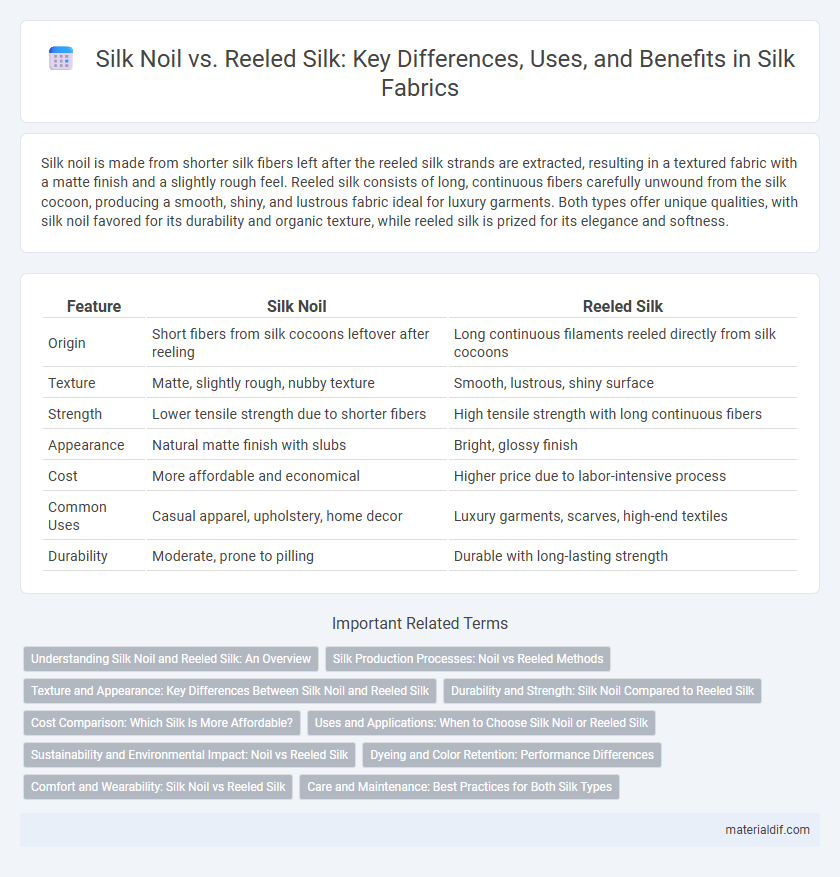

Silk noil is made from shorter silk fibers left after the reeled silk strands are extracted, resulting in a textured fabric with a matte finish and a slightly rough feel. Reeled silk consists of long, continuous fibers carefully unwound from the silk cocoon, producing a smooth, shiny, and lustrous fabric ideal for luxury garments. Both types offer unique qualities, with silk noil favored for its durability and organic texture, while reeled silk is prized for its elegance and softness.

Table of Comparison

| Feature | Silk Noil | Reeled Silk |

|---|---|---|

| Origin | Short fibers from silk cocoons leftover after reeling | Long continuous filaments reeled directly from silk cocoons |

| Texture | Matte, slightly rough, nubby texture | Smooth, lustrous, shiny surface |

| Strength | Lower tensile strength due to shorter fibers | High tensile strength with long continuous fibers |

| Appearance | Natural matte finish with slubs | Bright, glossy finish |

| Cost | More affordable and economical | Higher price due to labor-intensive process |

| Common Uses | Casual apparel, upholstery, home decor | Luxury garments, scarves, high-end textiles |

| Durability | Moderate, prone to pilling | Durable with long-lasting strength |

Understanding Silk Noil and Reeled Silk: An Overview

Silk noil consists of shorter fibers left after combing and spinning, resulting in a textured, matte fabric ideal for casual wear and upholstery. Reeled silk is produced by unwinding long, continuous filaments from silk cocoons, creating smooth, lustrous, and strong textiles preferred in luxury fashion and high-end garments. Understanding the differences in fiber length, texture, and strength helps in selecting the appropriate silk type for specific textile applications.

Silk Production Processes: Noil vs Reeled Methods

Silk production involves two primary methods: noil and reeled silk, each yielding distinct fiber qualities. Noil silk is produced from shorter, broken fibers left after the reeled silk extraction, resulting in a textured fabric with a matte finish and less sheen. Reeled silk involves unwinding long, intact filaments directly from the cocoons, producing a smooth, lustrous fabric prized for its strength and elegance in luxury textiles.

Texture and Appearance: Key Differences Between Silk Noil and Reeled Silk

Silk noil features a rougher, matte texture with a slightly nubby surface due to shorter fibers, giving it a more natural and rustic appearance. Reeled silk is smooth, glossy, and lustrous because it is made from long, continuous fibers, resulting in a luxurious, shiny finish. These textural and visual differences define their distinct uses in fashion and home textiles.

Durability and Strength: Silk Noil Compared to Reeled Silk

Silk noil fibers are shorter and less uniform compared to reeled silk, resulting in lower tensile strength and reduced durability. Reeled silk is composed of long filaments that provide superior strength and a smoother, more luxurious texture. Consequently, reeled silk garments typically exhibit enhanced longevity and resistance to wear compared to those made from silk noil.

Cost Comparison: Which Silk Is More Affordable?

Silk noil is generally more affordable than reeled silk due to its shorter fiber length and less processing required, resulting in lower production costs. Reeled silk, harvested from intact cocoons with long continuous fibers, demands delicate extraction and higher labor intensity, making it pricier. For budget-conscious buyers, silk noil offers a cost-effective alternative while maintaining key silk qualities.

Uses and Applications: When to Choose Silk Noil or Reeled Silk

Silk noil, with its rough texture and matte finish, is ideal for casual wear, home textiles, and upholstery, offering durability and affordability in products like scarves, curtains, and cushions. Reeled silk, known for its smooth, glossy surface and luxurious feel, suits high-end fashion, bridal wear, and fine accessories where softness and sheen are paramount. Choosing silk noil is practical for everyday items requiring resilience, while reeled silk is preferred for elegant garments and exquisite craftsmanship.

Sustainability and Environmental Impact: Noil vs Reeled Silk

Silk noil, derived from shorter fibers leftover from the reeling process, offers a more sustainable alternative by utilizing what would otherwise be waste, reducing environmental impact compared to reeled silk. Reeled silk involves longer fibers extracted directly from the cocoon, requiring more energy-intensive processes including boiling, which can contribute to higher resource consumption and pollution. Choosing silk noil supports eco-friendly practices by minimizing waste and lowering water and chemical use in silk production.

Dyeing and Color Retention: Performance Differences

Silk noil, composed of shorter fibers and irregular texture, absorbs dyes differently than reeled silk, often resulting in less uniform color but unique matte finishes. Reeled silk, made from long, continuous filaments, exhibits superior dye penetration and vibrant, consistent color retention due to its smooth, compact fiber structure. The molecular alignment in reeled silk also contributes to enhanced resistance against fading, making it ideal for high-performance dyeing and long-lasting color intensity.

Comfort and Wearability: Silk Noil vs Reeled Silk

Silk noil offers a textured, matte finish that provides breathability and a slightly heavier feel, making it ideal for casual, comfortable wear. Reeled silk boasts a smooth, lustrous surface with a lighter, more delicate texture that enhances softness and drapes elegantly, perfect for formal and luxury garments. Both types of silk ensure comfort, but noil silk is more durable and less slippery, while reeled silk excels in luxurious softness and sheen.

Care and Maintenance: Best Practices for Both Silk Types

Silk noil and reeled silk each require gentle care to preserve their delicate fibers; hand washing in cold water with mild detergent is recommended to prevent damage. Avoid wringing or twisting both types, and dry flat away from direct sunlight to maintain their texture and luster. Proper storage in a cool, dry place with minimal exposure to humidity helps extend the lifespan of silk noil and reeled silk garments.

Silk noil vs Reeled silk Infographic

materialdif.com

materialdif.com