Silk noil is made from shorter silk fibers left over after the reeled filament silk is produced, resulting in a textured and matte fabric with a slightly nubby feel. Spun silk, on the other hand, is created by twisting these shorter fibers into yarn, producing a softer and more durable fabric with a subtle sheen similar to reeled silk. Both types offer unique qualities, with silk noil favored for its organic, rustic appearance and spun silk appreciated for its smoothness and strength.

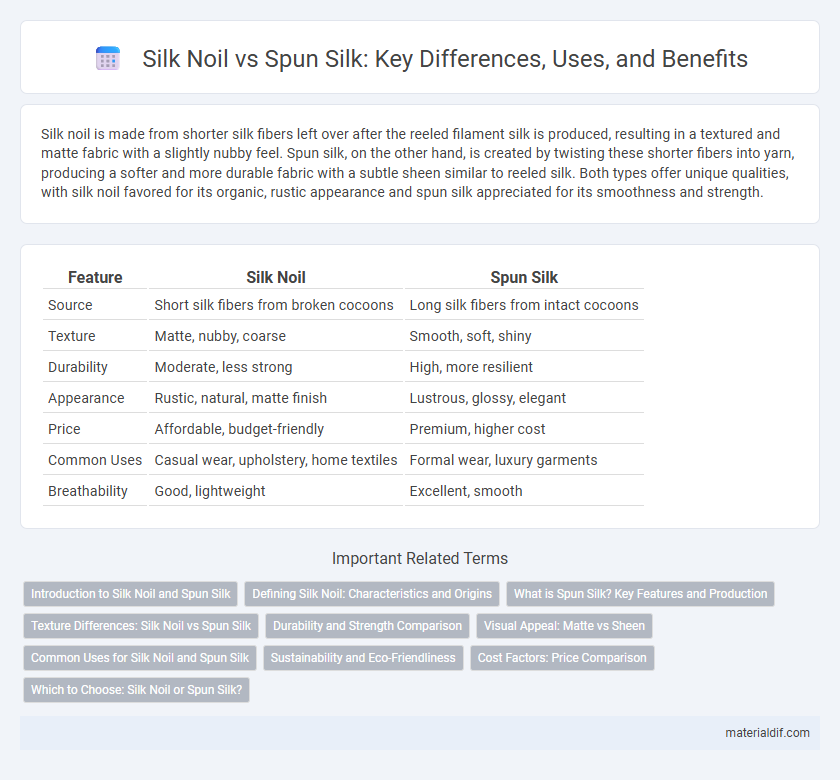

Table of Comparison

| Feature | Silk Noil | Spun Silk |

|---|---|---|

| Source | Short silk fibers from broken cocoons | Long silk fibers from intact cocoons |

| Texture | Matte, nubby, coarse | Smooth, soft, shiny |

| Durability | Moderate, less strong | High, more resilient |

| Appearance | Rustic, natural, matte finish | Lustrous, glossy, elegant |

| Price | Affordable, budget-friendly | Premium, higher cost |

| Common Uses | Casual wear, upholstery, home textiles | Formal wear, luxury garments |

| Breathability | Good, lightweight | Excellent, smooth |

Introduction to Silk Noil and Spun Silk

Silk noil, also known as raw silk, is made from short fibers leftover during silk processing, giving it a textured and matte finish that is breathable and durable. Spun silk is created by spinning these shorter fibers into yarn, resulting in a fabric that balances lustrous softness with strength, often used for affordable yet elegant textiles. Both silk noil and spun silk showcase unique qualities compared to traditional filament silk, offering versatile options for fashion and home decor.

Defining Silk Noil: Characteristics and Origins

Silk noil, also known as silk waste, is derived from the shorter fibers left over after the long, smooth filaments are spun into traditional silk threads. Characterized by its matte finish, nubby texture, and increased durability, silk noil offers a distinct, rustic appearance compared to the lustrous surface of spun silk. Originating primarily from the silk reeling and spinning process, silk noil represents an eco-friendly, sustainable alternative that utilizes all parts of the silk cocoon.

What is Spun Silk? Key Features and Production

Spun silk is produced from short fibers left over after the reeled silk threads are extracted from the cocoon, resulting in a textured, slightly matte fabric with a heavier feel compared to reeled silk. Key features of spun silk include its durability, eco-friendliness due to using silk waste, and a soft, nubby surface ideal for upholstery and casual wear. The production process involves carding and spinning the short fibers into yarn, differentiating it from the continuous filament method used for reeled silk.

Texture Differences: Silk Noil vs Spun Silk

Silk noil has a matte finish and a slightly rough, nubby texture due to the short fibers left over from processing silk cocoons, offering a more casual and rustic appearance. Spun silk, made from longer fibers, boasts a smoother, softer, and shinier surface that feels luxurious against the skin. These texture differences influence their use, with silk noil favored for everyday wear and home decor while spun silk is preferred for elegant garments and high-end textiles.

Durability and Strength Comparison

Silk noil, made from shorter silk fibers, exhibits lower tensile strength and durability compared to spun silk, which is produced from longer, continuous fibers. Spun silk's tightly twisted filaments confer greater resistance to wear and tear, making it more suitable for high-stress textile applications. The reduced fiber length in silk noil results in a softer texture but compromises its structural integrity over time.

Visual Appeal: Matte vs Sheen

Silk noil exhibits a matte finish due to its shorter fibers and irregular texture, offering a rustic and understated visual appeal ideal for casual and earthy designs. Spun silk, made from longer fibers, boasts a natural sheen that reflects light smoothly, enhancing the fabric's luxurious and elegant appearance. This lustrous quality in spun silk makes it preferred for formalwear and high-end fashion, contrasting sharply with the textured, muted look of silk noil.

Common Uses for Silk Noil and Spun Silk

Silk noil, valued for its soft texture and matte finish, is commonly used in upholstery, lightweight clothing, and home textiles due to its affordability and durability. Spun silk, with its smooth surface and lustrous sheen, is preferred for high-end fashion garments, scarves, and luxury bedding, where elegance and softness are essential. Both fabrics offer unique characteristics, making silk noil ideal for casual wear and functional textiles, while spun silk excels in premium apparel and decorative items.

Sustainability and Eco-Friendliness

Silk noil and spun silk offer sustainable alternatives in the textile industry due to their eco-friendly production processes. Silk noil utilizes shorter fibers from silk waste, reducing raw material consumption and minimizing environmental impact. Spun silk, made from reprocessed silk fibers, supports sustainability by repurposing byproducts and decreasing reliance on conventional silk farming, which demands substantial water and chemical use.

Cost Factors: Price Comparison

Silk noil is generally more affordable than spun silk due to its use of shorter fibers and less intensive processing. Spun silk, made from longer silk fibers, demands higher production costs, resulting in a significantly higher price point. The cost difference reflects the varying quality and texture, with spun silk offering a smoother finish and greater durability compared to the coarse, slubbed feel of silk noil.

Which to Choose: Silk Noil or Spun Silk?

Silk noil, derived from shorter fibers left after combing, offers a textured, matte finish with excellent breathability and durability, ideal for casual wear and home textiles. Spun silk, made from longer fibers, provides a smoother, lustrous appearance and softer feel, making it perfect for luxury garments and elegant accessories. Choosing between silk noil and spun silk depends on the desired texture, appearance, and intended use, with noil favored for comfort and durability, while spun silk excels in sheen and softness.

Silk noil vs Spun silk Infographic

materialdif.com

materialdif.com