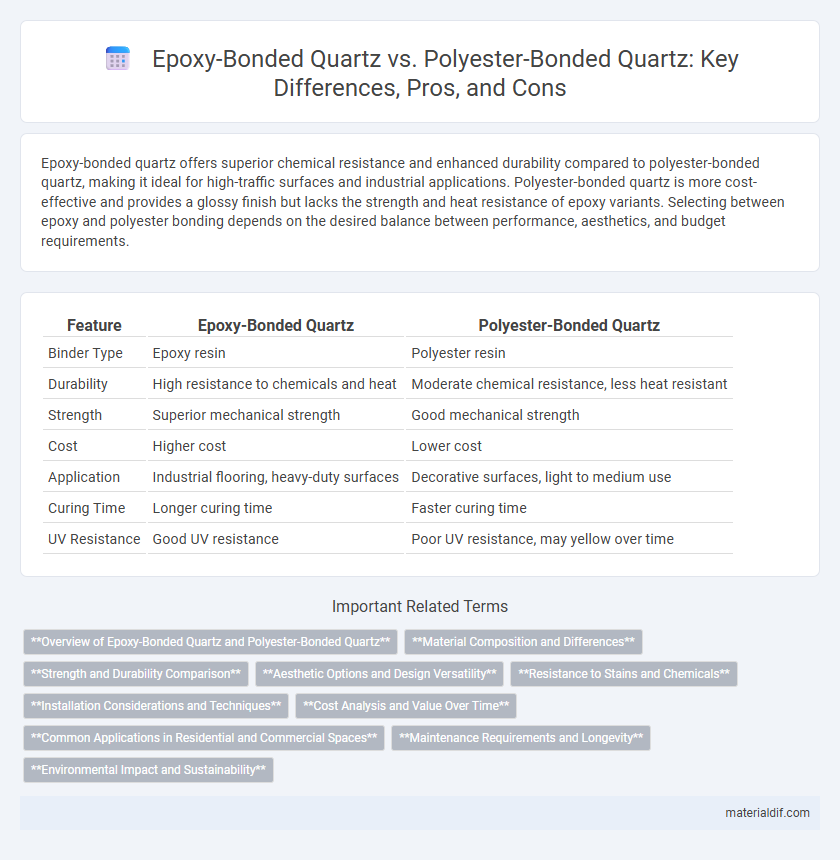

Epoxy-bonded quartz offers superior chemical resistance and enhanced durability compared to polyester-bonded quartz, making it ideal for high-traffic surfaces and industrial applications. Polyester-bonded quartz is more cost-effective and provides a glossy finish but lacks the strength and heat resistance of epoxy variants. Selecting between epoxy and polyester bonding depends on the desired balance between performance, aesthetics, and budget requirements.

Table of Comparison

| Feature | Epoxy-Bonded Quartz | Polyester-Bonded Quartz |

|---|---|---|

| Binder Type | Epoxy resin | Polyester resin |

| Durability | High resistance to chemicals and heat | Moderate chemical resistance, less heat resistant |

| Strength | Superior mechanical strength | Good mechanical strength |

| Cost | Higher cost | Lower cost |

| Application | Industrial flooring, heavy-duty surfaces | Decorative surfaces, light to medium use |

| Curing Time | Longer curing time | Faster curing time |

| UV Resistance | Good UV resistance | Poor UV resistance, may yellow over time |

Overview of Epoxy-Bonded Quartz and Polyester-Bonded Quartz

Epoxy-bonded quartz consists of quartz aggregates held together by a durable epoxy resin, providing superior mechanical strength, chemical resistance, and thermal stability ideal for industrial flooring and countertops. Polyester-bonded quartz uses polyester resin as the binder, which offers good aesthetic appeal and affordability but has lower chemical resistance and thermal tolerance compared to epoxy. The choice between epoxy and polyester-bonded quartz depends on application requirements, with epoxy preferred for heavy-duty and high-performance environments and polyester suited for decorative or less demanding uses.

Material Composition and Differences

Epoxy-bonded quartz utilizes epoxy resin as the adhesive matrix, providing superior chemical resistance, thermal stability, and mechanical strength compared to polyester-bonded quartz, which employs polyester resin known for lower heat resistance and potential yellowing over time. The epoxy resin in epoxy-bonded quartz enhances durability in high-stress environments, making it ideal for industrial and laboratory applications, whereas polyester-bonded quartz is more suited for decorative purposes due to its cost-effectiveness and ease of fabrication. Differences in resin composition directly impact the quartz's performance characteristics, including bonding integrity, UV resistance, and long-term maintenance requirements.

Strength and Durability Comparison

Epoxy-bonded quartz exhibits superior strength and durability compared to polyester-bonded quartz, due to epoxy resin's higher chemical resistance and enhanced mechanical properties. The epoxy matrix provides increased adhesion and impact resistance, resulting in improved longevity in harsh environments. Polyester-bonded quartz tends to have lower tensile strength and is more susceptible to UV degradation, making it less durable for long-term or heavy-duty applications.

Aesthetic Options and Design Versatility

Epoxy-bonded quartz offers superior aesthetic options with its clear, glossy finish that enhances the natural sparkle and color variations of quartz aggregates, making it ideal for high-end decorative surfaces. Polyester-bonded quartz provides design versatility through its broader color palette and ability to incorporate pigments and additives, allowing for customized hues and textures suitable for both functional and artistic applications. Both materials enable diverse design possibilities, but epoxy resins tend to deliver a more vibrant and durable finish, favored in architectural and luxury interior projects.

Resistance to Stains and Chemicals

Epoxy-bonded quartz exhibits superior resistance to stains and chemicals compared to polyester-bonded quartz, making it ideal for environments prone to spills and harsh cleaning agents. The dense epoxy resin creates a non-porous surface that prevents absorption of liquids and mitigates discoloration from acids, alkalis, and oils. Polyester-bonded quartz, while durable, tends to be more susceptible to staining and chemical damage due to its less robust resin matrix.

Installation Considerations and Techniques

Epoxy-bonded quartz requires careful surface preparation with a clean, dry substrate to ensure optimal adhesion and typically necessitates a longer curing time compared to polyester-bonded quartz. Polyester-bonded quartz offers faster curing and easier handling but demands precise temperature control during installation to prevent premature hardening and achieve a smooth finish. Both materials benefit from the application of primers and strict adherence to mixing ratios to enhance bond strength and durability during installation.

Cost Analysis and Value Over Time

Epoxy-bonded quartz typically incurs higher initial costs due to the superior durability and chemical resistance of epoxy resins, providing extended lifespan and reduced maintenance expenses. Polyester-bonded quartz offers a lower upfront investment but may require more frequent repairs or replacements, increasing total cost over time. When evaluating value, epoxy bonding delivers better long-term returns through enhanced performance and resilience in demanding applications.

Common Applications in Residential and Commercial Spaces

Epoxy-bonded quartz is widely used in residential countertops and commercial flooring due to its superior chemical resistance, durability, and high tensile strength, making it ideal for kitchens and high-traffic areas. Polyester-bonded quartz finds applications in decorative wall panels and furniture surfaces where cost-effectiveness and ease of fabrication are prioritized, commonly seen in retail and office interiors. Both materials offer tailored solutions in residential and commercial spaces, with epoxy-based quartz favored for heavy-duty environments and polyester-based quartz for aesthetic, budget-conscious projects.

Maintenance Requirements and Longevity

Epoxy-bonded quartz surfaces exhibit superior durability and resistance to wear, significantly reducing maintenance frequency compared to polyester-bonded quartz. The chemical stability of epoxy resin enhances longevity by preventing yellowing and degradation under UV exposure, extending the lifespan of the quartz surface. Polyester-bonded quartz, while cost-effective, typically demands more frequent upkeep and replacement due to its lower resistance to heat and chemicals.

Environmental Impact and Sustainability

Epoxy-bonded quartz demonstrates lower environmental impact due to its superior durability and chemical resistance, reducing the frequency of replacement and waste generation. Polyester-bonded quartz typically involves higher volatile organic compound (VOC) emissions during production, contributing to environmental pollution and posing sustainability concerns. Selecting epoxy-based binders supports eco-friendly building practices by minimizing toxic emissions and enhancing material longevity.

Epoxy-Bonded Quartz vs Polyester-Bonded Quartz Infographic

materialdif.com

materialdif.com