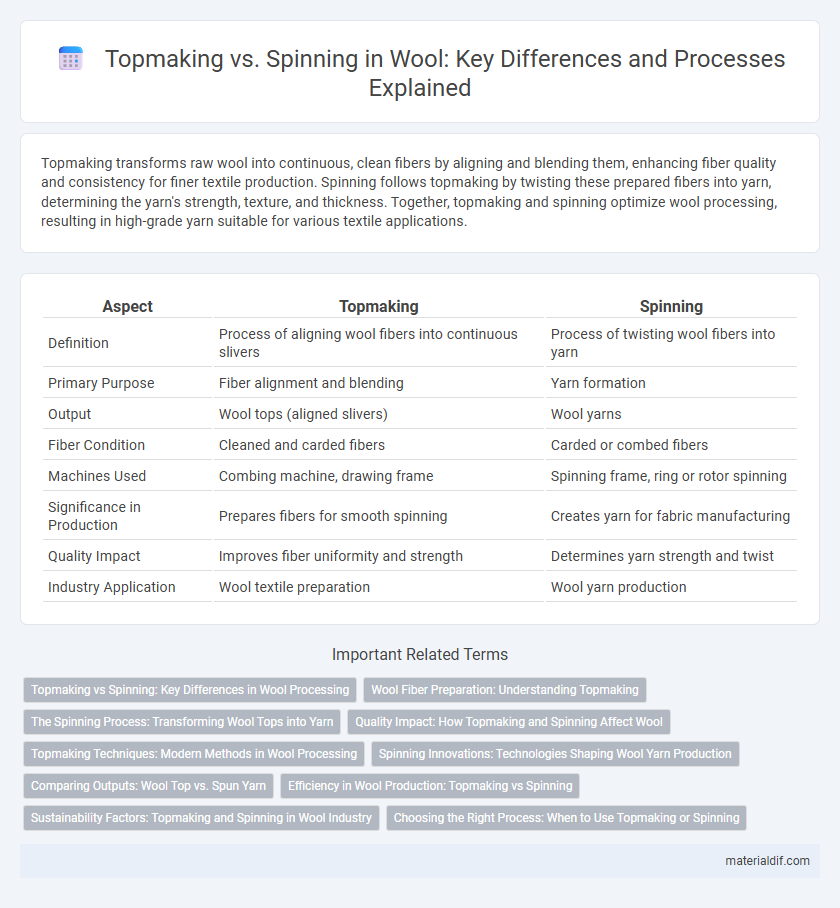

Topmaking transforms raw wool into continuous, clean fibers by aligning and blending them, enhancing fiber quality and consistency for finer textile production. Spinning follows topmaking by twisting these prepared fibers into yarn, determining the yarn's strength, texture, and thickness. Together, topmaking and spinning optimize wool processing, resulting in high-grade yarn suitable for various textile applications.

Table of Comparison

| Aspect | Topmaking | Spinning |

|---|---|---|

| Definition | Process of aligning wool fibers into continuous slivers | Process of twisting wool fibers into yarn |

| Primary Purpose | Fiber alignment and blending | Yarn formation |

| Output | Wool tops (aligned slivers) | Wool yarns |

| Fiber Condition | Cleaned and carded fibers | Carded or combed fibers |

| Machines Used | Combing machine, drawing frame | Spinning frame, ring or rotor spinning |

| Significance in Production | Prepares fibers for smooth spinning | Creates yarn for fabric manufacturing |

| Quality Impact | Improves fiber uniformity and strength | Determines yarn strength and twist |

| Industry Application | Wool textile preparation | Wool yarn production |

Topmaking vs Spinning: Key Differences in Wool Processing

Topmaking refines wool fibers by aligning and cleaning them into continuous, smooth slivers, optimizing fiber orientation for subsequent spinning. Spinning transforms these prepared fibers into yarn through twisting, blending strength and elasticity essential for fabric production. The primary difference lies in topmaking's role as a preparatory process enhancing fiber uniformity, while spinning converts fiber slivers into durable yarns suitable for weaving or knitting.

Wool Fiber Preparation: Understanding Topmaking

Topmaking in wool fiber preparation involves aligning and cleaning fibers to create a continuous, smooth sliver, essential for producing high-quality yarn with consistent strength and texture. Unlike spinning, which twists the fibers into yarn, topmaking ensures fibers are parallel and free from impurities, optimizing the yarn's durability and appearance. This process directly influences the final fabric's softness and uniformity, making it a critical step in wool textile manufacturing.

The Spinning Process: Transforming Wool Tops into Yarn

The spinning process converts wool tops into continuous yarn by drawing out and twisting fibers to enhance strength and uniformity. High-quality tops produced through topmaking ensure consistent fiber alignment, which is crucial for producing smooth, durable yarn. Spinning machinery, such as ring or rotor spinners, plays a vital role in controlling tension and twist to achieve desired yarn properties for textile applications.

Quality Impact: How Topmaking and Spinning Affect Wool

Topmaking improves wool quality by aligning fibers uniformly, resulting in smoother, stronger yarn with enhanced consistency. Spinning affects wool's strength and elasticity by controlling twist levels, directly impacting the fabric's durability and texture. Both processes are crucial for optimizing wool's final quality, with topmaking setting the foundation and spinning refining the fiber characteristics.

Topmaking Techniques: Modern Methods in Wool Processing

Topmaking in wool processing involves refining fibers into continuous slivers, ensuring uniformity and quality before spinning. Modern topmaking techniques utilize advanced combing machines that remove short fibers and impurities, enhancing fiber alignment for superior yarn strength and consistency. These innovations optimize productivity and produce high-grade wool tops essential for premium textile manufacturing.

Spinning Innovations: Technologies Shaping Wool Yarn Production

Spinning innovations in wool yarn production include advanced ring spinning, open-end spinning, and air-jet spinning technologies that enhance fiber alignment, yarn strength, and production speed. Integration of computer-controlled systems enables real-time monitoring and adjustments, reducing waste and ensuring consistent yarn quality. These technologies facilitate the creation of finer, stronger, and more uniform wool yarns, meeting the high standards of modern textile manufacturing.

Comparing Outputs: Wool Top vs. Spun Yarn

Wool top offers a long, continuous fiber alignment ideal for smooth, high-quality fabric production, while spun yarn consists of twisted short fibers providing greater strength and elasticity. The topmaking process yields a more uniform and refined output, suited for worsted fabrics, whereas spinning produces versatile yarns with varied textures used in both worsted and woolen textiles. Comparing outputs, wool top is favored for luxurious, durable cloth, while spun yarn excels in stretchability and resilience across diverse textile applications.

Efficiency in Wool Production: Topmaking vs Spinning

Topmaking enhances efficiency in wool production by converting carded fiber into uniform slivers, facilitating smoother downstream processes and reducing waste. Spinning transforms these prepared fibers into yarn, with advancements optimizing twist control and production speed to meet high-volume demands. Integrating topmaking with spinning technology streamlines operations, significantly increasing throughput and yarn quality in wool manufacturing.

Sustainability Factors: Topmaking and Spinning in Wool Industry

Topmaking in the wool industry involves straightening and aligning fibers, producing high-quality rovings with minimal material waste, enhancing sustainability by reducing defects and enhancing yarn efficiency. Spinning converts these rovings into yarn, where advanced techniques lower energy consumption and optimize fiber utilization, decreasing environmental impact. Sustainable practices in both topmaking and spinning contribute significantly to reducing water use, chemical inputs, and carbon footprint across the wool supply chain.

Choosing the Right Process: When to Use Topmaking or Spinning

Topmaking is ideal for producing long, smooth wool fibers used in worsted fabrics, offering strength and a fine finish, while spinning suits shorter fibers for woolen textiles that require softness and warmth. Selecting topmaking is advantageous when uniformity and durability are priorities in high-quality garments, whereas spinning is preferred for versatile, cozy fabrics with a fluffy texture. Understanding fiber length, desired fabric characteristics, and end-use ensures the right process is chosen to maximize wool's natural properties.

Topmaking vs Spinning Infographic

materialdif.com

materialdif.com