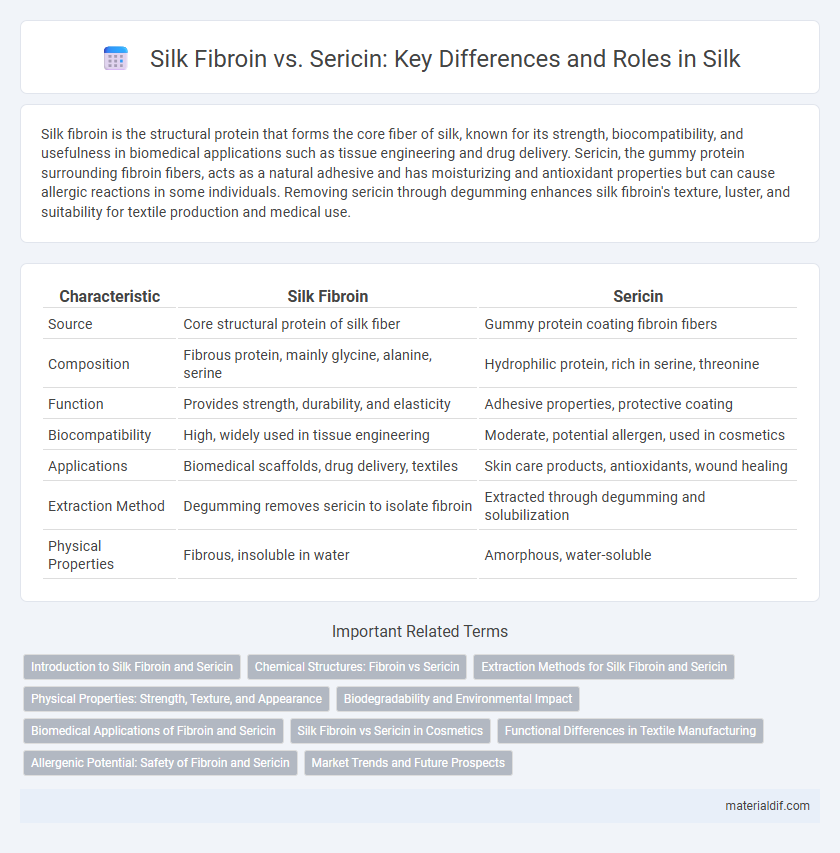

Silk fibroin is the structural protein that forms the core fiber of silk, known for its strength, biocompatibility, and usefulness in biomedical applications such as tissue engineering and drug delivery. Sericin, the gummy protein surrounding fibroin fibers, acts as a natural adhesive and has moisturizing and antioxidant properties but can cause allergic reactions in some individuals. Removing sericin through degumming enhances silk fibroin's texture, luster, and suitability for textile production and medical use.

Table of Comparison

| Characteristic | Silk Fibroin | Sericin |

|---|---|---|

| Source | Core structural protein of silk fiber | Gummy protein coating fibroin fibers |

| Composition | Fibrous protein, mainly glycine, alanine, serine | Hydrophilic protein, rich in serine, threonine |

| Function | Provides strength, durability, and elasticity | Adhesive properties, protective coating |

| Biocompatibility | High, widely used in tissue engineering | Moderate, potential allergen, used in cosmetics |

| Applications | Biomedical scaffolds, drug delivery, textiles | Skin care products, antioxidants, wound healing |

| Extraction Method | Degumming removes sericin to isolate fibroin | Extracted through degumming and solubilization |

| Physical Properties | Fibrous, insoluble in water | Amorphous, water-soluble |

Introduction to Silk Fibroin and Sericin

Silk fibroin, the structural protein of silk fibers, provides exceptional tensile strength and biocompatibility, making it ideal for biomedical and textile applications. Sericin is a gummy, water-soluble protein that envelops fibroin fibers, offering adhesive properties but often removed during processing to improve silk quality. Both proteins play distinct roles in silk's unique texture and functional characteristics, influencing its industrial and cosmetic uses.

Chemical Structures: Fibroin vs Sericin

Silk fibroin is a fibrous protein mainly composed of repetitive sequences rich in glycine, alanine, and serine, forming a beta-sheet crystalline structure responsible for its tensile strength and durability. Sericin, in contrast, is a globular hydrophilic protein with a higher molecular weight and a heterogeneous composition of polar amino acids such as serine and threonine, contributing to its adhesive and serous properties. The distinct chemical structures of fibroin and sericin determine their functional roles in silk, where fibroin provides mechanical stability and sericin acts as a natural coating and binding agent.

Extraction Methods for Silk Fibroin and Sericin

Silk fibroin is primarily extracted through degumming processes involving boiling silk cocoons in alkaline solutions, such as sodium carbonate, which removes sericin and isolates the fibroin protein. Sericin extraction typically employs methods like hot water extraction, acid treatment, or enzymatic hydrolysis to solubilize and separate sericin from silk fibers without degrading its molecular structure. Advanced techniques like ultrasonication and microwave-assisted extraction have been optimized to enhance yield and purity for both silk fibroin and sericin in biomedical and cosmetic applications.

Physical Properties: Strength, Texture, and Appearance

Silk fibroin, the primary structural protein in silk, exhibits exceptional tensile strength and a smooth, lustrous texture, contributing to its durability and elegant appearance. In contrast, sericin, the gummy protein surrounding fibroin fibers, offers a softer, sticky texture with less strength and a more matte finish. The combination of fibroin's robustness and sericin's adhesive qualities defines the unique physical properties of raw silk fibers before processing.

Biodegradability and Environmental Impact

Silk fibroin exhibits high biodegradability due to its protein-based structure, breaking down efficiently in natural environments without releasing toxic residues. In contrast, sericin degrades faster but can cause environmental issues if not properly treated, as it may increase biochemical oxygen demand in water systems. The environmentally friendly profile of silk fibroin makes it a preferred material in sustainable textile and biomedical applications.

Biomedical Applications of Fibroin and Sericin

Silk fibroin exhibits superior biocompatibility, biodegradability, and mechanical strength, making it ideal for tissue engineering, wound dressings, and drug delivery systems. Sericin, rich in hydrophilic amino acids and antioxidant properties, enhances cell adhesion, promotes skin regeneration, and serves as a natural biomaterial in cosmetic and pharmaceutical formulations. Biomedical applications leverage fibroin's structural support and sericin's bioactivity to create advanced therapeutic materials with combined functional benefits.

Silk Fibroin vs Sericin in Cosmetics

Silk fibroin and sericin are key proteins in silk, each offering unique benefits for cosmetics. Silk fibroin, known for its film-forming properties, enhances skin elasticity, hydration, and smoothness by creating a breathable barrier that protects against moisture loss. Sericin provides antioxidant and moisturizing effects, improving skin's texture and promoting a radiant complexion, but silk fibroin's superior bioavailability makes it the preferred choice in advanced skincare formulations.

Functional Differences in Textile Manufacturing

Silk fibroin provides exceptional strength, flexibility, and durability, making it ideal for producing high-quality, long-lasting textiles with a smooth and lustrous finish. Sericin, a gummy protein, acts as a natural binding agent during silk filament formation but is typically removed to improve fabric softness, dye absorption, and breathability in textile manufacturing. Fibroin's structural properties enhance mechanical performance, while sericin influences surface characteristics and processing efficiency in silk fabric production.

Allergenic Potential: Safety of Fibroin and Sericin

Silk fibroin exhibits low allergenic potential, making it highly suitable for biomedical applications such as wound dressings and tissue engineering due to its biocompatibility and minimal immune response. In contrast, sericin is more likely to cause allergic reactions because its protein structure can trigger hypersensitivity in sensitive individuals. Removing sericin through degumming processes enhances the safety of silk products by reducing immunogenicity and improving compatibility for medical and cosmetic uses.

Market Trends and Future Prospects

Silk fibroin dominates the global silk biomaterials market due to its superior mechanical strength, biocompatibility, and versatility in biomedical applications such as tissue engineering and drug delivery. Sericin, once considered a waste byproduct, is gaining traction for its antioxidant, moisturizing, and anti-inflammatory properties, driving innovation in cosmetics and wound care industries. Increasing research investments and sustainable production methods signal robust market growth for both fibroin and sericin, with future prospects favoring integrated applications that leverage their complementary bioactivities.

Silk fibroin vs Sericin Infographic

materialdif.com

materialdif.com