Silk noil is made from the shorter fibers left after the longer filaments are spun, resulting in a textured, matte fabric with a nubby surface. Silk shantung is woven from long, continuous silk fibers, producing a smooth fabric with a crisp hand and subtle sheen. Both fabrics are prized in fashion, with noil offering a rustic, casual look and shantung favored for elegant, structured garments.

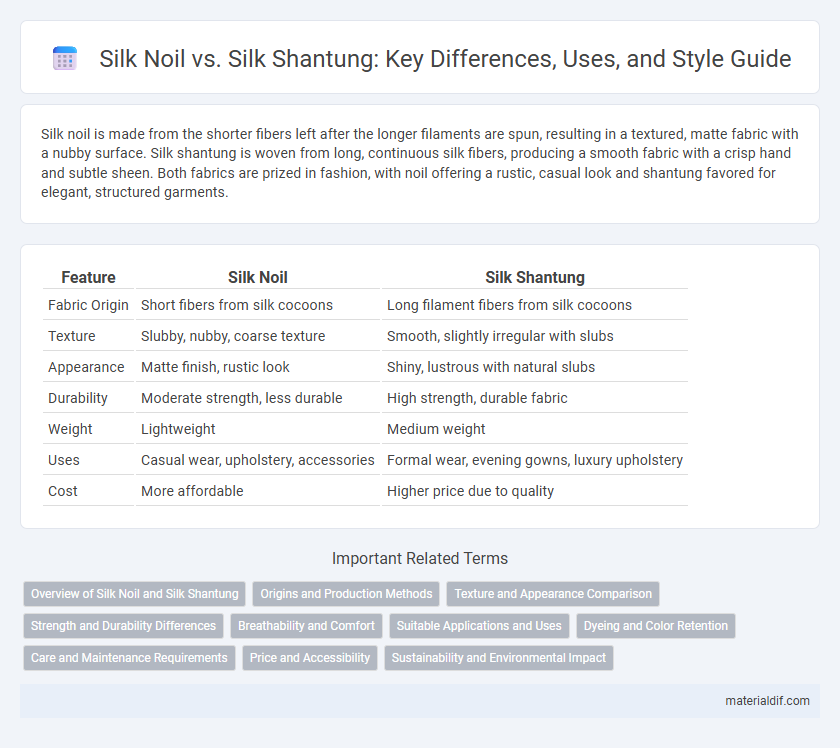

Table of Comparison

| Feature | Silk Noil | Silk Shantung |

|---|---|---|

| Fabric Origin | Short fibers from silk cocoons | Long filament fibers from silk cocoons |

| Texture | Slubby, nubby, coarse texture | Smooth, slightly irregular with slubs |

| Appearance | Matte finish, rustic look | Shiny, lustrous with natural slubs |

| Durability | Moderate strength, less durable | High strength, durable fabric |

| Weight | Lightweight | Medium weight |

| Uses | Casual wear, upholstery, accessories | Formal wear, evening gowns, luxury upholstery |

| Cost | More affordable | Higher price due to quality |

Overview of Silk Noil and Silk Shantung

Silk Noil is made from the shorter fibers left over after combing silk, resulting in a textured, matte fabric with a slightly nubby surface that is lightweight and breathable. Silk Shantung is woven from long silk fibers creating a smooth, lustrous fabric with characteristic slubs, known for its crisp drape and luxurious sheen. Both fabrics are valued in fashion and interior design, with Silk Noil offering a more casual, rustic aesthetic and Silk Shantung providing a refined, elegant appearance.

Origins and Production Methods

Silk noil is derived from the shorter, broken fibers left after reeled silk fibers are extracted from silkworm cocoons, primarily produced in China and India through degumming and carding processes. Silk shantung originates from long, filament silk fibers collected mainly in China and Japan, woven in a tight, plain weave that produces its characteristic slubby texture. The production of silk noil involves spinning shorter fibers into yarn, whereas silk shantung is made by weaving long filament threads without extensive spinning, resulting in distinct textures and finishes.

Texture and Appearance Comparison

Silk noil features a nubby, uneven texture due to short-staple fibers, creating a matte, rustic appearance ideal for casual and natural looks. In contrast, silk shantung displays a smooth, crisp surface with a lustrous sheen and distinct slubs, offering a more refined and elegant aesthetic. Both fabrics share unique textures, but silk shantung's polished finish sets it apart as a luxurious choice for formal wear.

Strength and Durability Differences

Silk noil, made from shorter fibers and silk waste, has a slightly lower strength and durability compared to silk shantung, which is woven from long, continuous silk filaments. The irregular texture of silk noil enhances breathability but reduces tensile strength and abrasion resistance, making it less suited for high-wear applications. In contrast, silk shantung's smooth, tightly woven structure provides superior durability and resilience, ideal for garments and upholstery requiring long-lasting performance.

Breathability and Comfort

Silk noil offers superior breathability and a softer, more textured feel due to its shorter fibers, making it ideal for comfortable, casual wear. Silk shantung, woven from long, continuous fibers, provides a smoother surface with a slight crispness, offering less breathability but a more structured aesthetic. Choosing between silk noil and silk shantung depends on whether enhanced airflow and comfort or a polished appearance is the priority.

Suitable Applications and Uses

Silk noil features a rougher texture and matte finish, making it ideal for casual apparel, home decor, and accessories that benefit from a natural, rustic aesthetic. Silk shantung offers a crisp, slightly lustrous surface with subtle slubs, perfect for formal wear such as evening gowns, bridal dresses, and high-end upholstery. Both fabrics excel in different applications based on their texture, durability, and appearance, with noil favored for relaxed styles and shantung chosen for elegant, structured designs.

Dyeing and Color Retention

Silk noil, made from shorter fibers, absorbs dye unevenly, resulting in a matte finish with softer color intensity, while silk shantung's longer fibers allow for more vibrant, uniform dyeing and superior color retention. The textured surface of silk noil causes slight color variation and fading over time, unlike the smooth, lustrous fibers of silk shantung that enhance dye adherence and longevity. For projects requiring vivid, lasting hues, silk shantung offers greater colorfastness compared to the naturally variegated tones of silk noil.

Care and Maintenance Requirements

Silk noil requires gentle hand washing or dry cleaning to preserve its textured surface and prevent shrinkage, while avoiding bleach and harsh detergents is essential. Silk shantung demands careful dry cleaning and delicate handling to maintain its lustrous sheen and crisp finish, as it is prone to wrinkling and snagging. Both fabrics benefit from storage in cool, dry places away from direct sunlight to prevent color fading and fiber damage.

Price and Accessibility

Silk noil is generally more affordable and accessible than silk shantung due to its use of shorter silk fibers and lower-grade raw materials, making it a popular choice for budget-conscious consumers. Silk shantung, woven from long, smooth silk filaments, commands a higher price reflecting its luxurious texture and sheen, often reserved for high-end fashion and formal wear. Availability of silk noil is widespread in both retail and wholesale markets, while silk shantung tends to be less common and more specialized, often found in boutique stores or luxury fabric suppliers.

Sustainability and Environmental Impact

Silk noil is more sustainable than silk shantung due to its use of shorter fibers left over from silk processing, minimizing waste and reducing the need for additional resource-intensive cultivation. Silk noil production consumes less water and energy compared to the more laborious creation of silk shantung, which requires long, continuous filaments from intact cocoons. Choosing silk noil supports eco-friendly fashion by promoting upcycling of materials and lowering the environmental footprint of silk textiles.

Silk noil vs silk shantung Infographic

materialdif.com

materialdif.com