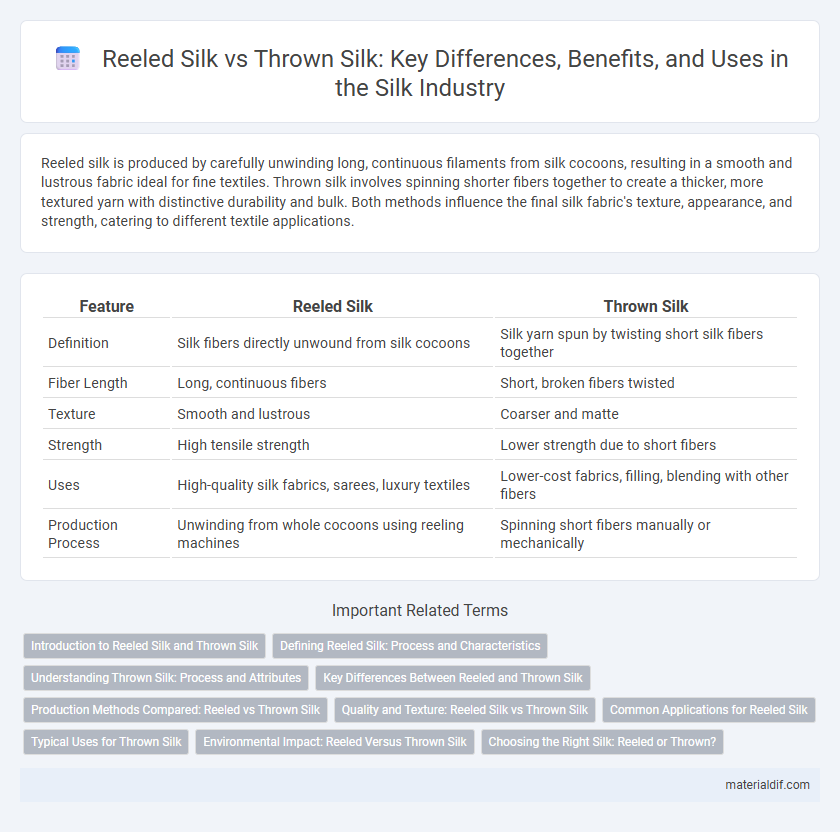

Reeled silk is produced by carefully unwinding long, continuous filaments from silk cocoons, resulting in a smooth and lustrous fabric ideal for fine textiles. Thrown silk involves spinning shorter fibers together to create a thicker, more textured yarn with distinctive durability and bulk. Both methods influence the final silk fabric's texture, appearance, and strength, catering to different textile applications.

Table of Comparison

| Feature | Reeled Silk | Thrown Silk |

|---|---|---|

| Definition | Silk fibers directly unwound from silk cocoons | Silk yarn spun by twisting short silk fibers together |

| Fiber Length | Long, continuous fibers | Short, broken fibers twisted |

| Texture | Smooth and lustrous | Coarser and matte |

| Strength | High tensile strength | Lower strength due to short fibers |

| Uses | High-quality silk fabrics, sarees, luxury textiles | Lower-cost fabrics, filling, blending with other fibers |

| Production Process | Unwinding from whole cocoons using reeling machines | Spinning short fibers manually or mechanically |

Introduction to Reeled Silk and Thrown Silk

Reeled silk is produced by unwinding long, continuous silk filaments directly from the cocoon, resulting in smooth, lustrous fibers ideal for fine textiles. Thrown silk, also known as spun silk, is made by twisting shorter or broken silk fibers together, creating a textured yarn with a slightly rougher finish often used in more durable fabrics. Both reeled and thrown silk offer distinct qualities that cater to various applications in the textile industry.

Defining Reeled Silk: Process and Characteristics

Reeled silk originates from long, continuous filaments carefully unwound from silk cocoons, preserving the fiber's smoothness, luster, and strength essential for high-quality textiles. The reeled silk production process involves boiling the cocoons to soften sericin, enabling workers to reel the filament onto spools without breaking, resulting in fine, uniform silk threads. Characterized by its glossy appearance, exceptional tensile strength, and smooth texture, reeled silk is preferred for luxury garments and delicate fabrics.

Understanding Thrown Silk: Process and Attributes

Thrown silk refers to yarn made by twisting together multiple reeled silk filaments, enhancing its strength and texture compared to single filaments. The process involves winding several smooth, continuous filaments from silk cocoons, then twisting them to create a more durable, textured yarn often used in weaving thicker fabrics. This yarn offers greater elasticity and a slightly rougher surface, making it ideal for textiles requiring resilience and enhanced tactile qualities.

Key Differences Between Reeled and Thrown Silk

Reeled silk consists of long, continuous filaments carefully unwound from silk cocoons, ensuring smoothness and uniformity, while thrown silk is made by twisting shorter silk fibers, resulting in a coarser texture and increased strength. Reeled silk offers a luxurious sheen and finer quality often preferred in high-end textiles, whereas thrown silk provides better durability suitable for embroidery and everyday use. The production process of reeled silk involves delicate handling to preserve filament integrity, contrasting with the mechanical twisting in thrown silk that enhances resilience but reduces softness.

Production Methods Compared: Reeled vs Thrown Silk

Reeled silk is produced by carefully unwinding long filaments from silk cocoons without breaking the fiber, resulting in smooth, lustrous threads ideal for high-quality fabrics. Thrown silk, on the other hand, involves twisting shorter silk fibers or waste silk to create stronger, more textured yarns used in durable textiles. The reeled silk method emphasizes filament integrity and sheen, while thrown silk prioritizes strength and versatility through filament blending and twisting.

Quality and Texture: Reeled Silk vs Thrown Silk

Reeled silk, produced from long, continuous filaments extracted directly from silk cocoons, exhibits a smooth, lustrous texture and superior strength, making it ideal for high-quality textiles. Thrown silk is created by twisting shorter fibers together, resulting in a coarser texture with less sheen and reduced tensile strength compared to reeled silk. The quality of reeled silk surpasses thrown silk in fineness and uniformity, while thrown silk offers more texture variation, often preferred in artisanal and rustic fabric applications.

Common Applications for Reeled Silk

Reeled silk, known for its long, continuous fibers, is commonly used in high-quality textiles such as luxury apparel, fine scarves, and delicate upholstery fabrics where strength and smooth texture are essential. Its consistent filament length makes it ideal for weaving elegant garments and premium home decor items that require a lustrous finish. Unlike thrown silk, reeled silk maintains superior tensile strength, making it a preferred choice for producing durable yet refined silk products.

Typical Uses for Thrown Silk

Thrown silk, produced by twisting multiple silk filaments together, is commonly used in weaving and embroidery for creating durable, textured fabrics. Its strength and elasticity make it ideal for luxury apparel, upholstery, and intricate textile art that requires enhanced durability. Thrown silk also plays a crucial role in high-quality sewing threads and decorative trims, providing both resilience and sheen.

Environmental Impact: Reeled Versus Thrown Silk

Reeled silk production generally has a lower environmental impact compared to thrown silk, as it involves unwinding filaments directly from cocoons, resulting in minimal waste and reduced energy consumption. Thrown silk, created by twisting short fibers together, often requires additional processing steps that increase resource use and pollution levels. Sustainable reeled silk methods can promote eco-friendly practices by minimizing chemical inputs and water usage throughout the production cycle.

Choosing the Right Silk: Reeled or Thrown?

Reeled silk, derived from long, continuous filaments, offers superior strength and a smoother texture, making it ideal for high-quality, lustrous fabrics. Thrown silk, composed of shorter fibers twisted together, provides greater elasticity and a more textured finish suited for durable, matte textiles. Selecting between reeled and thrown silk depends on the desired fabric characteristics, balancing sheen and strength against texture and resilience.

Reeled silk vs Thrown silk Infographic

materialdif.com

materialdif.com