Sericulture involves the traditional cultivation of silkworms to produce natural silk fibers, which is labor-intensive and dependent on mulberry cultivation. Recombinant silk production uses genetic engineering to produce silk proteins in microorganisms or plants, offering scalability and environmental sustainability. This biotechnological approach enables customization of silk properties and reduces reliance on animal farming.

Table of Comparison

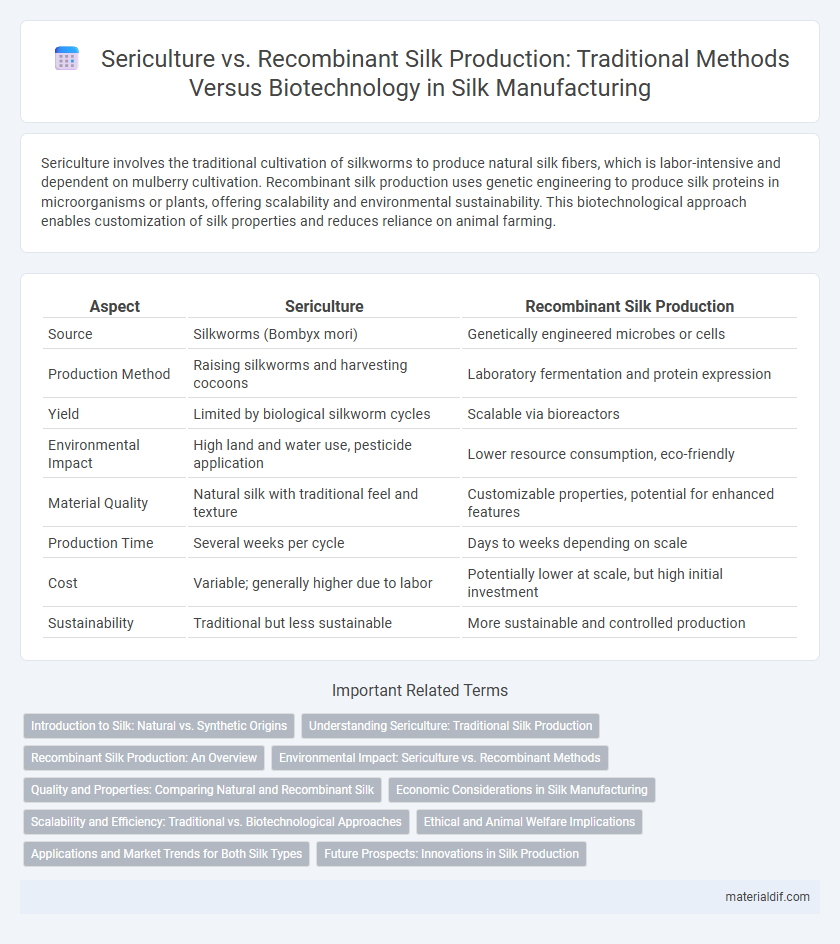

| Aspect | Sericulture | Recombinant Silk Production |

|---|---|---|

| Source | Silkworms (Bombyx mori) | Genetically engineered microbes or cells |

| Production Method | Raising silkworms and harvesting cocoons | Laboratory fermentation and protein expression |

| Yield | Limited by biological silkworm cycles | Scalable via bioreactors |

| Environmental Impact | High land and water use, pesticide application | Lower resource consumption, eco-friendly |

| Material Quality | Natural silk with traditional feel and texture | Customizable properties, potential for enhanced features |

| Production Time | Several weeks per cycle | Days to weeks depending on scale |

| Cost | Variable; generally higher due to labor | Potentially lower at scale, but high initial investment |

| Sustainability | Traditional but less sustainable | More sustainable and controlled production |

Introduction to Silk: Natural vs. Synthetic Origins

Sericulture, the traditional method of silk production, involves cultivating silkworms that spin natural protein fibers, offering a sustainable and biodegradable textile source. Recombinant silk production utilizes genetic engineering techniques to produce silk proteins in host organisms like bacteria or yeast, allowing scalable and customizable fiber synthesis. Both approaches yield versatile materials but differ fundamentally in origin, environmental impact, and potential for innovation in textile engineering.

Understanding Sericulture: Traditional Silk Production

Sericulture involves the cultivation of silkworms, primarily Bombyx mori, to produce natural silk fibers through their cocoons, a process rooted in ancient agricultural practices. This traditional silk production hinges on meticulous care of mulberry trees, silkworm rearing, and harvesting cocoons for extraction of fibroin and sericin proteins that form the silk fiber. Understanding sericulture is crucial for appreciating the natural origin, environmental impact, and quality characteristics that differentiate it from recombinant silk production techniques.

Recombinant Silk Production: An Overview

Recombinant silk production leverages genetic engineering to produce silk proteins in host organisms such as bacteria, yeast, or plants, offering a sustainable alternative to traditional sericulture. This method enables precise control over silk protein composition, enhancing properties like strength, elasticity, and biocompatibility for advanced biomedical and textile applications. Scalability and reduced dependency on silkworm farming make recombinant silk a promising innovation in the silk industry.

Environmental Impact: Sericulture vs. Recombinant Methods

Sericulture relies on mulberry cultivation and silkworm rearing, generating significant water use and pesticide application that impact soil and biodiversity. Recombinant silk production utilizes genetically engineered microorganisms in controlled bioreactors, drastically reducing land use, water consumption, and chemical inputs compared to traditional sericulture. This biotechnological approach offers a scalable, eco-friendly alternative that minimizes environmental degradation and supports sustainable silk manufacturing.

Quality and Properties: Comparing Natural and Recombinant Silk

Natural sericulture silk exhibits superior tensile strength, elasticity, and biocompatibility due to its complex protein structure and natural fibroin composition. Recombinant silk, produced through genetic engineering in host organisms, allows for customization of silk properties such as enhanced durability and specific molecular traits but often lacks the uniform fiber morphology found in traditional silk. Quality differences impact applications, with sericulture silk favored in luxury textiles and recombinant silk gaining attention in biomedical and industrial fields for its tailored functionality.

Economic Considerations in Silk Manufacturing

Sericulture, relying on traditional mulberry cultivation and silkworm rearing, involves high labor costs and seasonal variability, impacting production consistency and scalability. Recombinant silk production offers economic advantages by enabling large-scale, controlled synthesis of silk proteins through microbial fermentation, reducing dependency on agricultural factors and lowering overall production costs. Investments in biotechnology infrastructure and raw materials for recombinant methods may be higher initially but provide improved profitability and market stability over time.

Scalability and Efficiency: Traditional vs. Biotechnological Approaches

Sericulture relies on cultivating silkworms to produce silk fibers, which limits scalability due to dependency on mulberry leaves and climatic conditions, resulting in lower production efficiency. Recombinant silk production employs genetically engineered microorganisms or cells to synthesize silk proteins, offering enhanced scalability and faster production cycles under controlled bioreactor conditions. This biotechnological approach enables consistent quality and higher yield, surpassing traditional sericulture in industrial silk manufacturing potential.

Ethical and Animal Welfare Implications

Sericulture involves harvesting silk from silkworms, often resulting in the death of the larvae, raising significant animal welfare concerns. Recombinant silk production utilizes genetically engineered organisms to produce silk proteins without harming animals, offering a cruelty-free alternative. This method addresses ethical issues by eliminating the need for silkworm cultivation and harvesting, promoting sustainable and animal-friendly textile development.

Applications and Market Trends for Both Silk Types

Sericulture-produced silk, renowned for its natural luster and strength, dominates luxury textiles, fashion, and traditional crafts, while recombinant silk, engineered through genetic modification, expands applications into biomedical devices, drug delivery systems, and environmental sensors due to its customizable properties. Market trends reveal increasing investment in recombinant silk for sustainable manufacturing and innovative materials, driven by demand for biodegradable and high-performance fibers in aerospace and medical industries. Both silk types benefit from growing consumer interest in eco-friendly products, but recombinant silk's scalability and functional versatility position it as a disruptive force in advanced material markets.

Future Prospects: Innovations in Silk Production

Future prospects in silk production emphasize innovations in both sericulture and recombinant silk methods. Advancements in genetic engineering enable recombinant silk to mimic the strength and elasticity of natural silk, potentially revolutionizing textile manufacturing with sustainable and customizable materials. Enhanced sericulture techniques, including selective breeding and precision farming, aim to improve yield and quality, supporting eco-friendly production to meet increasing global demand.

Sericulture vs Recombinant silk production Infographic

materialdif.com

materialdif.com