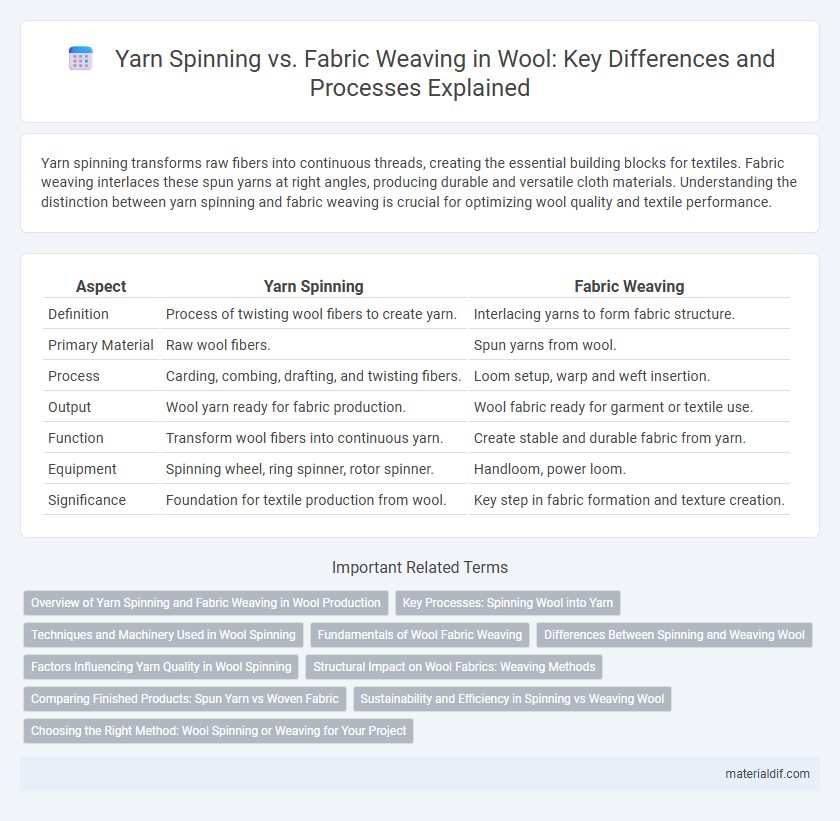

Yarn spinning transforms raw fibers into continuous threads, creating the essential building blocks for textiles. Fabric weaving interlaces these spun yarns at right angles, producing durable and versatile cloth materials. Understanding the distinction between yarn spinning and fabric weaving is crucial for optimizing wool quality and textile performance.

Table of Comparison

| Aspect | Yarn Spinning | Fabric Weaving |

|---|---|---|

| Definition | Process of twisting wool fibers to create yarn. | Interlacing yarns to form fabric structure. |

| Primary Material | Raw wool fibers. | Spun yarns from wool. |

| Process | Carding, combing, drafting, and twisting fibers. | Loom setup, warp and weft insertion. |

| Output | Wool yarn ready for fabric production. | Wool fabric ready for garment or textile use. |

| Function | Transform wool fibers into continuous yarn. | Create stable and durable fabric from yarn. |

| Equipment | Spinning wheel, ring spinner, rotor spinner. | Handloom, power loom. |

| Significance | Foundation for textile production from wool. | Key step in fabric formation and texture creation. |

Overview of Yarn Spinning and Fabric Weaving in Wool Production

Yarn spinning transforms raw wool fibers into continuous threads through processes like carding, drawing, and twisting, enhancing fiber alignment and strength for textile creation. Fabric weaving interlaces these yarns in warp and weft directions on a loom, producing durable woolen fabrics with varied textures and patterns. Both techniques are crucial in wool production, delivering material versatility and quality for garments and home textiles.

Key Processes: Spinning Wool into Yarn

Yarn spinning involves transforming raw wool fibers into continuous strands by carding, drawing, and twisting, which aligns the fibers and adds strength. This process enhances the wool's tensile strength and prepares it for subsequent fabric weaving, ensuring uniformity and durability in the final textile. Spinning quality directly impacts the texture and resilience of woven wool fabrics.

Techniques and Machinery Used in Wool Spinning

Wool spinning utilizes specialized machinery such as spinning frames, carding machines, and drawing frames to transform raw wool fibers into yarn through processes like carding, combing, and drafting, enabling consistent fiber alignment and strength. Techniques in wool spinning include worsted and woolen spinning, which differ in fiber preparation and yarn texture, with worsted using combed fibers for smooth, strong yarn and woolen employing carded fibers for a softer, bulkier yarn. Unlike fabric weaving that interlaces yarns to create fabric, wool spinning focuses on producing high-quality yarn suitable for diverse textile applications.

Fundamentals of Wool Fabric Weaving

Wool fabric weaving transforms yarns into durable textiles by interlacing warp and weft threads, creating diverse textures essential for garments and upholstery. The fundamentals involve precise control of wool yarn tension and loom settings to maintain fabric strength and elasticity. Understanding the properties of wool fibers, such as crimp and scale structure, is crucial for optimizing weave patterns and achieving desired fabric performance.

Differences Between Spinning and Weaving Wool

Yarn spinning transforms raw wool fibers into continuous threads by aligning and twisting them, which enhances strength and uniformity in the yarn. Fabric weaving interlaces these spun yarns perpendicularly on a loom to create structured textile surfaces with specific patterns and textures. The key difference lies in spinning producing yarn from fibers, while weaving forms fabric from yarn, each process critical to wool textile production.

Factors Influencing Yarn Quality in Wool Spinning

Yarn quality in wool spinning is primarily influenced by fiber length, fineness, and cleanliness, which determine the strength and smoothness of the yarn. The twist level during spinning affects the yarn's durability and elasticity, while consistent tension ensures uniform thickness. Environmental factors such as humidity and temperature also play critical roles in maintaining fiber integrity and preventing breakage during the spinning process.

Structural Impact on Wool Fabrics: Weaving Methods

Yarn spinning transforms raw wool fibers into continuous threads, influencing the yarn's strength and texture, while fabric weaving arranges these yarns into structured patterns that determine the fabric's durability and flexibility. Different weaving methods like plain weave, twill, and satin weave create varied surface textures and tensile properties, directly impacting the wool fabric's performance and aesthetic appeal. The structural interplay between spun yarn quality and chosen weaving technique is crucial for optimizing wool fabric resilience and drape.

Comparing Finished Products: Spun Yarn vs Woven Fabric

Spun yarn consists of tightly twisted fibers that create a continuous thread with high tensile strength and flexibility, making it ideal for knitting or weaving. Woven fabric, produced by interlacing two sets of yarns at right angles, offers enhanced durability, dimensional stability, and a smooth surface suited for garments and upholstery. The key difference lies in yarn's linear form, which enables versatility in textile production, while woven fabric provides structural integrity and a finished appearance.

Sustainability and Efficiency in Spinning vs Weaving Wool

Yarn spinning from wool often requires less water and energy compared to fabric weaving, making it a more sustainable process in raw material preparation. Spinning transforms raw wool fibers into yarn with minimal waste, while weaving typically involves greater energy consumption due to complex machinery and fabric density requirements. Efficient wool spinning techniques enhance fiber utilization and reduce resource input, promoting eco-friendly textile production over traditional weaving methods.

Choosing the Right Method: Wool Spinning or Weaving for Your Project

Selecting the appropriate method between wool yarn spinning and fabric weaving depends on the desired texture, durability, and function of the final product. Wool spinning transforms raw fibers into yarn, offering flexibility in thickness and softness for projects like knitting or crochet, while fabric weaving interlaces yarns to produce a sturdy, structured material ideal for garments or upholstery. Evaluating factors such as project complexity, end-use requirements, and wool fiber type ensures the best technique enhances both performance and aesthetic appeal.

Yarn Spinning vs Fabric Weaving Infographic

materialdif.com

materialdif.com