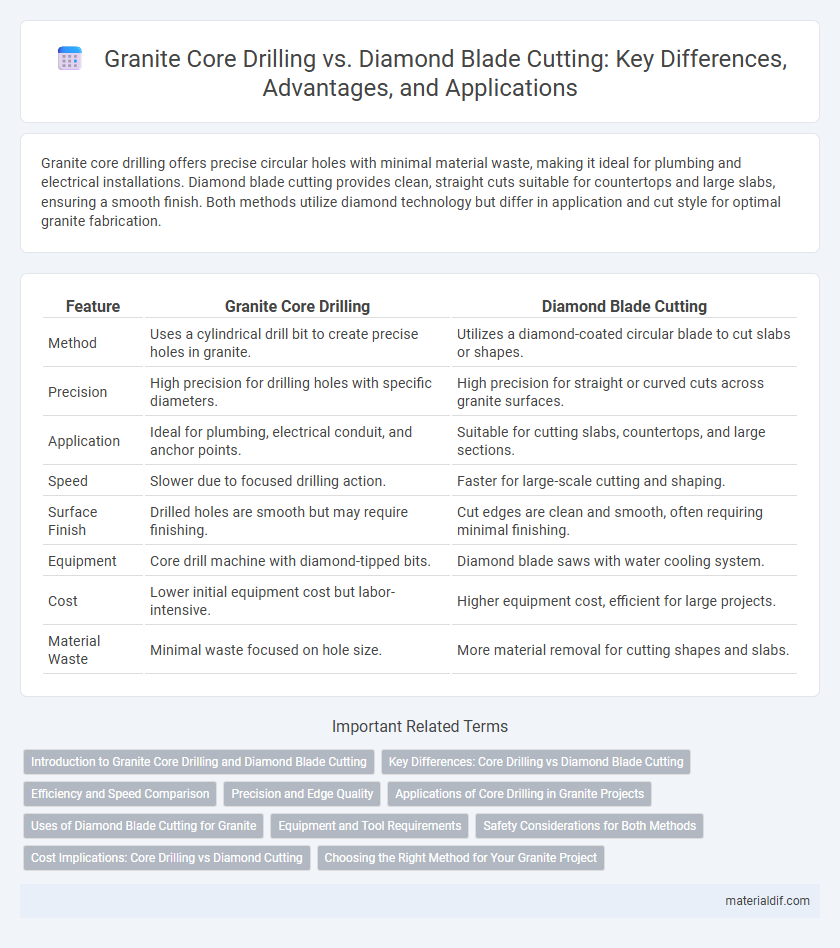

Granite core drilling offers precise circular holes with minimal material waste, making it ideal for plumbing and electrical installations. Diamond blade cutting provides clean, straight cuts suitable for countertops and large slabs, ensuring a smooth finish. Both methods utilize diamond technology but differ in application and cut style for optimal granite fabrication.

Table of Comparison

| Feature | Granite Core Drilling | Diamond Blade Cutting |

|---|---|---|

| Method | Uses a cylindrical drill bit to create precise holes in granite. | Utilizes a diamond-coated circular blade to cut slabs or shapes. |

| Precision | High precision for drilling holes with specific diameters. | High precision for straight or curved cuts across granite surfaces. |

| Application | Ideal for plumbing, electrical conduit, and anchor points. | Suitable for cutting slabs, countertops, and large sections. |

| Speed | Slower due to focused drilling action. | Faster for large-scale cutting and shaping. |

| Surface Finish | Drilled holes are smooth but may require finishing. | Cut edges are clean and smooth, often requiring minimal finishing. |

| Equipment | Core drill machine with diamond-tipped bits. | Diamond blade saws with water cooling system. |

| Cost | Lower initial equipment cost but labor-intensive. | Higher equipment cost, efficient for large projects. |

| Material Waste | Minimal waste focused on hole size. | More material removal for cutting shapes and slabs. |

Introduction to Granite Core Drilling and Diamond Blade Cutting

Granite core drilling utilizes a cylindrical diamond-tipped bit to create precise, deep holes through granite surfaces, enabling tasks like plumbing, electrical conduit installation, and anchoring. Diamond blade cutting employs abrasive diamond-coated circular blades that slice through granite slabs with high accuracy for countertops, tiles, and structural modifications. Both techniques harness the hardness and durability of industrial diamonds to efficiently penetrate dense granite material with minimal damage.

Key Differences: Core Drilling vs Diamond Blade Cutting

Core drilling in granite involves using a hollow cylindrical drill bit embedded with industrial diamonds to extract precise cylindrical samples or holes, ensuring minimal material waste and high accuracy in depth and diameter. Diamond blade cutting utilizes a circular saw blade embedded with diamonds to slice through granite slabs or blocks, offering faster surface cuts but generating rougher edges and more dust compared to core drilling. Core drilling excels in creating controlled, deep holes with clean edges, while diamond blade cutting is preferred for broad, straight cuts in granite fabrication and construction.

Efficiency and Speed Comparison

Granite core drilling offers precise, circular holes with minimal material waste, making it highly efficient for plumbing and electrical installations. Diamond blade cutting delivers faster results in creating straight cuts but generates more dust and requires cooling to prevent blade wear. Overall, core drilling excels in accuracy and reduced debris, while diamond blade cutting provides quicker, larger-scale material removal.

Precision and Edge Quality

Granite core drilling offers superior precision by creating clean, round holes with minimal vibration, preserving the granite's structural integrity. Diamond blade cutting, while efficient for straight cuts, can sometimes cause micro-fractures or chipping along edges due to blade vibration. The edge quality in core drilling is notably smoother and more consistent, making it ideal for detailed architectural and countertop applications.

Applications of Core Drilling in Granite Projects

Core drilling in granite projects is essential for creating precise, circular holes needed for plumbing, electrical conduits, and anchoring systems in structural installations. This technique allows for minimal surface damage and high accuracy in dense granite compared to diamond blade cutting, which is more suited for straight cuts and shaping slabs. Core drilling is especially valuable in infrastructure and architectural projects requiring deep penetrations through thick granite sections.

Uses of Diamond Blade Cutting for Granite

Diamond blade cutting is highly effective for precise shaping and trimming of granite slabs in construction and countertop fabrication. The blade's durability and ability to produce smooth edges minimize chipping and surface damage, making it ideal for detailed decorative work. This cutting method is preferred for tasks requiring exact dimensions and refined finishes in granite projects.

Equipment and Tool Requirements

Granite core drilling utilizes diamond-tipped drill bits attached to powerful rotary drills, requiring equipment designed for precision and the ability to penetrate hard stone with minimal cracking. Diamond blade cutting employs large, circular saw blades embedded with industrial-grade diamond segments, demanding machinery capable of sustained high-speed rotation and effective water cooling systems to prevent blade overheating. Both methods necessitate specialized tools optimized for durability and accuracy, with core drilling favoring handheld or portable rigs and blade cutting relying on stationary or track saw setups.

Safety Considerations for Both Methods

Granite core drilling minimizes dust and vibration, reducing respiratory and noise hazards compared to diamond blade cutting, which generates significant silica dust and requires extensive protective measures. Proper use of water cooling systems and personal protective equipment (PPE) like respirators and ear protection is critical in both methods to prevent health risks. Awareness of equipment stability and operator training are essential to avoid accidents and ensure safe handling during granite cutting operations.

Cost Implications: Core Drilling vs Diamond Cutting

Granite core drilling generally incurs higher upfront costs due to the specialized equipment and labor required, making it more suitable for large-diameter holes or structural installations. Diamond blade cutting offers a more cost-effective solution for straight cuts with lower labor intensity and faster processing times. Evaluating project scale and precision requirements is essential to balance the cost implications between core drilling and diamond cutting in granite applications.

Choosing the Right Method for Your Granite Project

Granite core drilling offers precise, clean holes ideal for installations like plumbing and electrical conduits, while diamond blade cutting excels in making straight, smooth cuts for countertops and slabs. Selecting the right method depends on the project's requirements: core drilling minimizes material waste and structural damage when creating holes, whereas diamond blade cutting provides efficiency and accuracy for larger, flat surface modifications. Prioritize the method that aligns with your granite project's design and functional needs to ensure optimal results and material integrity.

Granite Core Drilling vs Diamond Blade Cutting Infographic

materialdif.com

materialdif.com