Raw silk retains its natural sericin coating, making it stronger, more lustrous, and slightly rougher to the touch compared to spun silk, which is made by spinning shorter fibers together after removing the sericin. Spun silk has a softer texture and is more affordable, but it lacks the durability and sheen of raw silk. Choosing between raw silk and spun silk depends on the desired balance between texture, strength, and cost for fabrics or garments.

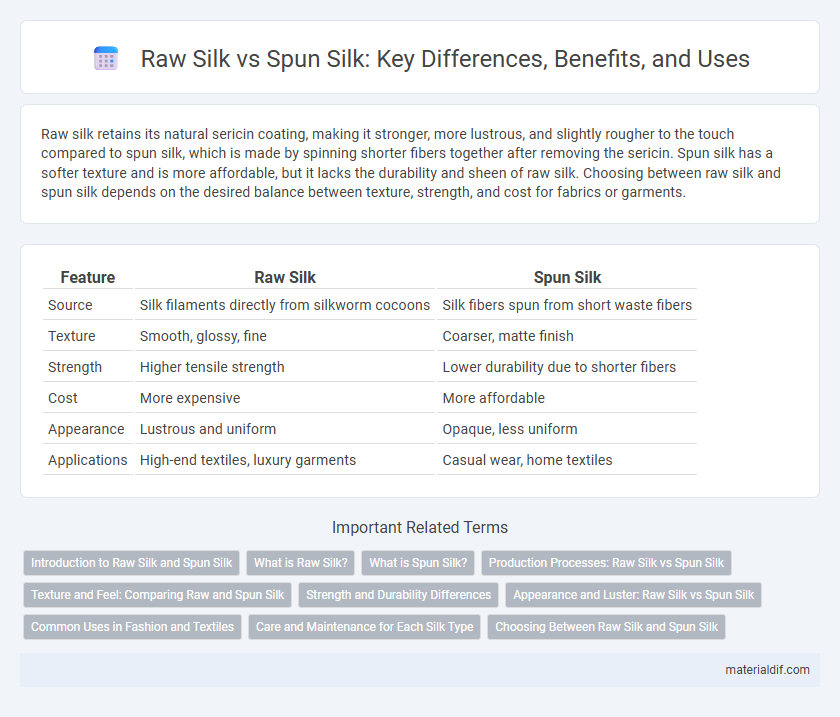

Table of Comparison

| Feature | Raw Silk | Spun Silk |

|---|---|---|

| Source | Silk filaments directly from silkworm cocoons | Silk fibers spun from short waste fibers |

| Texture | Smooth, glossy, fine | Coarser, matte finish |

| Strength | Higher tensile strength | Lower durability due to shorter fibers |

| Cost | More expensive | More affordable |

| Appearance | Lustrous and uniform | Opaque, less uniform |

| Applications | High-end textiles, luxury garments | Casual wear, home textiles |

Introduction to Raw Silk and Spun Silk

Raw silk refers to silk fibers that are harvested directly from silkworm cocoons without significant processing, retaining sericin, the natural gum that provides a slightly rough texture and stronger durability. Spun silk, however, consists of shorter silk fibers that are brushed out from the leftover silk waste after reeling, resulting in a softer, matte finish with lower tensile strength compared to raw silk. Understanding the differences between raw silk and spun silk is crucial for applications in textiles, where texture, strength, and sheen are key factors.

What is Raw Silk?

Raw silk is the natural fiber obtained directly from silk cocoons without removing the sericin, the gummy substance that binds the silk threads together. It retains a coarser texture, richer luster, and greater strength compared to spun silk, which is made from shorter fibers or floss spun together. The presence of sericin in raw silk enhances its durability and gives it a unique tactile quality favored in luxury textiles and traditional garments.

What is Spun Silk?

Spun silk is made from shorter silk fibers that are broken or damaged during the silk reeling process, resulting in a yarn that is spun rather than reeled. Unlike raw silk, which retains the natural gum sericin coating, spun silk undergoes degumming to remove sericin, giving it a softer and more matte finish. This type of silk is more affordable, durable, and has a slightly coarser texture compared to the smoothness and sheen of raw silk.

Production Processes: Raw Silk vs Spun Silk

Raw silk is produced by carefully unwinding the outer filament of the silk cocoon, preserving the sericin gum which gives it a glossy and smooth texture. Spun silk is made by crushing the cocoons and spinning the short fibers extracted from the inner part, resulting in a fabric with a matte finish and a softer hand feel. The production process of raw silk requires delicate handling to maintain filament length, while spun silk involves mechanical processing that shortens fibers and alters fabric strength and appearance.

Texture and Feel: Comparing Raw and Spun Silk

Raw silk features a textured surface with a natural sheen and slight irregularities, offering a crisp, slightly coarse feel that enhances its organic appeal. Spun silk, made from short silk fibers, produces a smoother, matte finish with a soft, cotton-like texture that feels more uniform and less lustrous. The choice between raw and spun silk depends on the desired tactile experience, with raw silk providing a rustic, tactile depth and spun silk delivering a gentle, casual softness.

Strength and Durability Differences

Raw silk maintains the sericin coating, resulting in higher tensile strength and greater durability compared to spun silk, which is made from shorter, broken fibers. Spun silk's weaker fiber bonds lead to less resistance to abrasion and reduced longevity in fabric use. The intact filaments in raw silk contribute to its superior strength, making it more suitable for high-stress applications like upholstery and heavy garments.

Appearance and Luster: Raw Silk vs Spun Silk

Raw silk exhibits a rougher texture with natural sericin coating that gives it a matte, rustic appearance and a subtle, uneven luster. Spun silk, made from shorter silk fibers, appears softer and less shiny due to the absence of sericin and more twisted yarn structure. The higher sheen and smoothness of raw silk distinguish it from the muted, duller surface typical of spun silk fabrics.

Common Uses in Fashion and Textiles

Raw silk is prized in fashion for its natural luster and texture, commonly used in luxury garments like evening wear and bridal dresses. Spun silk, created from shorter fibers, offers a matte finish and is widely utilized in everyday textiles such as scarves, shirts, and casual apparel. Both types of silk serve distinct roles, with raw silk emphasizing elegance and spun silk providing versatility in fabric applications.

Care and Maintenance for Each Silk Type

Raw silk requires gentle care, including hand washing in cold water with mild detergent to preserve its natural sericin coating and texture. Spun silk, made from shorter fibers, is more durable but benefits from delicate washing cycles or dry cleaning to maintain its softness and sheen. Both types should be air-dried away from direct sunlight and ironed on low heat with a cloth between the fabric and iron to prevent damage.

Choosing Between Raw Silk and Spun Silk

Raw silk retains the sericin gum, giving it a coarse texture and natural luster ideal for durable fabrics and traditional garments. Spun silk, made from short fibers without sericin, offers a softer, matte finish better suited for lightweight, breathable clothing and delicate accessories. Selection between raw and spun silk depends on the desired texture, strength, and application in fashion or home textiles.

Raw silk vs Spun silk Infographic

materialdif.com

materialdif.com