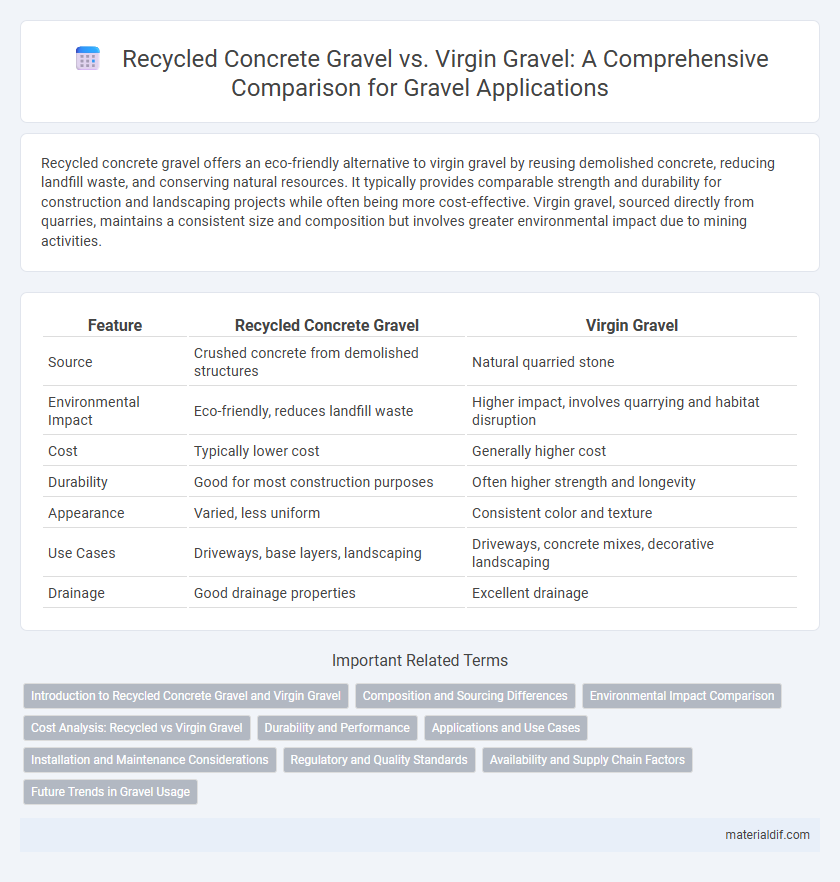

Recycled concrete gravel offers an eco-friendly alternative to virgin gravel by reusing demolished concrete, reducing landfill waste, and conserving natural resources. It typically provides comparable strength and durability for construction and landscaping projects while often being more cost-effective. Virgin gravel, sourced directly from quarries, maintains a consistent size and composition but involves greater environmental impact due to mining activities.

Table of Comparison

| Feature | Recycled Concrete Gravel | Virgin Gravel |

|---|---|---|

| Source | Crushed concrete from demolished structures | Natural quarried stone |

| Environmental Impact | Eco-friendly, reduces landfill waste | Higher impact, involves quarrying and habitat disruption |

| Cost | Typically lower cost | Generally higher cost |

| Durability | Good for most construction purposes | Often higher strength and longevity |

| Appearance | Varied, less uniform | Consistent color and texture |

| Use Cases | Driveways, base layers, landscaping | Driveways, concrete mixes, decorative landscaping |

| Drainage | Good drainage properties | Excellent drainage |

Introduction to Recycled Concrete Gravel and Virgin Gravel

Recycled concrete gravel is produced by crushing and processing concrete debris from demolished structures, offering an eco-friendly alternative to virgin gravel by reducing landfill waste and conserving natural resources. Virgin gravel is naturally extracted from quarries and riverbeds, consisting of raw, unprocessed stone commonly used in construction and landscaping for its durability and clean composition. Comparing both materials highlights the environmental benefits of recycled concrete gravel while considering the strength and consistency provided by virgin gravel in various applications.

Composition and Sourcing Differences

Recycled concrete gravel consists primarily of crushed concrete debris sourced from demolished structures, containing cement remnants, aggregates, and sometimes embedded rebar, while virgin gravel is naturally extracted from quarries, composed of natural aggregates like sand, pebbles, and crushed rock. The composition of recycled concrete gravel often includes a blend of various concrete pieces and impurities, affecting its porosity and strength, whereas virgin gravel maintains consistent mineral content and particle size due to its geological origin. Sourcing recycled concrete gravel supports sustainable construction practices by diverting waste from landfills, contrasting with the environmental impact of mining virgin gravel from natural deposits.

Environmental Impact Comparison

Recycled concrete gravel significantly reduces environmental impact by diverting demolition waste from landfills and lowering the need for new quarrying, thereby preserving natural habitats and reducing carbon emissions associated with extraction processes. Virgin gravel extraction involves disruptive mining activities that cause habitat destruction, increased erosion, and higher energy consumption due to heavy machinery usage and transportation. Choosing recycled concrete gravel supports sustainable construction practices through resource conservation and waste reduction, contributing to a smaller overall carbon footprint in infrastructure projects.

Cost Analysis: Recycled vs Virgin Gravel

Recycled concrete gravel typically costs 30-50% less than virgin gravel due to lower material and transportation expenses. Virgin gravel involves higher extraction and processing fees, driving up overall project costs. Choosing recycled concrete gravel can significantly reduce aggregate expenses while supporting sustainable construction practices.

Durability and Performance

Recycled concrete gravel offers comparable durability to virgin gravel, making it a reliable option for various construction projects. Studies show that recycled gravel exhibits strong load-bearing capacity and resistance to wear, often matching or exceeding that of virgin materials. Its performance in drainage and compaction applications also supports long-term stability in pavement and landscaping uses.

Applications and Use Cases

Recycled concrete gravel is widely used in road base construction, drainage systems, and landscaping due to its cost-effectiveness and environmental benefits, making it ideal for sustainable urban development projects. Virgin gravel, known for its consistent strength and angularity, is preferred in high-load applications such as structural foundations, concrete production, and heavy-duty pavements. Both materials serve critical roles, with recycled concrete gravel offering eco-friendly solutions while virgin gravel ensures superior durability in infrastructure.

Installation and Maintenance Considerations

Recycled concrete gravel offers improved compaction and drainage during installation compared to virgin gravel, reducing settling issues over time. Maintenance of recycled concrete gravel typically requires less frequent replenishment due to its durability and resistance to weathering. Virgin gravel may necessitate more regular leveling and weed control to maintain surface stability and aesthetics.

Regulatory and Quality Standards

Recycled concrete gravel must meet stringent regulatory standards such as ASTM C33 for concrete aggregates to ensure durability and safety in construction applications. Virgin gravel, sourced naturally, typically adheres to consistent quality benchmarks set by agencies like the USGS and local environmental regulations, guaranteeing stable particle size and minimal impurities. Compliance with these quality and regulatory standards directly impacts the structural integrity and environmental sustainability of projects utilizing either recycled or virgin gravel.

Availability and Supply Chain Factors

Recycled concrete gravel benefits from a more localized and sustainable supply chain, reducing dependency on natural quarrying and minimizing transportation costs. Virgin gravel availability is often constrained by regional geological deposits, leading to fluctuating supply and price volatility due to extraction regulations and environmental restrictions. The growing demand for eco-friendly construction materials increasingly favors recycled concrete gravel, enhancing its accessibility compared to traditional virgin gravel sources.

Future Trends in Gravel Usage

Recycled concrete gravel is gaining traction due to sustainability goals and increasing construction waste recycling rates, forecasting a significant reduction in reliance on virgin gravel sources. Innovations in processing technology enhance the quality and durability of recycled aggregates, making them competitive alternatives for infrastructure projects. Market trends indicate a growing preference for eco-friendly materials, driven by stricter environmental regulations and rising demand for green construction.

Recycled Concrete Gravel vs Virgin Gravel Infographic

materialdif.com

materialdif.com