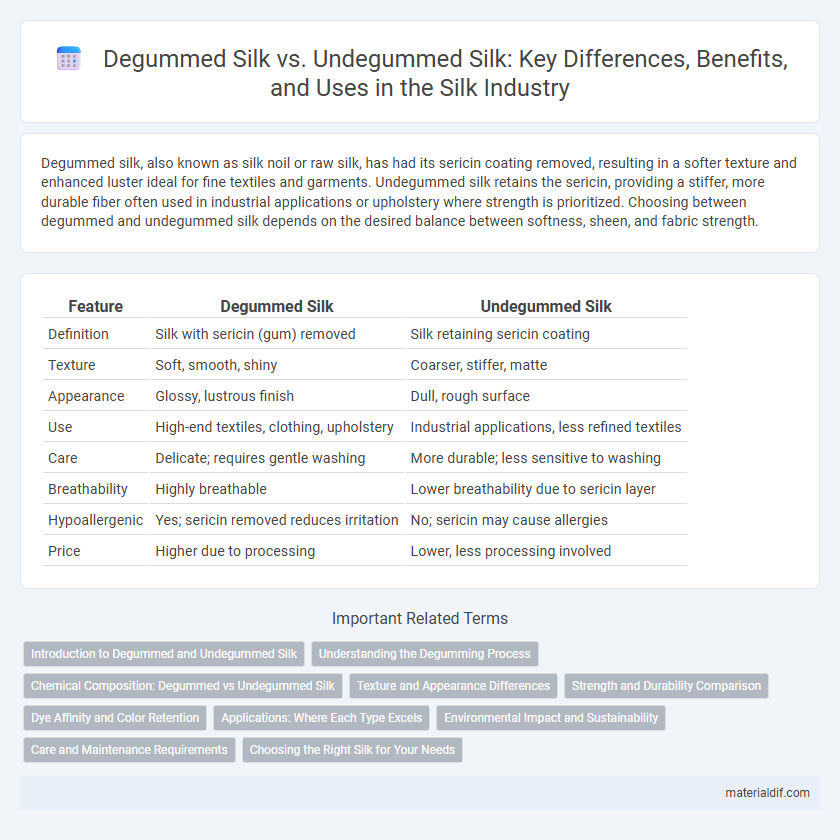

Degummed silk, also known as silk noil or raw silk, has had its sericin coating removed, resulting in a softer texture and enhanced luster ideal for fine textiles and garments. Undegummed silk retains the sericin, providing a stiffer, more durable fiber often used in industrial applications or upholstery where strength is prioritized. Choosing between degummed and undegummed silk depends on the desired balance between softness, sheen, and fabric strength.

Table of Comparison

| Feature | Degummed Silk | Undegummed Silk |

|---|---|---|

| Definition | Silk with sericin (gum) removed | Silk retaining sericin coating |

| Texture | Soft, smooth, shiny | Coarser, stiffer, matte |

| Appearance | Glossy, lustrous finish | Dull, rough surface |

| Use | High-end textiles, clothing, upholstery | Industrial applications, less refined textiles |

| Care | Delicate; requires gentle washing | More durable; less sensitive to washing |

| Breathability | Highly breathable | Lower breathability due to sericin layer |

| Hypoallergenic | Yes; sericin removed reduces irritation | No; sericin may cause allergies |

| Price | Higher due to processing | Lower, less processing involved |

Introduction to Degummed and Undegummed Silk

Degummed silk refers to silk fibers that have undergone a process to remove sericin, the natural gum coating, resulting in a softer, smoother texture and enhanced luster ideal for high-quality textiles. Undegummed silk retains this sericin layer, offering a stiffer, slightly rougher feel, often used in raw or traditional silk products. Understanding the distinction between degummed and undegummed silk is essential for selecting the right material based on desired softness, sheen, and application in silk-based apparel or home furnishings.

Understanding the Degumming Process

Degummed silk undergoes a precise process that removes sericin, the gummy protein coating the natural silk fibers, resulting in a softer, more lustrous fabric favored in luxury textiles. Undegummed silk retains this sericin layer, making it stiffer, rougher, and less absorbent, often used in industrial applications or for specific traditional crafts. The degumming process typically involves boiling silk in a mild alkaline solution, such as soap or soda ash, which dissolves sericin without damaging the fibroin fibers, enhancing silk's tensile strength and dye affinity.

Chemical Composition: Degummed vs Undegummed Silk

Degummed silk, also known as pure silk, consists primarily of fibroin protein, as the sericin gum is removed through chemical processes, resulting in a smoother and softer texture. Undegummed silk retains sericin, a gummy protein that coats fibroin fibers, giving it a rougher feel and increased stiffness. The chemical composition difference between degummed and undegummed silk significantly influences properties such as dye uptake, moisture absorption, and tensile strength.

Texture and Appearance Differences

Degummed silk has a smooth, soft texture with a glossy, lustrous appearance due to the removal of sericin, which enhances its sheen and flexibility. Undegummed silk retains a rougher, stiffer texture and a matte finish because the sericin layer remains intact, providing a natural protective coating. The texture contrast is significant, with degummed silk favored for delicate garments and upholstery, while undegummed silk is used where durability and a more raw aesthetic are desired.

Strength and Durability Comparison

Degummed silk, having undergone the sericin removal process, demonstrates enhanced strength and durability compared to undegummed silk, as the exposed fibroin fibers create a smoother, more resilient texture. Undegummed silk retains the sericin coating, which makes the fabric stiffer but more prone to abrasion and less flexible under stress. This fundamental difference in fiber composition directly influences the longevity and wear resistance of silk textiles in various applications.

Dye Affinity and Color Retention

Degummed silk, having its natural sericin layer removed, exhibits enhanced dye affinity and superior color retention due to increased fiber absorbency. Undegummed silk retains sericin, which creates a barrier that reduces dye uptake and results in less vibrant and less durable coloration. Therefore, degummed silk is preferred for achieving deep, long-lasting colors in textile applications.

Applications: Where Each Type Excels

Degummed silk, stripped of sericin, excels in textile and fashion industries due to its soft texture and vibrant dye absorption, making it ideal for high-quality garments and luxury fabrics. Undegummed silk, retaining the sericin coating, is preferred in biomedical applications and cosmetics for its natural antimicrobial properties and skin-friendly effects. The distinct chemical composition of each type determines their suitability, with degummed silk favored for comfort and aesthetics, while undegummed silk is valued for functional and therapeutic uses.

Environmental Impact and Sustainability

Degummed silk, produced by removing sericin, reduces environmental pollution during processing compared to undegummed silk, which retains sericin but requires more resource-intensive treatments for textile use. The degumming process allows for better biodegradability and less chemical waste, enhancing the sustainability profile of silk products. Conversely, undegummed silk, while utilizing the natural protective sericin layer, often demands additional chemical treatments that increase environmental footprint and water consumption.

Care and Maintenance Requirements

Degummed silk, also known as silk noil, requires gentle hand washing with mild detergent to preserve its smooth texture and natural sheen. Undegummed silk retains sericin, making it stiffer and less breathable, which demands careful air drying away from direct sunlight to prevent stiffness and discoloration. Proper storage in a cool, dry place with minimal exposure to humidity is essential for both types to maintain fabric integrity and longevity.

Choosing the Right Silk for Your Needs

Degummed silk, also known as spun silk, has had its sericin removed, resulting in a softer texture and enhanced breathability, making it ideal for clothing and delicate textiles. Undegummed silk retains the natural sericin coating, providing greater stiffness and durability preferred in upholstery and industrial applications. Selecting between degummed and undegummed silk depends on whether softness or structural strength is a priority for your specific use.

Degummed silk vs Undegummed silk Infographic

materialdif.com

materialdif.com