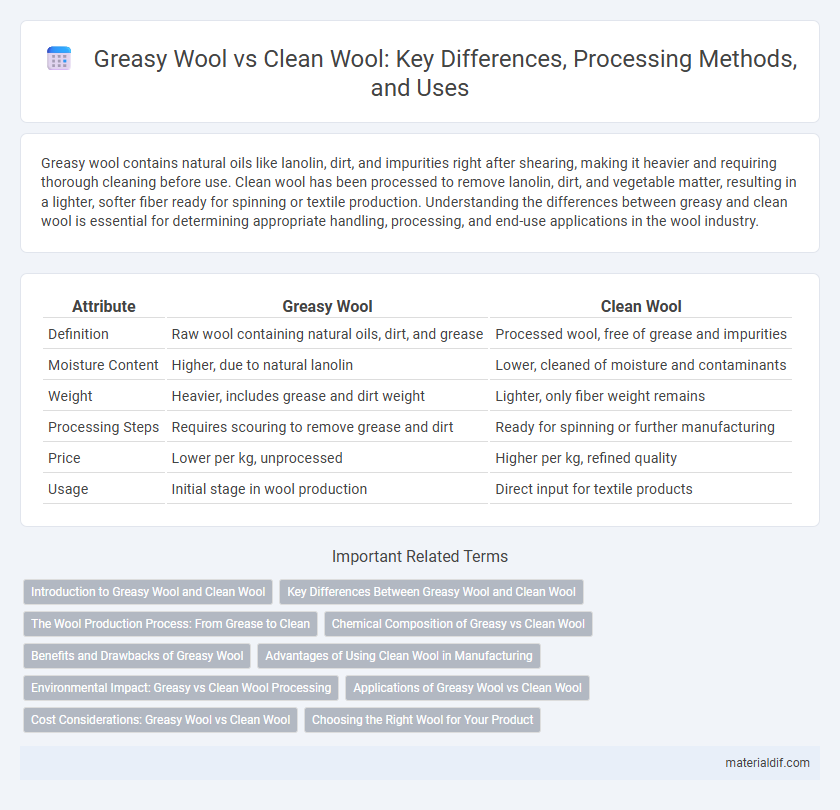

Greasy wool contains natural oils like lanolin, dirt, and impurities right after shearing, making it heavier and requiring thorough cleaning before use. Clean wool has been processed to remove lanolin, dirt, and vegetable matter, resulting in a lighter, softer fiber ready for spinning or textile production. Understanding the differences between greasy and clean wool is essential for determining appropriate handling, processing, and end-use applications in the wool industry.

Table of Comparison

| Attribute | Greasy Wool | Clean Wool |

|---|---|---|

| Definition | Raw wool containing natural oils, dirt, and grease | Processed wool, free of grease and impurities |

| Moisture Content | Higher, due to natural lanolin | Lower, cleaned of moisture and contaminants |

| Weight | Heavier, includes grease and dirt weight | Lighter, only fiber weight remains |

| Processing Steps | Requires scouring to remove grease and dirt | Ready for spinning or further manufacturing |

| Price | Lower per kg, unprocessed | Higher per kg, refined quality |

| Usage | Initial stage in wool production | Direct input for textile products |

Introduction to Greasy Wool and Clean Wool

Greasy wool, also known as raw wool, contains natural oils like lanolin, dirt, and vegetable matter directly from the sheep's fleece. Clean wool has undergone scouring processes to remove impurities, resulting in a softer texture suitable for spinning and textile production. Understanding the distinction between greasy and clean wool is essential for optimizing wool processing and product quality.

Key Differences Between Greasy Wool and Clean Wool

Greasy wool contains natural oils such as lanolin, dirt, and vegetable matter directly from the sheep, contributing to its heavier, oily texture and higher moisture content. Clean wool has undergone scouring to remove these impurities, resulting in a lighter, softer fiber that is ready for processing or spinning. This difference significantly impacts the wool's weight, quality, and suitability for various textile applications.

The Wool Production Process: From Grease to Clean

Greasy wool is the raw fleece shorn directly from sheep, containing natural oils like lanolin, dirt, and sweat residues. The wool production process involves scouring, where greasy wool undergoes washing to remove impurities and produce clean wool ready for spinning. Clean wool boasts enhanced fiber quality, improved dye uptake, and better texture for textile manufacturing.

Chemical Composition of Greasy vs Clean Wool

Greasy wool contains natural contaminants such as lanolin, dirt, sweat salts, and suint, significantly influencing its chemical composition with higher lipid and mineral content compared to clean wool. Clean wool, after scouring, exhibits reduced levels of lanolin (approximately 1-3%) and mineral matter, resulting in a higher proportion of keratin protein, which constitutes about 95% of its dry weight. Understanding these chemical differences is essential for optimizing processing techniques and enhancing the quality of wool fibers for textile production.

Benefits and Drawbacks of Greasy Wool

Greasy wool retains natural lanolin and impurities, providing superior protection and moisture resistance during storage and transport, which helps maintain fiber integrity. However, it requires extensive scouring to remove oils and dirt before processing, increasing production costs and environmental impact due to water and chemical use. The presence of lanolin in greasy wool offers antimicrobial properties and enhances fiber softness, contributing to higher quality end products after proper cleaning.

Advantages of Using Clean Wool in Manufacturing

Clean wool offers superior quality by reducing impurities such as lanolin, dirt, and vegetable matter, enhancing the efficiency of textile manufacturing processes. Its consistent fiber length and diameter improve the spinning performance, leading to stronger, smoother, and more uniform yarns. The reduced need for extensive scouring lowers production costs and environmental impact, making clean wool an economically and ecologically advantageous choice.

Environmental Impact: Greasy vs Clean Wool Processing

Greasy wool processing has a higher environmental impact due to the extensive water and chemical usage needed for scouring to remove lanolin, dirt, and contaminants. Clean wool reduces processing inputs, lowering water consumption and chemical discharge, which minimizes pollution in wastewater treatment systems. Choosing clean wool over greasy wool supports sustainability by decreasing energy use and greenhouse gas emissions associated with intensive cleaning.

Applications of Greasy Wool vs Clean Wool

Greasy wool, containing natural lanolin and impurities, is primarily used in industrial processes such as felt production, insulation, and mattress stuffing, where raw fiber properties are beneficial. Clean wool, fully scoured to remove grease and contaminants, is preferred in textile manufacturing for producing high-quality yarns, garments, and luxury fabrics due to its softness and uniformity. The choice between greasy and clean wool impacts the end product's performance, durability, and application suitability across various wool-based industries.

Cost Considerations: Greasy Wool vs Clean Wool

Greasy wool retains natural oils, dirt, and contaminants, making it less processed but bulkier and heavier, which generally results in lower initial purchase costs compared to clean wool. Clean wool, having undergone scouring to remove impurities, has higher processing expenses but offers consistent quality and less shrinkage, often justifying its premium price in textile production. Understanding the balance between upfront savings and long-term value is essential when evaluating cost considerations for greasy versus clean wool.

Choosing the Right Wool for Your Product

Greasy wool retains natural lanolin and impurities, offering superior water resistance and insulation, ideal for products requiring durability and weather protection. Clean wool, fully scoured to remove lanolin and contaminants, provides a softer texture and enhanced dye absorption, making it suitable for fine textiles and garments. Selecting the right wool depends on the desired end-use, with greasy wool favored in rugged applications and clean wool preferred for comfort and aesthetics.

Greasy Wool vs Clean Wool Infographic

materialdif.com

materialdif.com