Silk noil consists of shorter fibers left after combing raw silk, resulting in a textured, matte fabric with a slightly rough feel, ideal for casual wear and upholstery. Raw silk is made from the whole silk filament, retaining its natural gum (sericin), which gives it a crisp texture and a subtle sheen, often used for more formal garments. The key difference lies in texture and finish, where silk noil offers durability and breathability, while raw silk provides elegance and structure.

Table of Comparison

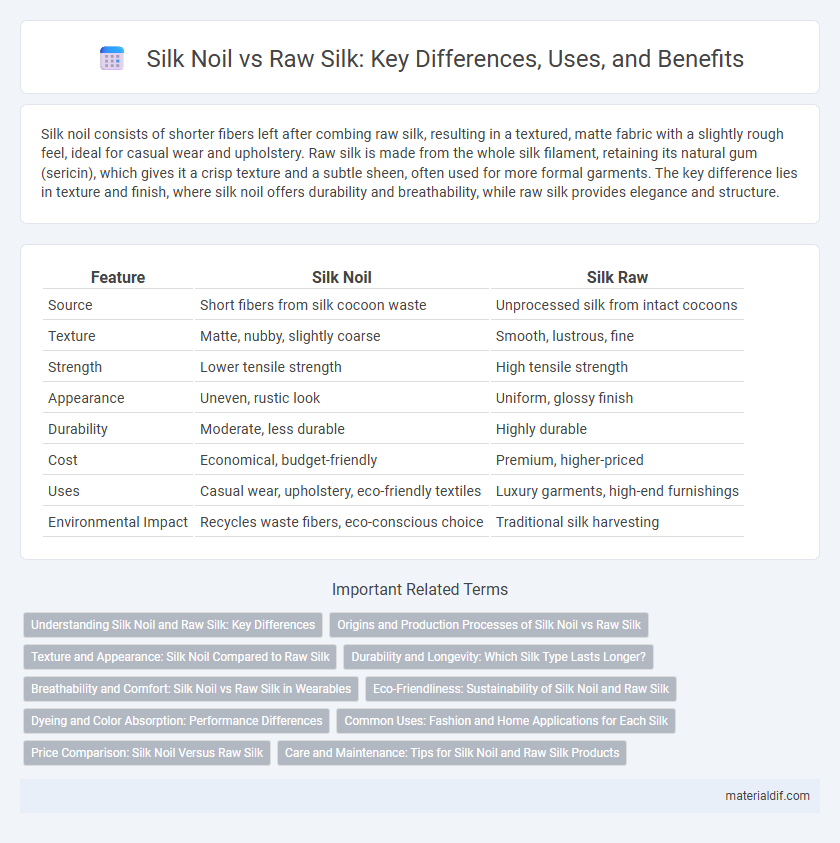

| Feature | Silk Noil | Silk Raw |

|---|---|---|

| Source | Short fibers from silk cocoon waste | Unprocessed silk from intact cocoons |

| Texture | Matte, nubby, slightly coarse | Smooth, lustrous, fine |

| Strength | Lower tensile strength | High tensile strength |

| Appearance | Uneven, rustic look | Uniform, glossy finish |

| Durability | Moderate, less durable | Highly durable |

| Cost | Economical, budget-friendly | Premium, higher-priced |

| Uses | Casual wear, upholstery, eco-friendly textiles | Luxury garments, high-end furnishings |

| Environmental Impact | Recycles waste fibers, eco-conscious choice | Traditional silk harvesting |

Understanding Silk Noil and Raw Silk: Key Differences

Silk noil consists of short, broken fibers left over from spinning raw silk, resulting in a fabric with a nubby texture and matte finish, ideal for casual wear and upholstery. Raw silk retains the sericin coating, giving it a stiffer, more lustrous appearance and requiring special care to maintain its natural sheen. Key differences include fiber length, texture, luster, and finishing processes, which influence their applications and durability.

Origins and Production Processes of Silk Noil vs Raw Silk

Silk noil is produced from the shorter fibers left after the long filaments of raw silk are extracted, primarily sourced from damaged or pupae-spun cocoons, resulting in a matte, textured fabric with a slightly rough feel. Raw silk, on the other hand, is harvested directly from intact cocoons, preserving sericin--the natural gum--giving it a smoother texture and a lustrous sheen. The production of raw silk involves careful reeling of unbroken filaments, whereas silk noil is created by spinning shorter fibers, reflecting distinct origins and manufacturing methods that impact the fabric's appearance and durability.

Texture and Appearance: Silk Noil Compared to Raw Silk

Silk noil features a rougher texture with a matte finish, characterized by its short fibers and uneven surface, while raw silk offers a smoother, more lustrous appearance due to longer fibers and minimal processing. The texture of silk noil is slightly coarse and nubby, providing a unique tactile appeal distinct from the soft, sleek feel of raw silk. Visually, silk noil tends to appear more rustic and matte, contrasting with the shiny, smooth sheen typical of raw silk fabrics.

Durability and Longevity: Which Silk Type Lasts Longer?

Silk noil, made from shorter fibers and silk waste, generally has lower durability compared to raw silk, which is composed of long, continuous filaments from the silkworm cocoon's outer layers. Raw silk exhibits greater tensile strength and resilience, resulting in enhanced longevity for textiles and garments. Choosing raw silk ensures more durable fabric that withstands wear and washing better than the comparatively fragile and less uniform silk noil.

Breathability and Comfort: Silk Noil vs Raw Silk in Wearables

Silk noil, made from shorter fibers, offers enhanced breathability and softness, making it ideal for comfortable wearables in warmer climates. Raw silk, retaining more sericin and longer fibers, provides a slightly firmer texture with moderate breathability, suitable for structured garments. Both types deliver natural moisture-wicking properties, but silk noil outperforms raw silk in lightweight comfort and air circulation.

Eco-Friendliness: Sustainability of Silk Noil and Raw Silk

Silk noil is more eco-friendly than raw silk due to its use of shorter fibers from silk waste, reducing the need for additional silkworm cultivation and minimizing environmental impact. Raw silk production involves harvesting continuous filaments from silkworm cocoons, which often requires killing the pupae, raising ethical and sustainability concerns. The sustainability of silk noil is enhanced by its utilization of leftover fibers, promoting a circular economy and reducing resource consumption compared to the more resource-intensive raw silk process.

Dyeing and Color Absorption: Performance Differences

Silk noil, composed of short fibers and lacking the smooth sericin coating present in raw silk, shows superior dye absorption due to its porous texture and increased surface area, resulting in richer and more vibrant colors. Raw silk retains sericin, which can create a barrier to dye penetration, often requiring more intensive pre-treatment to achieve uniform coloration. The difference in fiber structure and sericin presence directly influences the dyeing efficiency and colorfastness between silk noil and raw silk textiles.

Common Uses: Fashion and Home Applications for Each Silk

Silk noil, made from shorter fibers leftover after combing silk, is commonly used in casual fashion items like scarves, blouses, and lightweight jackets due to its textured, matte finish. Raw silk, which retains its sericin coating and has a slightly rougher feel, finds frequent application in home decor products such as upholstery, draperies, and cushion covers for its durability and natural sheen. Both silk types cater to fashion and interior design but differ in texture, finish, and aesthetic suited to informal wear versus premium home furnishings.

Price Comparison: Silk Noil Versus Raw Silk

Silk noil is generally more affordable than raw silk due to its shorter fiber length and more textured appearance, making it a popular choice for cost-conscious consumers. Raw silk, with its longer fibers and smoother finish, commands a higher price reflecting its premium quality and durability. The price difference between silk noil and raw silk can be significant, often influenced by factors such as fiber processing, weaving techniques, and market demand.

Care and Maintenance: Tips for Silk Noil and Raw Silk Products

Silk noil requires gentle handwashing in cold water with mild detergent to maintain its textured finish, while raw silk needs delicate care to prevent damage from rough handling or harsh chemicals. Both fabrics benefit from air drying away from direct sunlight to preserve their natural luster and strength. Regularly brushing raw silk removes surface dust, and storing silk noil in breathable bags helps avoid moisture buildup and mildew.

Silk noil vs Silk raw Infographic

materialdif.com

materialdif.com