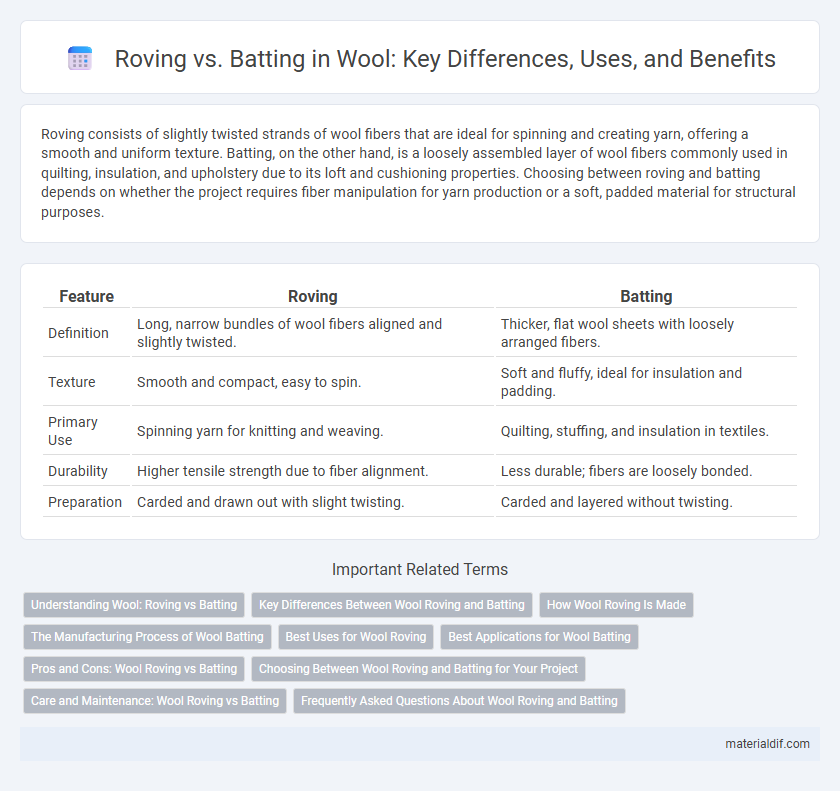

Roving consists of slightly twisted strands of wool fibers that are ideal for spinning and creating yarn, offering a smooth and uniform texture. Batting, on the other hand, is a loosely assembled layer of wool fibers commonly used in quilting, insulation, and upholstery due to its loft and cushioning properties. Choosing between roving and batting depends on whether the project requires fiber manipulation for yarn production or a soft, padded material for structural purposes.

Table of Comparison

| Feature | Roving | Batting |

|---|---|---|

| Definition | Long, narrow bundles of wool fibers aligned and slightly twisted. | Thicker, flat wool sheets with loosely arranged fibers. |

| Texture | Smooth and compact, easy to spin. | Soft and fluffy, ideal for insulation and padding. |

| Primary Use | Spinning yarn for knitting and weaving. | Quilting, stuffing, and insulation in textiles. |

| Durability | Higher tensile strength due to fiber alignment. | Less durable; fibers are loosely bonded. |

| Preparation | Carded and drawn out with slight twisting. | Carded and layered without twisting. |

Understanding Wool: Roving vs Batting

Roving and batting are both forms of processed wool used in spinning and felting but differ in texture and structure; roving consists of long, slightly twisted strands ideal for hand spinning, while batting is a thick, flat sheet suited for quilting and insulation. Roving's streamlined fibers allow for easier drafting and smoother yarn production, whereas batting's dense arrangement provides warmth and cushioning properties. Choosing between roving and batting depends on the intended project, with roving preferred for yarn creation and batting favored for bulky, insulating applications.

Key Differences Between Wool Roving and Batting

Wool roving consists of long, continuous strands of combed fibers ideal for spinning and detailed fiber arts, while wool batting is a thicker, fluffier layer of loose fibers primarily used for insulation and quilting. Roving provides more control and smoothness for creating yarn, whereas batting offers bulk and warmth without defined fiber alignment. The key difference lies in their structure and application: roving is streamlined for fiber manipulation, and batting serves as a soft, lofty filler.

How Wool Roving Is Made

Wool roving is created by carding raw wool fibers to align them parallel, removing impurities and short fibers, then gently drawing out the fibers into a continuous, cohesive strand. This process retains fiber length and strength, making roving ideal for spinning and felting projects. Unlike batting, which is heavily compressed and used for insulation or quilting, roving maintains a fluffy, airy texture suitable for handspinning into yarn.

The Manufacturing Process of Wool Batting

The manufacturing process of wool batting involves carding raw wool fibers to align and clean them before being layered into thick sheets or rolls, creating a uniform texture ideal for insulation and quilting. Unlike roving, which is drawn out into long, continuous strands for spinning, wool batting emphasizes fiber loft and thickness rather than length and twist. This process ensures wool batting maintains excellent thermal properties and cushioning, making it a preferred material in bedding and upholstery applications.

Best Uses for Wool Roving

Wool roving, characterized by its long, continuous fibers, is ideal for hand-spinning yarn, felting projects, and intricate needlework due to its smooth texture and consistent thickness. It excels in creating fine, detailed woolen fabrics and lightweight, durable textiles that retain warmth and flexibility. Artists and crafters prefer wool roving for its ability to be easily dyed and blended with other fibers.

Best Applications for Wool Batting

Wool batting excels in insulation and cushioning applications due to its loft and resilience, making it ideal for quilting, upholstery, and mattress pads. Its natural moisture-wicking and temperature-regulating properties enhance comfort in bedding and outerwear. Unlike roving, which is more suited for spinning and felting, wool batting provides uniform thickness and softness essential for layered textile constructions.

Pros and Cons: Wool Roving vs Batting

Wool roving offers dense fiber bundles ideal for detailed felting and spinning, providing better control and strength, but it can be more expensive and less airy than wool batting. Wool batting is lightweight, airy, and excellent for insulation and quilting, promoting warmth and ease of layering, though it may lack the firmness and precision required for fine textile projects. Choosing between wool roving and batting depends on whether the project demands structure and durability or softness and breathability.

Choosing Between Wool Roving and Batting for Your Project

Wool roving consists of long, continuous fibers ideal for spinning and felting projects requiring fine detail, while wool batting is made up of layered wool fibers compressed into a sheet, perfect for quilting and insulation. Selecting between roving and batting depends on the desired texture and function; roving offers more control for intricate work, whereas batting provides stability and warmth in larger craft applications. Understanding the fiber alignment and density in both types helps optimize project outcomes based on durability and appearance.

Care and Maintenance: Wool Roving vs Batting

Wool roving requires gentle handling and minimal agitation during washing to prevent felting and maintain fiber integrity, typically using cold water and mild detergents. Wool batting, being denser and more compact, needs careful drying on a flat surface to avoid distortion and shrinkage, preserving its loft and insulating properties. Both forms benefit from air drying away from direct heat and sunlight to enhance longevity and softness.

Frequently Asked Questions About Wool Roving and Batting

Wool roving is a long, narrow bundle of fiber often used for spinning and felting, while wool batting is a thicker layer of fibers commonly used for quilting and insulation. Frequently asked questions about wool roving address its smooth texture, ease of draft for spinning, and versatility in needle felting projects, whereas wool batting inquiries focus on its loft, warmth retention, and breathability for quilting and craft applications. Both materials vary in fiber length and processing method, influencing their specific uses and performance in textile crafts.

Roving vs Batting Infographic

materialdif.com

materialdif.com