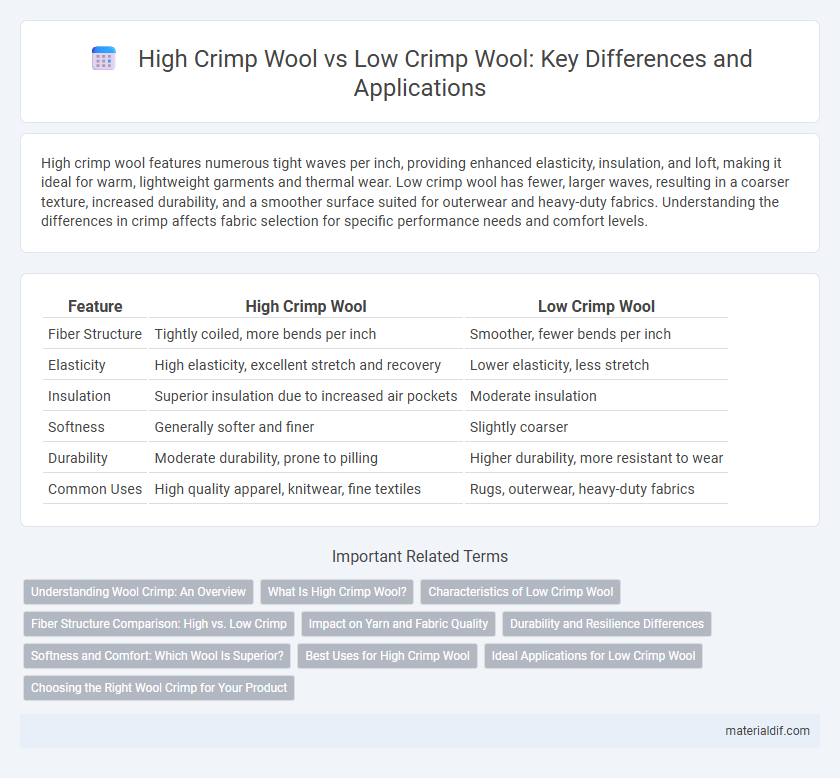

High crimp wool features numerous tight waves per inch, providing enhanced elasticity, insulation, and loft, making it ideal for warm, lightweight garments and thermal wear. Low crimp wool has fewer, larger waves, resulting in a coarser texture, increased durability, and a smoother surface suited for outerwear and heavy-duty fabrics. Understanding the differences in crimp affects fabric selection for specific performance needs and comfort levels.

Table of Comparison

| Feature | High Crimp Wool | Low Crimp Wool |

|---|---|---|

| Fiber Structure | Tightly coiled, more bends per inch | Smoother, fewer bends per inch |

| Elasticity | High elasticity, excellent stretch and recovery | Lower elasticity, less stretch |

| Insulation | Superior insulation due to increased air pockets | Moderate insulation |

| Softness | Generally softer and finer | Slightly coarser |

| Durability | Moderate durability, prone to pilling | Higher durability, more resistant to wear |

| Common Uses | High quality apparel, knitwear, fine textiles | Rugs, outerwear, heavy-duty fabrics |

Understanding Wool Crimp: An Overview

Wool crimp refers to the natural waves or bends in wool fibers, significantly influencing the fiber's elasticity, insulation, and softness. High crimp wool features numerous tight bends per inch, enhancing loft and thermal insulation, making it ideal for warm, breathable garments. Low crimp wool, with fewer bends, offers smoother texture and durability, preferred for outerwear and heavy-duty textiles.

What Is High Crimp Wool?

High crimp wool features a greater number of bends or waves per inch in the fiber, resulting in increased elasticity and loft. This type of wool provides superior insulation and resilience, making it ideal for garments requiring warmth and flexibility. High crimp fibers also enhance moisture-wicking properties, contributing to overall comfort in various weather conditions.

Characteristics of Low Crimp Wool

Low crimp wool features fewer bends or waves per inch, resulting in fibers that are straighter and less elastic compared to high crimp wool. This type of wool tends to be smoother, finer, and more resilient, providing enhanced durability and a lustrous appearance in textiles. Low crimp wool is ideal for producing tightly woven fabrics, offering excellent drape and resistance to pilling.

Fiber Structure Comparison: High vs. Low Crimp

High crimp wool fibers exhibit numerous bends and waves per inch, resulting in increased elasticity, loft, and insulation properties ideal for thermal garments. Low crimp wool features fewer bends, producing smoother, stronger fibers that enhance durability and tensile strength for fabrics requiring robustness. The fiber structure differences influence processing techniques, with high crimp wool demanding gentler handling to preserve softness, while low crimp wool allows for tighter weaving and higher abrasion resistance.

Impact on Yarn and Fabric Quality

High crimp wool fibers create yarns with increased elasticity, bulk, and softness, enhancing fabric loft and warmth. Low crimp wool produces smoother, stronger yarns, resulting in fabrics with better tensile strength and durability but less stretch. The choice between high and low crimp wool directly impacts yarn resilience, fabric texture, and performance characteristics.

Durability and Resilience Differences

High crimp wool fibers exhibit greater elasticity and spring-back ability, contributing to superior resilience and resistance to deformation under stress. Low crimp wool typically has longer, straighter fibers, making it less durable and more prone to permanent creasing or wear over time. The natural crimps in high crimp wool create air pockets that enhance breathability while maintaining structural integrity, leading to enhanced longevity in textile applications.

Softness and Comfort: Which Wool Is Superior?

High crimp wool features tightly curled fibers that trap more air, enhancing softness and insulation, which makes it superior for comfort in cold climates. Low crimp wool has straighter fibers, providing a smoother texture but less loft, resulting in a firmer feel that might be less comfortable for sensitive skin. The increased elasticity and resilience of high crimp wool contribute significantly to its superior softness and overall comfort compared to low crimp varieties.

Best Uses for High Crimp Wool

High crimp wool features tightly packed, highly elastic fibers that provide exceptional insulation and resilience, making it ideal for thermal garments and performance wear. Its superior loft and moisture-wicking properties enhance comfort in activewear and outdoor clothing, where breathability and temperature regulation are crucial. High crimp wool is also preferred in upholstery and bedding for its durability and natural springiness, offering long-lasting cushioning and warmth.

Ideal Applications for Low Crimp Wool

Low crimp wool, characterized by fewer waves per inch, provides a smoother texture and greater durability, making it ideal for outerwear, upholstery, and hard-wearing textiles. Its reduced elasticity and enhanced resilience suit applications requiring strength and minimal shrinkage. Low crimp wool is favored in products like suits, coats, and carpets where structural stability and resistance to wear are essential.

Choosing the Right Wool Crimp for Your Product

High crimp wool offers superior elasticity and loft, making it ideal for insulating products like winter clothing and bedding, where warmth and resilience are crucial. Low crimp wool provides smoother texture and strength, suitable for fine fabrics, upholstery, and products requiring durability and a sleek finish. Selecting the right wool crimp depends on the end use, balancing factors like softness, elasticity, and durability to enhance product performance.

High Crimp Wool vs Low Crimp Wool Infographic

materialdif.com

materialdif.com