Natural quartz forms through geological processes over millions of years, exhibiting unique variations in color, clarity, and inclusions that make each piece distinct. Synthetic quartz is created in laboratories using hydrothermal methods, offering high purity and consistent quality ideal for industrial applications. Differences in origin affect durability and cost, with natural quartz prized for aesthetics and synthetic quartz valued for precision and uniformity.

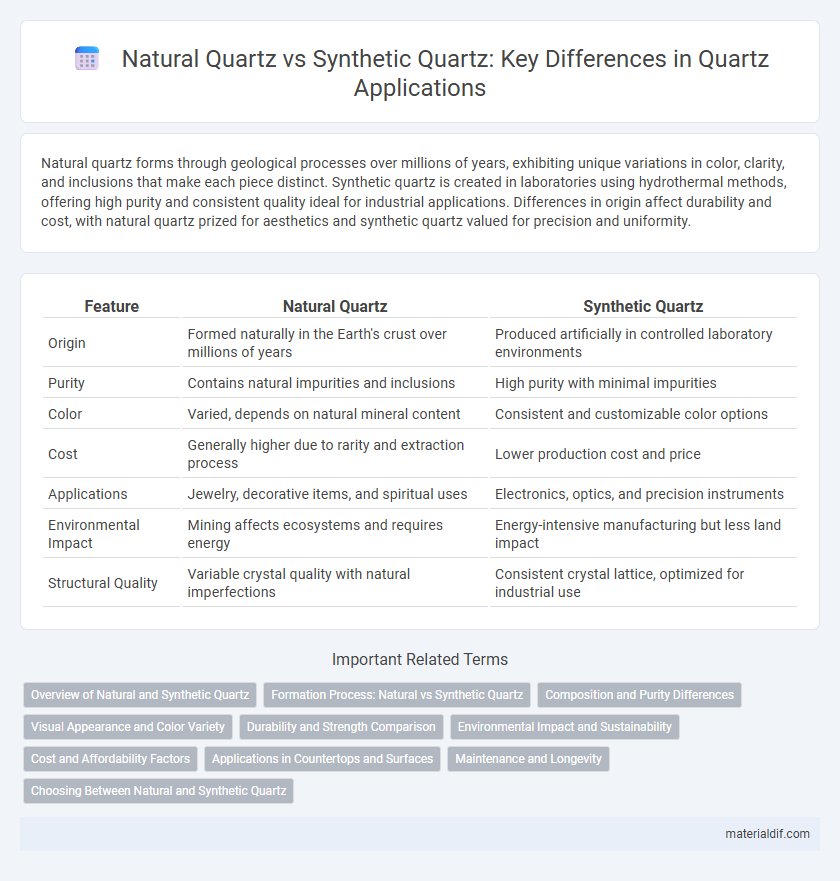

Table of Comparison

| Feature | Natural Quartz | Synthetic Quartz |

|---|---|---|

| Origin | Formed naturally in the Earth's crust over millions of years | Produced artificially in controlled laboratory environments |

| Purity | Contains natural impurities and inclusions | High purity with minimal impurities |

| Color | Varied, depends on natural mineral content | Consistent and customizable color options |

| Cost | Generally higher due to rarity and extraction process | Lower production cost and price |

| Applications | Jewelry, decorative items, and spiritual uses | Electronics, optics, and precision instruments |

| Environmental Impact | Mining affects ecosystems and requires energy | Energy-intensive manufacturing but less land impact |

| Structural Quality | Variable crystal quality with natural imperfections | Consistent crystal lattice, optimized for industrial use |

Overview of Natural and Synthetic Quartz

Natural quartz is a crystalline mineral composed primarily of silicon dioxide, found widely in the Earth's crust with unique impurities giving it distinct colors and properties. Synthetic quartz is artificially grown in controlled environments using hydrothermal processes to produce high-purity crystals with consistent structure and fewer defects. Both types serve vital roles in industries such as electronics, optics, and timekeeping, with synthetic quartz favored for precision applications due to its uniformity.

Formation Process: Natural vs Synthetic Quartz

Natural quartz forms over millions of years through geological processes involving the cooling of magma or hydrothermal activity, resulting in crystal structures rich in trace minerals. Synthetic quartz is created in laboratories using the hydrothermal growth method, where nutrient-rich solutions are subjected to high pressure and temperature to accelerate crystal formation within weeks. The formation process of synthetic quartz allows for controlled purity and uniformity, contrasting with the variable composition of natural quartz.

Composition and Purity Differences

Natural quartz is primarily composed of silicon dioxide (SiO2) with trace impurities like iron, aluminum, and titanium, which affect its coloration and clarity. Synthetic quartz is manufactured through hydrothermal processes, resulting in high-purity crystals with minimal inclusions and controlled elemental composition. This controlled environment allows synthetic quartz to have superior optical clarity and consistent chemical properties compared to natural quartz.

Visual Appearance and Color Variety

Natural quartz exhibits unique inclusions and subtle color variations resulting from trace mineral impurities, giving each piece distinct patterns and hues such as milky white, rose pink, and smoky gray. Synthetic quartz, manufactured under controlled conditions, offers a more uniform clarity and a broader, consistent color range including vivid blues, purples, and greens unavailable in natural quartz. The visual appearance of natural quartz is often irregular and less predictable, while synthetic quartz provides highly consistent aesthetics ideal for precise decorative and industrial applications.

Durability and Strength Comparison

Natural quartz, formed over millions of years through geological processes, exhibits exceptional hardness rating 7 on the Mohs scale, providing strong resistance to scratching and wear. Synthetic quartz, engineered in laboratories by combining silicon dioxide with trace elements, offers comparable durability but can be manufactured to have enhanced consistency and fewer internal flaws. While natural quartz may contain slight inclusions that affect its overall strength, synthetic quartz's uniform structure generally ensures improved toughness and longevity in industrial and decorative applications.

Environmental Impact and Sustainability

Natural quartz extraction involves mining processes that can lead to habitat disruption, soil erosion, and significant energy consumption, contributing to environmental degradation. Synthetic quartz production utilizes controlled laboratory methods, reducing habitat loss and often enabling better resource efficiency, though it still requires substantial energy inputs, mostly from electricity sources that may vary in sustainability. When comparing environmental impacts, synthetic quartz generally offers improved sustainability prospects through minimized land disturbance and the potential for cleaner energy use, making it a more environmentally preferable option in industries prioritizing eco-friendly materials.

Cost and Affordability Factors

Natural quartz typically commands higher prices due to its rarity and the costs associated with mining and processing, making it less affordable for large-scale industrial applications. Synthetic quartz, produced through hydrothermal processes, offers a cost-effective alternative with consistent quality and availability, significantly reducing expenses for electronics and optical industries. The affordability of synthetic quartz enables widespread use in manufacturing while preserving natural quartz for specialized, high-end uses.

Applications in Countertops and Surfaces

Natural quartz offers unique mineral patterns and color variations ideal for luxury countertops, while synthetic quartz provides consistent aesthetics and enhanced durability through engineered resin bonding. Synthetic quartz surfaces resist staining, scratching, and heat better than natural quartz, making them preferable for high-traffic kitchen and commercial applications. The customizable nature of synthetic quartz allows for a broader range of colors and finishes, meeting diverse design specifications in residential and commercial interiors.

Maintenance and Longevity

Natural quartz exhibits exceptional durability and requires minimal maintenance due to its inherent hardness and resistance to scratches and heat. Synthetic quartz, engineered with resins, offers enhanced consistency but may be more susceptible to heat damage and discoloration over time, necessitating careful upkeep. Both types provide long-lasting performance, but natural quartz generally outperforms synthetic variants in terms of longevity and wear resistance.

Choosing Between Natural and Synthetic Quartz

Natural quartz offers unique, irregular crystal formations prized for their authenticity and mineral inclusions, while synthetic quartz provides consistent purity and precise chemical composition ideal for industrial applications. Choosing between natural and synthetic quartz depends on factors such as budget, intended use, and the importance of geological origin or material uniformity. For decorative or metaphysical use, natural quartz's distinct patterns enhance aesthetic value, whereas synthetic quartz delivers superior performance in electronic devices due to its controlled properties.

Natural Quartz vs Synthetic Quartz Infographic

materialdif.com

materialdif.com