Sulfate pulp, also known as kraft pulp, is produced through a chemical process using sodium hydroxide and sodium sulfide, resulting in strong and durable fibers ideal for high-quality paper products. Sulfite pulp is made using acidic solutions of sulfurous acid and bisulfite ions, yielding softer fibers that are easier to bleach but generally weaker than sulfate pulp. The choice between sulfate and sulfite pulp affects the paper's strength, brightness, and environmental impact, with sulfate pulp offering superior strength and better chemical recovery options.

Table of Comparison

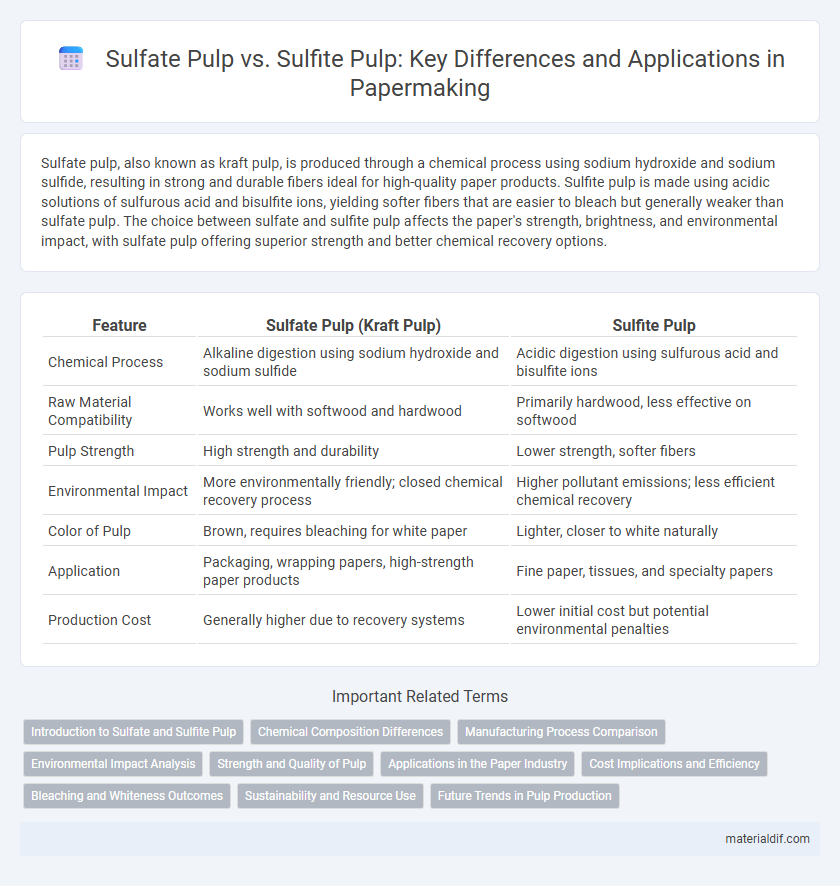

| Feature | Sulfate Pulp (Kraft Pulp) | Sulfite Pulp |

|---|---|---|

| Chemical Process | Alkaline digestion using sodium hydroxide and sodium sulfide | Acidic digestion using sulfurous acid and bisulfite ions |

| Raw Material Compatibility | Works well with softwood and hardwood | Primarily hardwood, less effective on softwood |

| Pulp Strength | High strength and durability | Lower strength, softer fibers |

| Environmental Impact | More environmentally friendly; closed chemical recovery process | Higher pollutant emissions; less efficient chemical recovery |

| Color of Pulp | Brown, requires bleaching for white paper | Lighter, closer to white naturally |

| Application | Packaging, wrapping papers, high-strength paper products | Fine paper, tissues, and specialty papers |

| Production Cost | Generally higher due to recovery systems | Lower initial cost but potential environmental penalties |

Introduction to Sulfate and Sulfite Pulp

Sulfate pulp, also known as Kraft pulp, is produced through the alkaline cooking of wood chips using sodium hydroxide and sodium sulfide, resulting in stronger fibers and higher yield. Sulfite pulp is made by chemically treating wood chips with sulfurous acid and bisulfite ions in an acidic environment, which produces a pulp with better brightness and easier bleaching potential. Both pulping processes are fundamental in the paper industry, with sulfate pulping favored for its durability and sulfite pulping valued for fine paper grades.

Chemical Composition Differences

Sulfate pulp, also known as kraft pulp, is produced using an alkaline process that primarily removes lignin while preserving cellulose fibers, resulting in higher strength pulp with lower residual lignin content compared to sulfite pulp. Sulfite pulp is produced through an acidic or neutral sulfite process that produces pulp with higher hemicellulose content and lower cellulose purity due to partial degradation of cellulose chains. The chemical differences between sulfate and sulfite pulps influence their fiber strength, brightness, and suitability for applications like packaging or fine paper production.

Manufacturing Process Comparison

Sulfate pulp, produced through the kraft process, involves cooking wood chips in a highly alkaline solution containing sodium hydroxide and sodium sulfide, which efficiently breaks down lignin and preserves cellulose fibers. Sulfite pulp manufacturing uses an acidic cooking liquor made from sulfurous acid and bisulfite ions, resulting in better pulp brightness but lower strength compared to kraft pulp. The kraft process offers higher yield and versatility in raw material use, while sulfite pulping requires more careful control of pH and temperature to prevent excessive degradation.

Environmental Impact Analysis

Sulfate pulp production generates higher levels of lignin-free pulp, resulting in less chemical consumption and improved biodegradability compared to sulfite pulp, which relies on sulfurous acid and produces more acidic wastewaters. The sulfite process emits significant quantities of sulfur oxides, contributing to acid rain and air pollution, whereas sulfate pulping mainly releases reduced sulfur compounds that are easier to manage with modern recovery systems. Lifecycle assessments indicate that sulfate pulp has a lower overall environmental footprint due to more efficient chemical recycling and lower effluent toxicity in aquatic ecosystems.

Strength and Quality of Pulp

Sulfate pulp, also known as kraft pulp, exhibits superior strength and durability compared to sulfite pulp due to its lignin removal process, which preserves the cellulose fibers more effectively. The higher tensile strength and tear resistance of sulfate pulp make it ideal for producing high-quality paper products requiring robustness, such as packaging and industrial papers. Sulfite pulp, while softer and more absorbent, generally lacks the mechanical strength of sulfate pulp and is better suited for fine papers where softness and printability are prioritized.

Applications in the Paper Industry

Sulfate pulp, also known as kraft pulp, is widely used in the paper industry due to its high strength and durability, making it ideal for packaging materials, corrugated boards, and sack papers. Sulfite pulp offers superior brightness and is preferred for producing high-quality printing and writing papers, tissue, and specialty papers requiring smooth texture and printability. The choice between sulfate and sulfite pulp depends on the desired paper characteristics, production efficiency, and end-use applications within the paper manufacturing process.

Cost Implications and Efficiency

Sulfate pulp production incurs lower operational costs due to the use of a more robust chemical recovery system, enhancing overall process efficiency compared to sulfite pulp. Sulfite pulp requires more expensive chemicals and experiences slower cooking times, resulting in higher energy consumption and reduced throughput. These factors make sulfate pulp a more cost-effective choice for large-scale paper manufacturing while maintaining comparable fiber quality.

Bleaching and Whiteness Outcomes

Sulfate pulp, known for its higher lignin removal efficiency, generally achieves better bleaching results and higher whiteness levels compared to sulfite pulp, which retains more lignin due to its milder cooking conditions. Bleaching sulfate pulp often requires fewer chemical stages and results in brighter, more stable whiteness, suitable for high-quality printing papers. In contrast, sulfite pulp tends to produce softer fibers with lower brightness, necessitating additional bleaching chemicals to reach comparable whiteness outcomes.

Sustainability and Resource Use

Sulfate pulp, also known as kraft pulp, generally has a higher yield and better fiber strength, enabling more efficient use of wood resources compared to sulfite pulp, which relies on harsher chemicals and produces lower yields. The kraft process allows for effective chemical recovery and energy generation through black liquor combustion, making it more sustainable by reducing waste and energy consumption. Sulfite pulp production tends to have higher environmental impacts due to limited chemical recovery options and greater effluent treatment challenges, which affect its overall resource efficiency and sustainability profile.

Future Trends in Pulp Production

Future trends in pulp production emphasize sustainability and efficiency between sulfate pulp and sulfite pulp processes. Sulfate pulp, known for its stronger fibers and adaptability to hardwood and softwood, is expected to dominate due to advancements in chemical recovery and energy-saving technologies. Research into sulfite pulp continues around improving environmental impact and cost-effectiveness, with biorefinery integration and enzymatic treatment showing promising developments.

Sulfate pulp vs Sulfite pulp Infographic

materialdif.com

materialdif.com