Wool pilling occurs when small fiber balls form on the surface of wool fabrics due to friction, while wool felting involves fibers matting together into a dense, compact texture caused by heat, moisture, and agitation. Pilling primarily affects the appearance, making the fabric look worn, whereas felting permanently alters the fabric's structure and thickness. Understanding the difference helps in proper care and maintenance to prolong the life of wool garments.

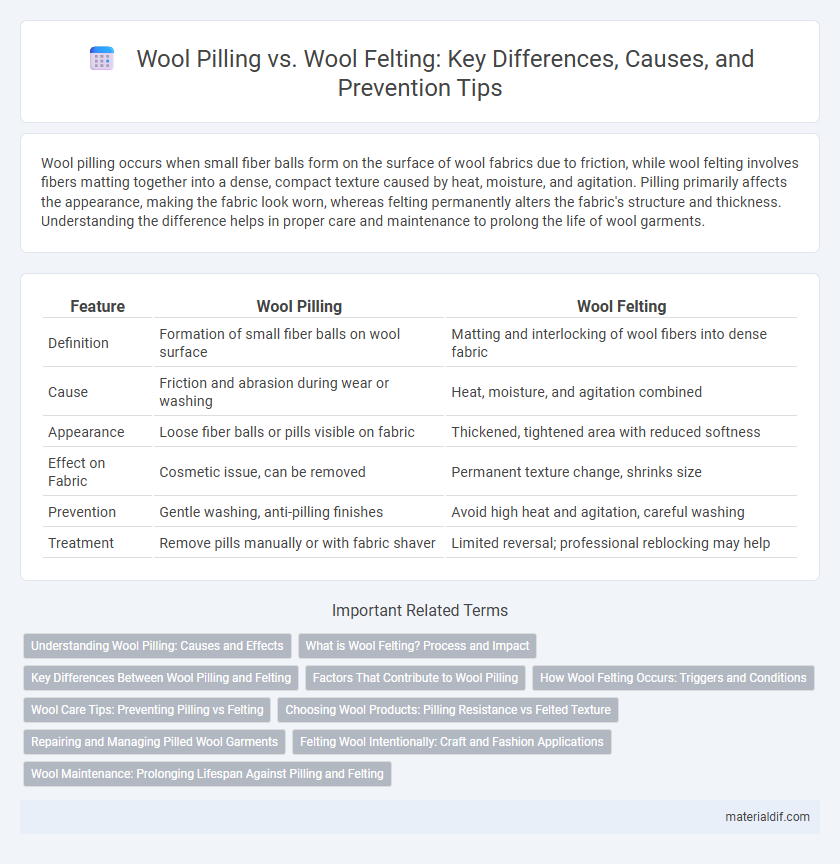

Table of Comparison

| Feature | Wool Pilling | Wool Felting |

|---|---|---|

| Definition | Formation of small fiber balls on wool surface | Matting and interlocking of wool fibers into dense fabric |

| Cause | Friction and abrasion during wear or washing | Heat, moisture, and agitation combined |

| Appearance | Loose fiber balls or pills visible on fabric | Thickened, tightened area with reduced softness |

| Effect on Fabric | Cosmetic issue, can be removed | Permanent texture change, shrinks size |

| Prevention | Gentle washing, anti-pilling finishes | Avoid high heat and agitation, careful washing |

| Treatment | Remove pills manually or with fabric shaver | Limited reversal; professional reblocking may help |

Understanding Wool Pilling: Causes and Effects

Wool pilling occurs when fibers break loose from the fabric surface, forming small, tangled balls due to friction and abrasion during wear and washing. This common phenomenon reduces the fabric's smoothness and aesthetic appeal, often signaling fiber weakness or low-quality yarn construction. Understanding wool pilling helps in selecting high-quality wool products and implementing proper care to maintain fabric durability and appearance.

What is Wool Felting? Process and Impact

Wool felting is a process where wool fibers are subjected to heat, moisture, and agitation, causing them to interlock and form a dense, compact fabric. This transformation results from the scales on the wool fibers matting together, permanently altering the textile's texture and structure. Wool felting enhances fabric durability and insulation but reduces softness and flexibility due to fiber entanglement.

Key Differences Between Wool Pilling and Felting

Wool pilling occurs when small fibers break loose and form tiny balls on the fabric's surface due to friction, while wool felting involves the matting and shrinking of fibers caused by heat, moisture, and agitation. Pilling primarily affects the garment's appearance and texture, whereas felting changes the fabric's structure and size permanently. Understanding these differences helps in selecting appropriate care methods to maintain wool's quality and longevity.

Factors That Contribute to Wool Pilling

Wool pilling occurs due to fibers breaking and tangling on the fabric surface, influenced by factors such as fiber length, yarn twist, and abrasion during wear. Shorter fibers and low twist yarns tend to pill more because loose fibers are more easily dislodged. Frequent friction in areas like cuffs and underarms accelerates fiber breakage, significantly contributing to wool pilling.

How Wool Felting Occurs: Triggers and Conditions

Wool felting occurs when wool fibers are exposed to heat, moisture, and agitation, causing the scales on the fibers to interlock and shrink. This process is often triggered by washing wool in hot water or vigorous mechanical action, which disrupts the fiber structure. Felting results in a dense, compact fabric distinct from pilling, where fibers form loose balls on the surface.

Wool Care Tips: Preventing Pilling vs Felting

To prevent wool pilling, turn garments inside out before washing, use a gentle cycle with cold water, and avoid friction from rough surfaces. To avoid felting, wash wool items separately in lukewarm water with mild detergent, and reshape them while damp to maintain fiber integrity. Proper storage in breathable bags and regular brushing with a soft garment brush can extend wool's lifespan by minimizing both pilling and felting.

Choosing Wool Products: Pilling Resistance vs Felted Texture

Wool pilling occurs when fibers break and form small balls on the fabric surface, which can affect the garment's appearance and comfort, while wool felting results from heat, moisture, and agitation causing fibers to mat and shrink, creating a dense, textured fabric. Choosing wool products with pilling resistance involves selecting tightly spun yarns and longer staple fibers, preferred for smooth, durable knitwear. Opt for felted wool when seeking a firm, structured texture ideal for accessories, outerwear, or crafts where warmth and wind resistance are priorities.

Repairing and Managing Pilled Wool Garments

Repairing pilled wool garments involves carefully removing the small balls of fiber caused by friction, using specialized fabric shavers or fine scissors to restore a smooth surface without damaging the fabric. Managing pilled wool requires minimizing friction during wear and washing, such as using gentle cycles and placing garments in protective laundry bags to prevent further fiber degradation. Unlike felting, which irreversibly alters wool fiber structure through heat and agitation, pilling can be effectively treated and managed to prolong the garment's lifespan.

Felting Wool Intentionally: Craft and Fashion Applications

Felting wool intentionally involves matting and compressing wool fibers to create a dense, sturdy fabric often used in crafts and fashion design for items like hats, bags, and slippers. This controlled process differs from wool pilling, which is an unwanted effect caused by fiber abrasion and results in small, fuzzy balls on the fabric surface. Felting enhances the wool's durability and texture, making it ideal for artistic applications and structured garments.

Wool Maintenance: Prolonging Lifespan Against Pilling and Felting

Wool pilling occurs when fibers break and tangle into small balls on the fabric's surface, while wool felting results from heat, moisture, and agitation causing fibers to mat and shrink. To maintain wool and prolong its lifespan, use gentle washing techniques with cold water and mild detergents, avoid excessive friction, and air dry flat to prevent fiber damage and deformation. Proper storage in cool, dry conditions and occasional brushing can further reduce pilling and maintain the integrity of the wool fibers.

Wool Pilling vs Wool Felting Infographic

materialdif.com

materialdif.com