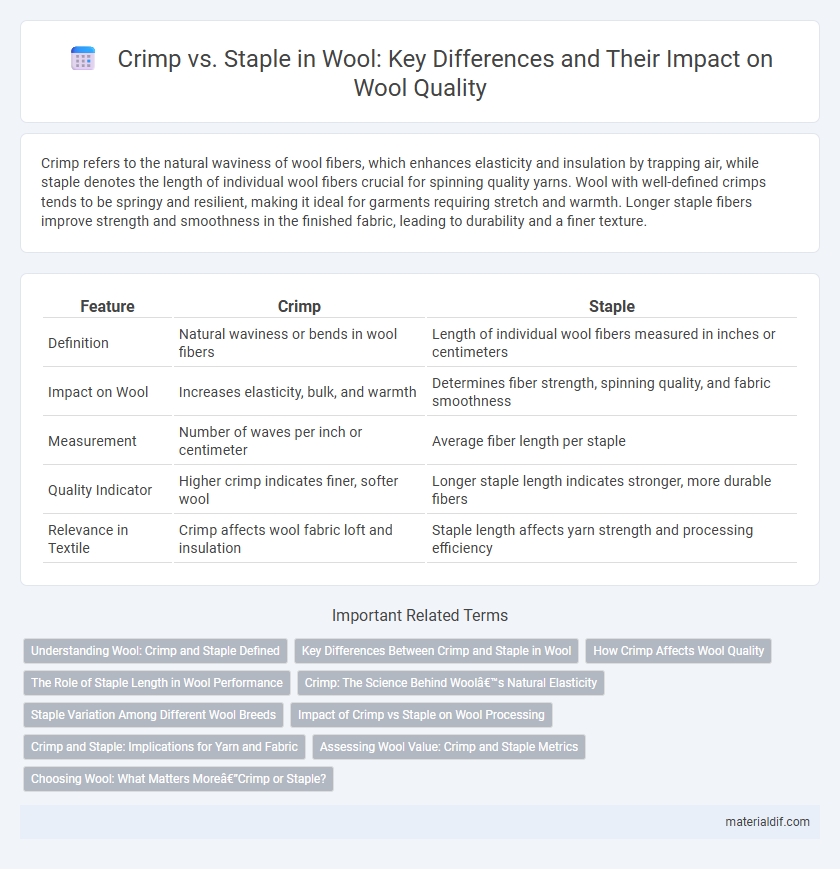

Table of Comparison

| Feature | Crimp | Staple |

|---|---|---|

| Definition | Natural waviness or bends in wool fibers | Length of individual wool fibers measured in inches or centimeters |

| Impact on Wool | Increases elasticity, bulk, and warmth | Determines fiber strength, spinning quality, and fabric smoothness |

| Measurement | Number of waves per inch or centimeter | Average fiber length per staple |

| Quality Indicator | Higher crimp indicates finer, softer wool | Longer staple length indicates stronger, more durable fibers |

| Relevance in Textile | Crimp affects wool fabric loft and insulation | Staple length affects yarn strength and processing efficiency |

Understanding Wool: Crimp and Staple Defined

Crimp refers to the natural wave or bends in individual wool fibers, influencing elasticity, bulk, and insulation properties crucial for high-quality textiles. Staple length measures the actual length of a bundle of wool fibers, affecting the fiber's spinning efficiency and yarn strength. Understanding both crimp and staple length is essential for evaluating wool's performance characteristics in fabric production and end-use durability.

Key Differences Between Crimp and Staple in Wool

Crimp in wool refers to the natural wave or bend in the fiber, which influences elasticity, insulation, and softness, whereas the staple is the length of an individual wool fiber, affecting spinning and yarn strength. Higher crimp frequencies generally indicate finer wool with superior loft and warmth, while longer staples contribute to better yarn durability and smoother fabric. Understanding these differences is essential for textile manufacturers aiming to optimize wool quality for specific applications such as apparel or upholstery.

How Crimp Affects Wool Quality

Crimp, the natural waviness of wool fibers, plays a crucial role in determining wool quality by influencing elasticity, loft, and insulation properties. Higher crimp frequency leads to finer, softer wool with better resilience and warmth retention, making it ideal for premium textile production. Conversely, wool with fewer crimps tends to be coarser and less elastic, reducing its suitability for high-end fabrics.

The Role of Staple Length in Wool Performance

Staple length significantly influences wool performance by affecting fiber strength, spinning efficiency, and yarn quality. Longer staples enhance fiber alignment and reduce fiber ends in the yarn, resulting in smoother, stronger textiles with increased durability. Shorter staples may cause more fiber ends protruding, leading to weaker yarns and more pilling in final wool products.

Crimp: The Science Behind Wool’s Natural Elasticity

Crimp refers to the natural wave or bend in wool fibers, which significantly contributes to wool's elasticity and resilience. This microscopic structure enables wool to stretch and recover without breaking, enhancing its durability and comfort in garments. Crimp density and uniformity directly influence the fiber's insulating properties and moisture management, making it a key factor in wool quality evaluation.

Staple Variation Among Different Wool Breeds

Staple length varies significantly among wool breeds, influencing fiber processing and textile quality. Merino wool typically features short, fine staples measuring 2 to 3 inches, while long-staple breeds like Lincoln or Romney produce fibers up to 8 inches, contributing to coarser yarns. This variation affects the wool's spinning properties, durability, and suitability for different fabric applications.

Impact of Crimp vs Staple on Wool Processing

Crimp in wool fibers, characterized by natural waves, enhances elasticity and bulk, improving spinning efficiency and yarn uniformity during wool processing. Staple length, the measurable length of individual fibers, directly influences combing and carding operations, with longer staples facilitating smoother processing and stronger yarns. Variations in crimp and staple length significantly affect fiber alignment, fiber cohesion, and overall yarn quality in textile manufacturing.

Crimp and Staple: Implications for Yarn and Fabric

Crimp in wool fibers refers to the natural waviness, which enhances yarn elasticity and improves fabric loft, providing insulation and softness. Staple length, the measured fiber length, affects yarn strength and uniformity, influencing fabric durability and texture. Understanding the balance between crimp and staple length is crucial for producing high-quality wool yarns and fabrics with desired performance characteristics.

Assessing Wool Value: Crimp and Staple Metrics

Crimp in wool refers to the natural wave or curl in the fiber, directly impacting elasticity and insulation properties, while staple length measures the length of individual wool fibers, influencing processing efficiency and yarn strength. High crimp frequency typically indicates finer, more elastic wool preferred for high-quality garments, whereas longer staple length ensures durability and ease in spinning. Accurate assessment of both crimp and staple length is essential for determining wool value, guiding pricing and end-use suitability in textile production.

Choosing Wool: What Matters More—Crimp or Staple?

Crimp refers to the natural wave or bends in wool fibers, influencing elasticity and insulation by trapping air, while staple length measures fiber length, affecting strength and spinning efficiency. Selecting wool for garments prioritizes crimp for softness and loft, whereas staple length suits textile manufacturing requiring durability. Understanding the balance between crimp and staple length guides optimal wool choice for specific end products like fine apparel or robust blankets.

Crimp vs Staple Infographic

materialdif.com

materialdif.com