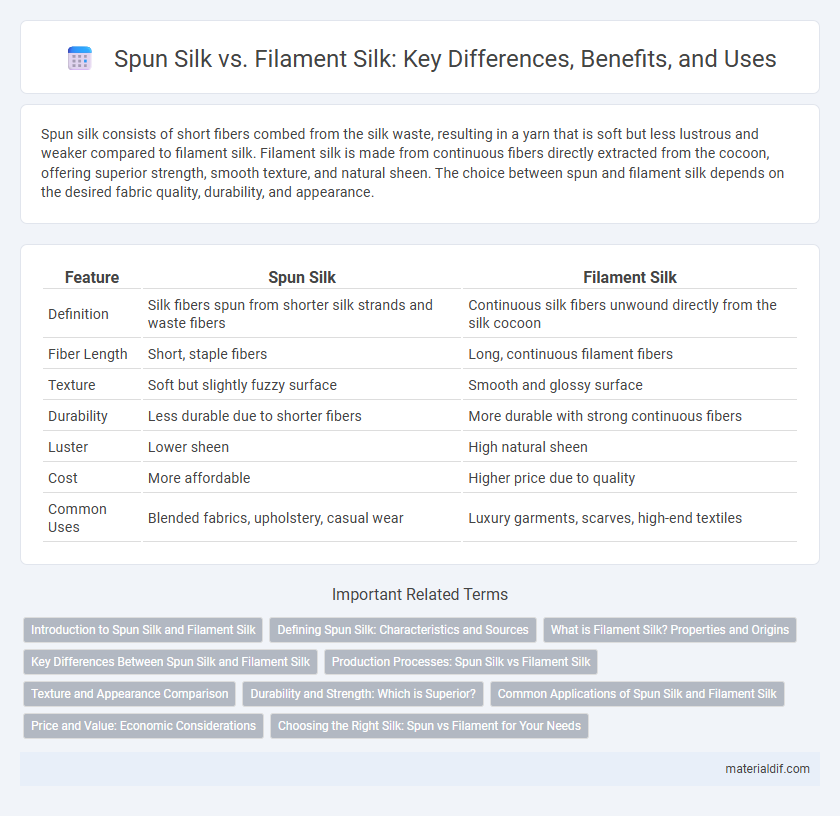

Spun silk consists of short fibers combed from the silk waste, resulting in a yarn that is soft but less lustrous and weaker compared to filament silk. Filament silk is made from continuous fibers directly extracted from the cocoon, offering superior strength, smooth texture, and natural sheen. The choice between spun and filament silk depends on the desired fabric quality, durability, and appearance.

Table of Comparison

| Feature | Spun Silk | Filament Silk |

|---|---|---|

| Definition | Silk fibers spun from shorter silk strands and waste fibers | Continuous silk fibers unwound directly from the silk cocoon |

| Fiber Length | Short, staple fibers | Long, continuous filament fibers |

| Texture | Soft but slightly fuzzy surface | Smooth and glossy surface |

| Durability | Less durable due to shorter fibers | More durable with strong continuous fibers |

| Luster | Lower sheen | High natural sheen |

| Cost | More affordable | Higher price due to quality |

| Common Uses | Blended fabrics, upholstery, casual wear | Luxury garments, scarves, high-end textiles |

Introduction to Spun Silk and Filament Silk

Spun silk is made from shorter silk fibers that are spun together to create a yarn, offering a textured, matte finish often used in less formal textiles. Filament silk consists of long, continuous fibers extracted directly from the silk cocoon, resulting in a smoother, lustrous fabric prized in high-end garments and luxury textiles. The distinction between spun and filament silk lies in fiber length and texture, influencing their applications and fabric quality.

Defining Spun Silk: Characteristics and Sources

Spun silk consists of shorter silk fibers that are carded and spun into yarn, resulting in a slightly coarse texture and a matte finish compared to filament silk. It is primarily sourced from poorer quality or damaged silk cocoons, where continuous filaments are unavailable, making it more affordable and durable. Spun silk's unique fiber structure gives it a soft feel and a warm drape, distinguishing it from the smooth, lustrous appearance of filament silk.

What is Filament Silk? Properties and Origins

Filament silk consists of long, continuous fibers produced by silkworms, typically harvested from the cocoon in a single strand that can measure up to several hundred meters. Known for its smooth texture, high tensile strength, natural sheen, and durability, filament silk is primarily sourced from the Bombyx mori silkworm native to China and India. This type of silk offers superior luster and softness compared to spun silk, which is made from shorter fibers twisted together.

Key Differences Between Spun Silk and Filament Silk

Spun silk consists of staple fibers that are short and twisted together, resulting in a fabric with a matte finish and a slightly rough texture, while filament silk is made from long continuous fibers, producing a smooth, shiny, and luxurious fabric. Filament silk offers higher tensile strength and durability compared to spun silk, which is softer and more affordable due to its shorter fiber length. The manufacturing processes differ as well, with filament silk requiring precise reeling from silkworm cocoons, whereas spun silk involves spinning leftover fibers unsuitable for filament production.

Production Processes: Spun Silk vs Filament Silk

Spun silk is produced by spinning short silk fibers, often from damaged or less perfect cocoons, into yarn, resulting in a textured and matte finish suitable for heavier fabrics. Filament silk involves reeling whole, continuous silk threads directly from intact cocoons, yielding smooth, lustrous, and strong fibers favored in fine silk textiles. The production process of filament silk requires meticulous handling and preservation of cocoon integrity, whereas spun silk utilizes shorter fibers, allowing for more efficient use of raw silk waste.

Texture and Appearance Comparison

Spun silk features a soft, fuzzy texture due to short fibers twisted together, resulting in a matte appearance with subtle irregularities. Filament silk is made from long continuous fibers, providing a smooth, lustrous surface with a consistent sheen. The finer, uniform structure of filament silk enhances its elegant look, while spun silk offers a more textured, cozy feel.

Durability and Strength: Which is Superior?

Spun silk, made from shorter silk fibers, offers moderate durability but lacks the tensile strength of filament silk, which is composed of long, continuous silk fibers. Filament silk exhibits superior strength due to its uninterrupted fiber structure, making it more resilient and long-lasting in textiles. The inherent durability of filament silk surpasses spun silk, making it the preferred choice for high-quality, durable fabric production.

Common Applications of Spun Silk and Filament Silk

Spun silk is commonly used in products like upholstery, textiles, and embroidery due to its soft texture and matte finish, making it ideal for casual and durable applications. Filament silk, prized for its smooth, lustrous surface and strength, is frequently employed in high-end fashion, luxury bedding, and fine scarves where a glossy, refined appearance is desired. Both types of silk serve distinct roles in the textile industry, balancing comfort and aesthetics based on their unique fiber properties.

Price and Value: Economic Considerations

Spun silk is generally more affordable due to its production from shorter fibers and labor-intensive spinning, offering good value for budget-conscious consumers seeking natural silk feel. Filament silk, made from long continuous fibers harvested directly from the cocoon, commands a higher price reflecting superior strength, smoothness, and luster, making it a premium choice for luxury textiles. Economic considerations highlight that while spun silk provides cost-effective charm, filament silk delivers lasting durability and elegance that justify the investment in high-end silk products.

Choosing the Right Silk: Spun vs Filament for Your Needs

Spun silk is made from shorter fibers that are carded and spun into yarn, offering a soft texture and matte finish ideal for casual wear and home textiles. Filament silk consists of long, continuous fibers drawn directly from the cocoon, providing a smooth, lustrous surface perfect for luxury garments and formal attire. Choosing between spun and filament silk depends on durability, sheen preference, and specific application, with filament silk excelling in elegance and spun silk offering comfort and affordability.

Spun silk vs Filament silk Infographic

materialdif.com

materialdif.com