Raw silk retains its natural gum, resulting in a stiffer texture and more matte appearance compared to cultivated silk, which is processed to remove the sericin and yields a softer, shinier fabric. Cultivated silk comes from domesticated silkworms fed on mulberry leaves, ensuring uniform quality and longer fibers that enhance the fabric's smoothness and strength. Raw silk's uneven texture and natural impurities give it a unique, rustic charm favored in traditional and artisanal textile designs.

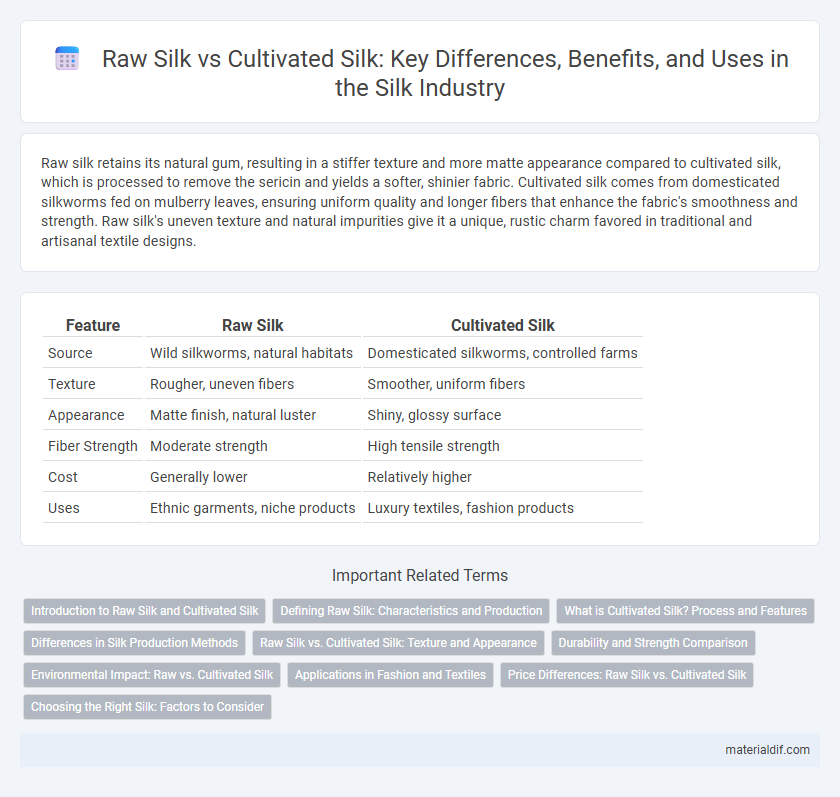

Table of Comparison

| Feature | Raw Silk | Cultivated Silk |

|---|---|---|

| Source | Wild silkworms, natural habitats | Domesticated silkworms, controlled farms |

| Texture | Rougher, uneven fibers | Smoother, uniform fibers |

| Appearance | Matte finish, natural luster | Shiny, glossy surface |

| Fiber Strength | Moderate strength | High tensile strength |

| Cost | Generally lower | Relatively higher |

| Uses | Ethnic garments, niche products | Luxury textiles, fashion products |

Introduction to Raw Silk and Cultivated Silk

Raw silk, also known as untwisted silk, retains sericin, the natural gum coating that protects the silk fibers during harvesting, resulting in a coarser texture and less sheen compared to cultivated silk. Cultivated silk is produced from domesticated silkworms, primarily the Bombyx mori, and undergoes degumming to remove sericin, yielding a smoother, finer, and more lustrous fabric widely used in high-quality textiles. The differences in processing methods and silkworm species significantly influence the strength, texture, and appearance of raw silk versus cultivated silk.

Defining Raw Silk: Characteristics and Production

Raw silk retains the sericin gum coating on the fibers, giving it a stiffer texture and a natural, slightly rough appearance compared to cultivated silk, which is degummed for softness and sheen. Produced by harvesting cocoons directly from wild silkworms, raw silk embodies organic impurities and unprocessed qualities that enhance durability and a unique tactile experience. The production process involves carefully reeling silk threads without extensive refining, preserving the sericin and resulting in a fabric prized for its authenticity and resilience.

What is Cultivated Silk? Process and Features

Cultivated silk is produced from the domesticated silkworm, primarily Bombyx mori, which feeds on mulberry leaves under controlled conditions to ensure high-quality fiber. The process involves carefully harvesting cocoons after larvae spin silk threads, followed by reeling the raw silk to create smooth, lustrous threads prized for textile production. Cultivated silk features uniform texture, superior strength, and consistent sheen, making it more commercially desirable than raw silk, which is typically coarser and less uniform due to wild silkworm origins.

Differences in Silk Production Methods

Raw silk is produced by harvesting silk fibers directly from wild silkworm cocoons, resulting in uneven, natural fibers that often retain sericin. Cultivated silk comes from domesticated silkworms carefully raised in controlled environments, yielding uniform, high-quality fibers with minimal sericin. These production methods impact texture, strength, and the overall quality of the finished silk fabric.

Raw Silk vs. Cultivated Silk: Texture and Appearance

Raw silk has a coarse texture with natural sericin coating, giving it a more rustic and matte appearance, whereas cultivated silk is smoother and glossier due to the removal of sericin during processing. The uneven fiber thickness in raw silk creates a slightly rough surface that enhances its natural and organic look, while cultivated silk boasts uniform filaments that result in a sleek, shiny finish. These differences in texture and appearance influence their applications, with raw silk favored for artisanal and textured designs and cultivated silk preferred for luxurious, smooth fabrics.

Durability and Strength Comparison

Raw silk retains sericin, which provides additional natural stiffness and enhanced durability compared to cultivated silk, making it more resistant to wear and tear. Cultivated silk fibers undergo degumming to remove sericin, resulting in a softer texture but slightly reduced tensile strength and longevity. The presence of sericin in raw silk contributes to a higher resistance against abrasion and stronger fiber integrity than the smoother, more delicate cultivated silk.

Environmental Impact: Raw vs. Cultivated Silk

Raw silk production involves harvesting silk directly from wild silkworms, leading to less controlled environmental conditions and potential disruption of natural ecosystems. Cultivated silk, derived from domesticated silkworms raised on mulberry plantations, typically results in more sustainable farming practices with lower biodiversity loss and managed resource consumption. The environmental impact of cultivated silk is generally reduced due to regulated water usage, pesticide application, and energy efficiency compared to the unpredictable methods associated with raw silk harvesting.

Applications in Fashion and Textiles

Raw silk, valued for its natural texture and uneven thickness, finds niche applications in eco-friendly and artisanal fashion pieces, offering a unique aesthetic that highlights imperfection and organic beauty. Cultivated silk, known for its smooth, uniform fibers, dominates mainstream textiles and luxury garments due to its consistent quality, strength, and versatility in dyeing and weaving processes. Both raw and cultivated silks contribute essential qualities to fashion and textiles, with raw silk appealing to sustainable fashion markets and cultivated silk driving high-volume, refined product manufacturing.

Price Differences: Raw Silk vs. Cultivated Silk

Raw silk generally commands a higher price than cultivated silk due to its limited availability and less refined processing methods. Cultivated silk, produced through controlled sericulture, offers more consistent quality and affordability, making it accessible for mass markets. Price disparities arise from factors such as production scale, labor intensity, and yarn uniformity, influencing the cost-effectiveness for textile manufacturers.

Choosing the Right Silk: Factors to Consider

Raw silk, known for its natural, uneven texture and higher sericin content, offers a more rustic and organic appearance, while cultivated silk features smoother fibers with a more refined and uniform quality due to the controlled environment of silk farming. When choosing the right silk, factors such as desired texture, durability, and intended use--whether for luxurious garments or artisanal crafts--play a critical role. Understanding the origin and processing methods helps determine the silk's strength, sheen, and suitability for specific applications.

Raw silk vs cultivated silk Infographic

materialdif.com

materialdif.com