Microcrystalline wax contains smaller, more branched crystals than paraffin wax, resulting in a softer, more flexible texture that enhances stretchability and adhesion in applications like cosmetics and adhesives. Paraffin wax is harder, more brittle, and less flexible, making it ideal for candles, packaging, and sealing where rigidity is required. The higher melting point and finer crystal structure of microcrystalline wax improve moisture resistance and enhanced gloss compared to paraffin wax.

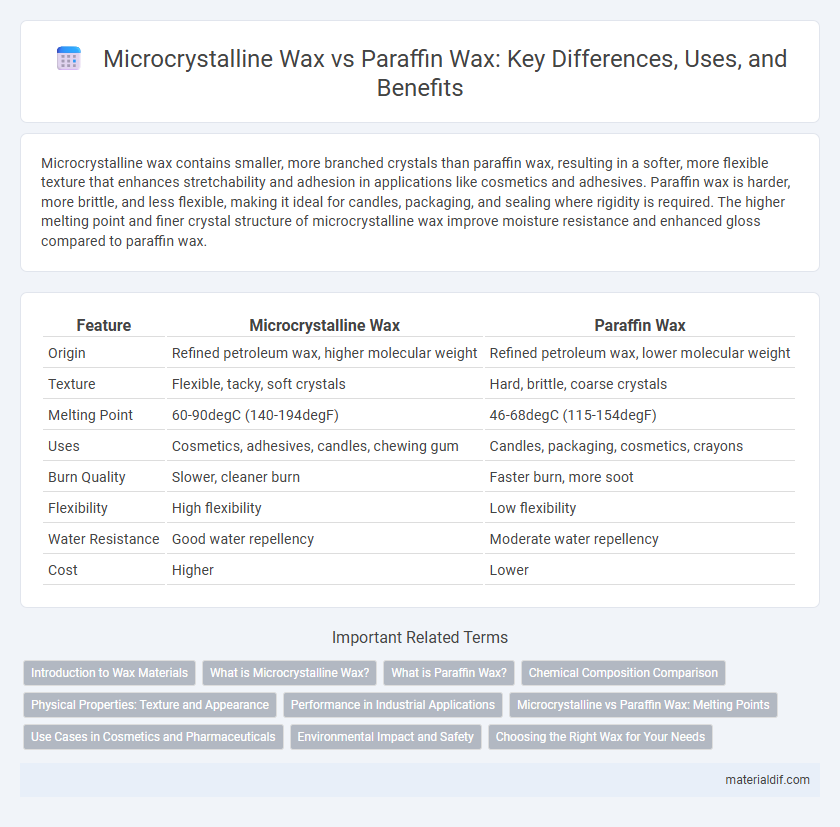

Table of Comparison

| Feature | Microcrystalline Wax | Paraffin Wax |

|---|---|---|

| Origin | Refined petroleum wax, higher molecular weight | Refined petroleum wax, lower molecular weight |

| Texture | Flexible, tacky, soft crystals | Hard, brittle, coarse crystals |

| Melting Point | 60-90degC (140-194degF) | 46-68degC (115-154degF) |

| Uses | Cosmetics, adhesives, candles, chewing gum | Candles, packaging, cosmetics, crayons |

| Burn Quality | Slower, cleaner burn | Faster burn, more soot |

| Flexibility | High flexibility | Low flexibility |

| Water Resistance | Good water repellency | Moderate water repellency |

| Cost | Higher | Lower |

Introduction to Wax Materials

Microcrystalline wax and paraffin wax are derived from petroleum but differ significantly in molecular structure and properties; microcrystalline wax contains smaller, branched crystals, making it more flexible and adhesive, while paraffin wax has larger, linear crystals that provide hardness and brittleness. Microcrystalline wax is commonly used in cosmetics, adhesives, and food coatings due to its pliability and higher melting point, whereas paraffin wax is widely utilized in candle making, packaging, and waterproofing applications. Understanding these fundamental differences is crucial for selecting the appropriate wax material in industrial and commercial production.

What is Microcrystalline Wax?

Microcrystalline wax is a type of wax derived from petroleum, characterized by its fine crystal structure and higher molecular weight compared to paraffin wax. It offers superior flexibility, adhesion, and resistance to cracking, making it ideal for applications such as cosmetics, adhesives, and coatings. The wax's dense composition also provides enhanced moisture retention and a glossy finish, distinguishing it from the more brittle and lower melting point paraffin wax.

What is Paraffin Wax?

Paraffin wax is a white or colorless, odorless solid derived from petroleum refining, primarily composed of saturated hydrocarbons with molecular weights between C20 and C40. It is widely used in industries such as cosmetics, food processing, and candle making due to its smooth texture, low melting point (typically 46-68degC), and excellent moisture barrier properties. Unlike microcrystalline wax, paraffin wax has a more crystalline structure with smaller molecules, resulting in a harder and more brittle consistency.

Chemical Composition Comparison

Microcrystalline wax contains branched and non-linear hydrocarbons with higher molecular weight, resulting in a finer crystal structure and greater flexibility compared to paraffin wax, which is primarily composed of linear alkanes with lower molecular weight. The complex molecular arrangement in microcrystalline wax contributes to its higher melting point and oil retention properties, while paraffin wax exhibits a more uniform and crystalline structure ideal for rigidity and easy melting. Chemical analysis reveals that microcrystalline wax has a broader range of carbon atoms, typically from C30 to C70, whereas paraffin wax ranges mainly from C20 to C40 hydrocarbons.

Physical Properties: Texture and Appearance

Microcrystalline wax exhibits a finer crystal structure with a more flexible, tackier texture and higher melting point compared to paraffin wax, which has a coarser, brittle texture and lower melting point. The appearance of microcrystalline wax is typically translucent and glossy, while paraffin wax appears more opaque and matte. These physical differences influence their suitability for applications requiring pliability or rigidity.

Performance in Industrial Applications

Microcrystalline wax exhibits superior flexibility, higher melting points, and better adhesion compared to paraffin wax, making it ideal for demanding industrial applications such as coatings, adhesives, and rubber compounding. Paraffin wax, with its lower melting point and crystalline structure, is preferred for applications requiring easy melting and molding, like candles and packaging. The enhanced performance of microcrystalline wax in abrasion resistance and moisture barrier properties drives its use in heavy-duty industrial processes.

Microcrystalline vs Paraffin Wax: Melting Points

Microcrystalline wax has a higher melting point, typically ranging from 60degC to 90degC, compared to paraffin wax which melts between 46degC and 68degC. This difference in melting points makes microcrystalline wax more suitable for applications requiring greater heat resistance and flexibility, such as cosmetics and adhesives. The finer crystal structure of microcrystalline wax also contributes to its increased melting point and enhanced durability relative to paraffin wax.

Use Cases in Cosmetics and Pharmaceuticals

Microcrystalline wax, with its finer crystal structure and higher melting point, offers superior flexibility and adhesion in cosmetics, making it ideal for lip balms, creams, and ointments requiring enhanced texture and moisture retention. Paraffin wax, characterized by a coarser crystalline structure and lower melting point, is widely used in pharmaceutical applications such as ointment bases and coating agents due to its excellent barrier properties and cost-effectiveness. Both waxes serve critical roles in formulations, but microcrystalline wax is preferred where elasticity and durability are essential, while paraffin wax is chosen for its ease of formulation and stability in drug delivery systems.

Environmental Impact and Safety

Microcrystalline wax, derived from petroleum refining, has a denser molecular structure contributing to slower biodegradation compared to paraffin wax, which is also petroleum-based but lighter and more prone to environmental persistence. Both waxes pose similar safety concerns related to flammability and exposure risks, but microcrystalline wax typically has a higher flash point, making it slightly safer for industrial handling. Environmental impact assessments highlight that neither wax is biodegradable; however, paraffin wax's widespread use in disposable products leads to greater accumulation in landfills, intensifying ecological challenges.

Choosing the Right Wax for Your Needs

Microcrystalline wax offers a finer crystal structure and greater flexibility compared to paraffin wax, making it ideal for applications requiring superior adhesion, elasticity, and moisture resistance such as cosmetics and skincare products. Paraffin wax, derived from petroleum, features a harder texture and higher melting point, commonly used in candle making, packaging, and coatings due to its cost-effectiveness and ease of use. Selecting the right wax depends on factors like melting point, texture, and application-specific requirements to ensure optimal performance and product quality.

Microcrystalline wax vs Paraffin wax Infographic

materialdif.com

materialdif.com