Granite dry sawing allows for faster cutting and easier portability without the need for water, making it ideal for on-site projects and reducing water disposal concerns. Wet sawing, however, minimizes dust and cools the blade, extending tool life and improving cut quality with smoother edges. Choosing between dry and wet sawing depends on factors like project scale, environmental considerations, and desired finish quality.

Table of Comparison

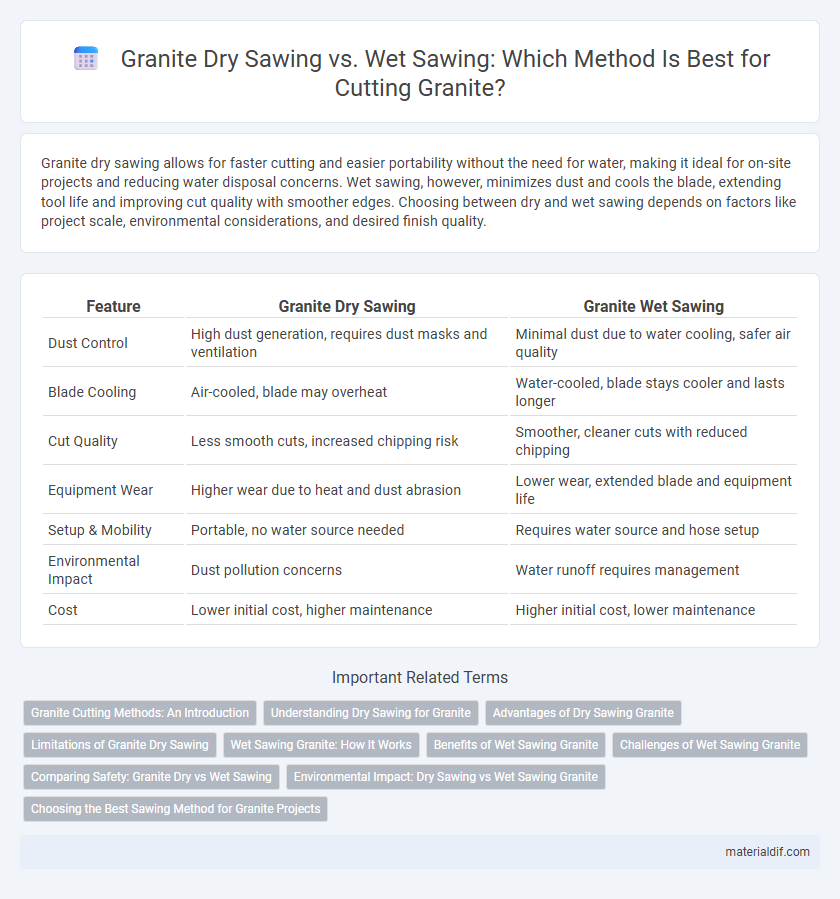

| Feature | Granite Dry Sawing | Granite Wet Sawing |

|---|---|---|

| Dust Control | High dust generation, requires dust masks and ventilation | Minimal dust due to water cooling, safer air quality |

| Blade Cooling | Air-cooled, blade may overheat | Water-cooled, blade stays cooler and lasts longer |

| Cut Quality | Less smooth cuts, increased chipping risk | Smoother, cleaner cuts with reduced chipping |

| Equipment Wear | Higher wear due to heat and dust abrasion | Lower wear, extended blade and equipment life |

| Setup & Mobility | Portable, no water source needed | Requires water source and hose setup |

| Environmental Impact | Dust pollution concerns | Water runoff requires management |

| Cost | Lower initial cost, higher maintenance | Higher initial cost, lower maintenance |

Granite Cutting Methods: An Introduction

Granite dry sawing involves cutting granite without water, producing faster cuts but generating significant dust that requires effective ventilation systems. Wet sawing uses water to cool the blade and reduce dust, providing smoother cuts and extending blade life, making it ideal for precision work on granite slabs. Choosing between dry and wet sawing depends on factors like job size, workspace conditions, and desired finish quality in granite cutting projects.

Understanding Dry Sawing for Granite

Dry sawing granite uses a blade without water, producing dust and requiring strong dust control measures to maintain air quality. Specialized diamond blades designed for dry cutting prevent overheating and prolong tool life while maintaining precision. Dry sawing allows for greater portability and convenience on sites lacking water access but necessitates frequent blade cooling and dust extraction systems.

Advantages of Dry Sawing Granite

Dry sawing granite offers advantages such as increased portability and convenience since it eliminates the need for water supply and management on-site. This method reduces the risk of water damage to surrounding materials and structural components, making it ideal for indoor environments or areas with limited drainage. Dry sawing also enables faster cutting speeds and easier cleanup, enhancing overall efficiency in granite fabrication and installation projects.

Limitations of Granite Dry Sawing

Granite dry sawing generates significant dust, posing health risks and requiring specialized dust extraction systems to ensure worker safety. The absence of water cooling leads to increased blade wear and higher operational costs due to more frequent blade replacements. Heat buildup during dry sawing can cause microfractures in the granite, compromising the stone's structural integrity and finish quality.

Wet Sawing Granite: How It Works

Wet sawing granite involves using a diamond-tipped blade continuously cooled by water to reduce friction and heat, preventing blade damage and minimizing dust. The water acts as a lubricant to ensure smooth cutting and improve the precision of the saw, extending the blade's lifespan. This method is especially effective for thick or dense granite slabs, producing cleaner cuts and reducing the risk of cracks or chips.

Benefits of Wet Sawing Granite

Wet sawing granite significantly reduces dust production, enhancing worker safety and minimizing environmental impact. The continuous water flow cools the blade, extending its lifespan and maintaining cutting efficiency. This method produces smoother cuts and minimizes chipping, ensuring higher precision and better quality granite surfaces.

Challenges of Wet Sawing Granite

Wet sawing granite involves constant water application to cool the blade and suppress dust, but it presents challenges such as managing slurry disposal and preventing water contamination. The continuous water flow can cause slippery work surfaces, increasing the risk of accidents and requiring additional safety measures. Equipment maintenance becomes more demanding due to potential water damage and the need to regularly clean both the saw and surrounding area to avoid buildup of granite dust mixed with water.

Comparing Safety: Granite Dry vs Wet Sawing

Granite dry sawing generates significant dust, posing respiratory hazards without proper ventilation or dust extraction systems, whereas wet sawing effectively suppresses dust, reducing inhalation risks and promoting a safer work environment. Dry sawing increases the likelihood of blade overheating and sudden blade failure, which can lead to serious injuries, while wet sawing cools the blade and minimizes these mechanical risks. Overall, wet sawing enhances worker safety by controlling airborne particles and maintaining blade integrity during granite cutting operations.

Environmental Impact: Dry Sawing vs Wet Sawing Granite

Dry sawing granite generates airborne dust containing silica particles, posing respiratory health risks and contributing to local air pollution. Wet sawing uses water to suppress dust, reducing airborne particles but creating slurry wastewater that requires proper disposal to prevent soil and water contamination. Choosing between dry and wet sawing impacts environmental sustainability by balancing air quality concerns against water resource management challenges.

Choosing the Best Sawing Method for Granite Projects

Granite dry sawing offers faster cuts and reduced cleanup but can generate dust that necessitates protective measures, while wet sawing minimizes dust and reduces blade heat, extending blade life and improving cut quality. Selecting the best sawing method depends on project scale, environmental conditions, and equipment availability, with wet sawing preferred for precision and health safety in indoor or large-scale operations. Evaluating factors like cost, safety regulations, and desired finish ensures optimal performance and durability in granite fabrication.

Granite Dry Sawing vs Wet Sawing Infographic

materialdif.com

materialdif.com