Boiled wool is created by fulling woven wool, resulting in a dense, soft, and flexible fabric often used for outerwear and accessories. Melton wool undergoes a similar process but is tightly woven and heavily felted, producing a heavyweight, smooth-textured fabric with a dense nap that provides superior wind resistance and durability. Both fabrics offer warmth and insulation but differ in texture and structure, with boiled wool being softer and more pliable, while Melton wool is firmer and more structured.

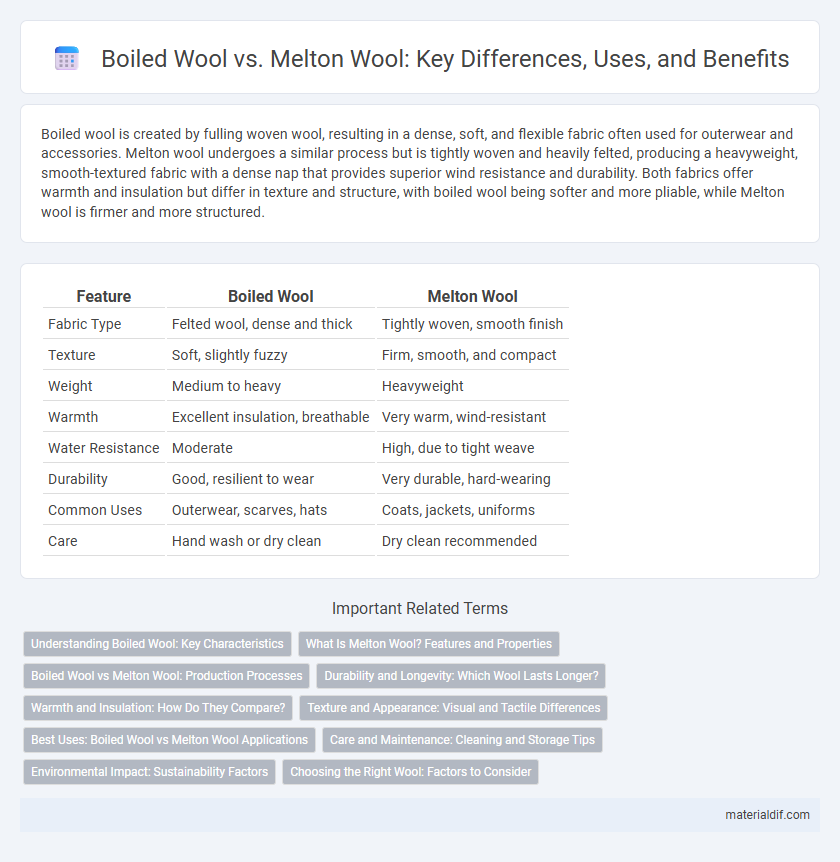

Table of Comparison

| Feature | Boiled Wool | Melton Wool |

|---|---|---|

| Fabric Type | Felted wool, dense and thick | Tightly woven, smooth finish |

| Texture | Soft, slightly fuzzy | Firm, smooth, and compact |

| Weight | Medium to heavy | Heavyweight |

| Warmth | Excellent insulation, breathable | Very warm, wind-resistant |

| Water Resistance | Moderate | High, due to tight weave |

| Durability | Good, resilient to wear | Very durable, hard-wearing |

| Common Uses | Outerwear, scarves, hats | Coats, jackets, uniforms |

| Care | Hand wash or dry clean | Dry clean recommended |

Understanding Boiled Wool: Key Characteristics

Boiled wool is a dense, non-woven fabric created by fulling and shrinking felted wool fibers, resulting in a thick, warm, and water-resistant material ideal for outerwear and accessories. Unlike Melton wool, boiled wool has a softer, more pliable texture with a slightly nubby surface, offering excellent insulation while maintaining breathability. Its unique production process enhances durability and resistance to fraying, making it a preferred choice for high-quality coats and blankets.

What Is Melton Wool? Features and Properties

Melton wool is a densely woven, tightly felted fabric traditionally made from wool fibers, characterized by its smooth surface and durability. It features a thick, heavy texture with a nap that provides excellent insulation and resistance to wind and water, making it ideal for outerwear like coats and jackets. The fabric's dense weave and felting process also enhance its wrinkle resistance and longevity compared to boiled wool, positioning Melton wool as a premium choice for warm, sturdy garments.

Boiled Wool vs Melton Wool: Production Processes

Boiled wool is created by subjecting woven wool fabric to hot water and mechanical agitation, causing the fibers to shrink and felt together, resulting in a dense, warm material. Melton wool undergoes a fulling process where the fabric is tightly woven and then heavily felted, producing a smooth, durable surface with a dense nap. The primary distinction lies in boiled wool's soft, flexible texture compared to Melton wool's structured, firm finish due to differences in felting intensity and weaving techniques.

Durability and Longevity: Which Wool Lasts Longer?

Boiled wool, created by fulling and pressing wool fibers, offers exceptional durability due to its dense, felted texture which resists wear and tear over time. Melton wool features a tightly woven, twill-weave fabric finished with a dense nap, providing strong resistance to wind and abrasion, making it highly durable as well. In terms of longevity, boiled wool tends to maintain its structure and shape longer under heavy use, whereas Melton wool excels in durability for outerwear exposed to harsh weather conditions.

Warmth and Insulation: How Do They Compare?

Boiled wool, created by fulling and shrinking wool fibers, offers excellent warmth due to its dense, felted texture that traps heat effectively. Melton wool, woven tightly and often brushed on one side, provides superior insulation and wind resistance, making it ideal for outerwear in cold climates. Both fabrics excel in warmth, but boiled wool emphasizes moisture-wicking and softness, while Melton wool prioritizes durability and windproof insulation.

Texture and Appearance: Visual and Tactile Differences

Boiled wool features a dense, felt-like texture with a slightly fuzzy surface, offering a soft, pliable feel ideal for cozy garments. Melton wool is tightly woven and heavily milled, producing a smooth, firm fabric with a clean, crisp appearance and a slight nap on the surface. Visually, boiled wool appears more matte and textured, while Melton showcases a polished finish with a refined, uniform look.

Best Uses: Boiled Wool vs Melton Wool Applications

Boiled wool, characterized by its dense and felted texture, excels in crafting warm garments like coats, hats, and mittens due to its excellent insulation and water-resistant properties. Melton wool, known for its tightly woven, smooth surface and durability, is ideal for outerwear such as military jackets, uniforms, and heavy-duty coats that require wind resistance and a polished appearance. Both fabrics serve distinct functions with boiled wool favored for soft, flexible insulation and Melton wool preferred for structured, weather-resistant apparel.

Care and Maintenance: Cleaning and Storage Tips

Boiled wool requires gentle hand washing or spot cleaning with cold water and mild detergent to maintain its dense, felted structure, while Melton wool, known for its tightly woven finish, can often be safely dry cleaned or gently machine washed on a wool cycle. Both types should be air-dried flat to prevent shrinking and maintain shape integrity. For storage, keep boiled and Melton wool garments in a cool, dry place with moth repellents like cedar blocks or lavender sachets to protect against fabric damage.

Environmental Impact: Sustainability Factors

Boiled wool, made by felting and shrinking woven wool fabric, uses minimal chemicals and requires less water, making it a more eco-friendly option compared to Melton wool. Melton wool undergoes a dense weaving and finishing process that can involve higher energy consumption and chemical treatments, increasing its environmental footprint. Both types are biodegradable and renewable, but boiled wool's simpler production enhances its overall sustainability.

Choosing the Right Wool: Factors to Consider

Boiled wool offers a dense, felted texture ideal for warmth and water resistance, making it suitable for outerwear and heavy garments, while Melton wool features a tightly woven, smooth surface with a refined finish preferred for structured coats and tailored apparel. Factors to consider when choosing between boiled wool and Melton wool include the desired level of insulation, breathability, fabric weight, and the garment's intended use or aesthetic. Evaluating durability and care requirements helps ensure the selected wool aligns with functional needs and style preferences.

Boiled Wool vs Melton Wool Infographic

materialdif.com

materialdif.com