Spider silk is renowned for its superior tensile strength and elasticity compared to Bombyx mori silk, making it one of the toughest natural fibers known. Bombyx mori silk, produced by domesticated silkworms, is prized for its smooth texture and ease of harvesting, contributing to its widespread use in textiles. Advances in biotechnology aim to combine the strength of spider silk with the commercial viability of Bombyx mori silk to develop innovative materials with enhanced durability and flexibility.

Table of Comparison

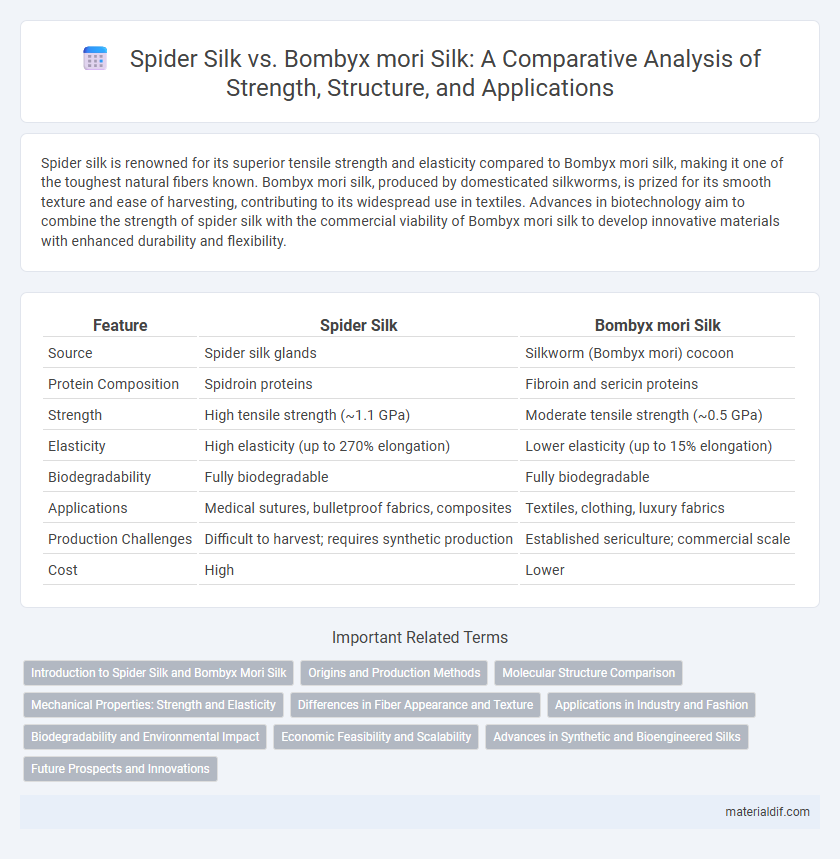

| Feature | Spider Silk | Bombyx mori Silk |

|---|---|---|

| Source | Spider silk glands | Silkworm (Bombyx mori) cocoon |

| Protein Composition | Spidroin proteins | Fibroin and sericin proteins |

| Strength | High tensile strength (~1.1 GPa) | Moderate tensile strength (~0.5 GPa) |

| Elasticity | High elasticity (up to 270% elongation) | Lower elasticity (up to 15% elongation) |

| Biodegradability | Fully biodegradable | Fully biodegradable |

| Applications | Medical sutures, bulletproof fabrics, composites | Textiles, clothing, luxury fabrics |

| Production Challenges | Difficult to harvest; requires synthetic production | Established sericulture; commercial scale |

| Cost | High | Lower |

Introduction to Spider Silk and Bombyx Mori Silk

Spider silk, produced by orb-weaving spiders, exhibits remarkable tensile strength and elasticity, making it one of the toughest natural fibers known. Bombyx mori silk, derived from the domesticated silkworm, is widely valued for its smooth texture and commercial availability in textile manufacturing. Both types of silk offer unique biochemical compositions and mechanical properties, positioning them as promising materials for biomedical and industrial applications.

Origins and Production Methods

Spider silk originates from orb-weaving spiders like Nephila, produced through specialized abdominal glands that spin proteins into strong, flexible fibers via natural extrusion. Bombyx mori silk, derived from domesticated silkworms cultivated in sericulture farms, is harvested by boiling cocoons to extract continuous fibroin filaments. Unlike the spider's solitary silk production, Bombyx mori silk production relies on controlled larval cultivation, enabling large-scale, consistent fiber yield.

Molecular Structure Comparison

Spider silk exhibits a unique molecular structure characterized by repetitive protein sequences rich in glycine and alanine, forming highly organized b-sheet nanocrystals that impart exceptional tensile strength and elasticity. In contrast, Bombyx mori silk primarily consists of fibroin proteins with a predominance of alanine and glycine but arranged in less repetitive structures, resulting in a more crystalline but less elastic fiber. The molecular alignment and hydrogen bonding patterns differ significantly between the two, with spider silk demonstrating superior toughness due to its hierarchical nanostructure and dynamic protein folding.

Mechanical Properties: Strength and Elasticity

Spider silk exhibits superior mechanical properties compared to Bombyx mori silk, boasting tensile strength up to 1.3 GPa, surpassing many synthetic fibers. Its remarkable elasticity allows it to stretch up to 30% of its original length without breaking, providing a unique combination of toughness and flexibility. In contrast, Bombyx mori silk typically reaches tensile strengths around 0.6 GPa with lower extensibility, making spider silk highly sought after for advanced material applications.

Differences in Fiber Appearance and Texture

Spider silk fibers exhibit a finer, glossier appearance with a natural shimmer and a more irregular, crimped texture compared to Bombyx mori silk, which is smoother, more uniform, and matte. The diameter of spider silk is generally thinner, contributing to its exceptional tensile strength and elasticity, while Bombyx mori silk fibers are thicker and softer to the touch. Spider silk's irregular surface enhances its adhesive properties, whereas Bombyx mori silk's consistent texture favors dye uptake and fabric finishing processes.

Applications in Industry and Fashion

Spider silk offers superior tensile strength and elasticity compared to Bombyx mori silk, making it ideal for high-performance applications such as biodegradable medical sutures and advanced protective textiles. Bombyx mori silk remains dominant in the fashion industry due to its availability, luster, and ease of dyeing, supporting luxury apparel and home furnishings. Innovations combining spider silk proteins with Bombyx mori silk aim to enhance fabric durability and sustainability, opening new possibilities for eco-friendly, high-value textile products.

Biodegradability and Environmental Impact

Spider silk exhibits superior biodegradability compared to Bombyx mori silk due to its natural protein composition, which breaks down more efficiently in soil and aquatic environments. Bombyx mori silk, while biodegradable, often requires chemical treatments during processing that can introduce pollutants and hinder its eco-friendliness. The overall environmental impact of spider silk is lower, as its production does not depend on sericulture or the extensive use of pesticides and water resources common in Bombyx mori silk farming.

Economic Feasibility and Scalability

Spider silk offers exceptional mechanical properties and biodegradability, but its economic feasibility is limited by low natural yield and challenges in large-scale farming. Bombyx mori silk, cultivated through well-established sericulture practices, provides scalable production with consistent quality and lower cost, supporting its dominant position in the textile industry. Advances in recombinant technology aim to enhance spider silk scalability, yet Bombyx mori silk remains more economically viable for mass-market applications.

Advances in Synthetic and Bioengineered Silks

Spider silk exhibits exceptional tensile strength and elasticity compared to Bombyx mori silk, driving advances in synthetic and bioengineered silk production. Recent breakthroughs utilize recombinant DNA technology and protein engineering to replicate spider silk proteins, enabling scalable manufacturing with customizable properties. These innovations hold promise for diverse applications, including biomedical materials, textiles, and environmentally sustainable alternatives to traditional silk.

Future Prospects and Innovations

Spider silk exhibits exceptional tensile strength, elasticity, and biocompatibility, making it a prime candidate for future biomedical applications and high-performance textiles. Innovations in genetic engineering and synthetic biology are advancing the production of spider silk proteins in microorganisms and plants, overcoming the scalability limitations faced by Bombyx mori silk. Bombyx mori silk remains vital for its established commercial cultivation, but emerging hybrid materials combining spider silk's mechanical properties with silkworm silk's ease of production highlight promising avenues for sustainable and high-strength textile development.

Spider silk vs Bombyx mori silk Infographic

materialdif.com

materialdif.com