Resin-bonded granite combines crushed granite particles with a resin binder to create a durable, uniform surface, offering enhanced flexibility and resistance to staining compared to natural granite. Natural granite, quarried directly from the earth, provides unique, mineral-rich patterns and superior hardness but requires sealing to maintain its appearance. Choosing between resin-bonded and natural granite depends on the desired balance of aesthetic variety, maintenance, and performance in construction or design projects.

Table of Comparison

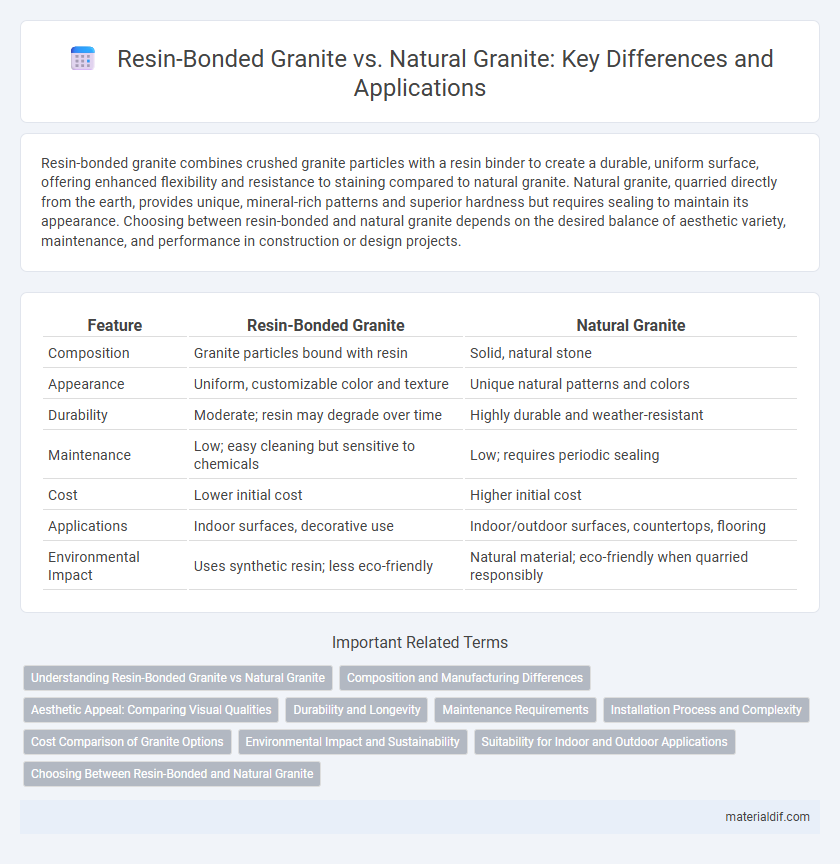

| Feature | Resin-Bonded Granite | Natural Granite |

|---|---|---|

| Composition | Granite particles bound with resin | Solid, natural stone |

| Appearance | Uniform, customizable color and texture | Unique natural patterns and colors |

| Durability | Moderate; resin may degrade over time | Highly durable and weather-resistant |

| Maintenance | Low; easy cleaning but sensitive to chemicals | Low; requires periodic sealing |

| Cost | Lower initial cost | Higher initial cost |

| Applications | Indoor surfaces, decorative use | Indoor/outdoor surfaces, countertops, flooring |

| Environmental Impact | Uses synthetic resin; less eco-friendly | Natural material; eco-friendly when quarried responsibly |

Understanding Resin-Bonded Granite vs Natural Granite

Resin-bonded granite combines crushed granite particles with a durable resin adhesive, offering enhanced flexibility and resistance to chipping compared to natural granite, which is quarried as solid slabs of igneous rock composed primarily of quartz and feldspar. Natural granite boasts superior heat resistance, scratch durability, and a unique natural grain pattern, making it highly prized for countertops and flooring. Resin-bonded granite serves as a cost-effective alternative with easier installation and customizable aesthetics but typically lacks the longevity and natural variation inherent to solid granite slabs.

Composition and Manufacturing Differences

Resin-bonded granite consists of natural granite aggregates bound together with a synthetic resin, creating a composite material with enhanced durability and flexibility compared to solid natural granite. Natural granite is an igneous rock composed mainly of quartz, feldspar, and mica, formed through slow crystallization of magma, resulting in a dense and highly durable stone. The manufacturing process of resin-bonded granite involves mixing granite chips with resin and curing under controlled conditions, while natural granite is quarried, cut, and polished without additional binders.

Aesthetic Appeal: Comparing Visual Qualities

Resin-bonded granite offers a uniform and polished finish with vibrant color consistency, enhancing its sleek and modern aesthetic appeal. Natural granite displays unique, irregular patterns and textures that provide an authentic, earthy look highly valued for traditional and rustic designs. The choice between resin-bonded and natural granite depends on whether a consistent or naturally varied visual quality is preferred for a specific architectural or interior design project.

Durability and Longevity

Resin-bonded granite combines natural granite aggregates with a resin binder, offering enhanced resistance to cracking and chipping compared to natural granite slabs. Natural granite, composed of solid stone, provides superior longevity and can withstand extreme weather conditions but may require regular sealing to maintain its durability. Resin-bonded granite surfaces typically last 10-15 years with minimal maintenance, while natural granite can last several decades, making it a more durable option for high-traffic or outdoor applications.

Maintenance Requirements

Resin-bonded granite requires regular cleaning and occasional resealing to maintain its glossy finish and prevent resin degradation, making it less durable under heavy wear compared to natural granite. Natural granite is highly resistant to stains, scratches, and heat, requiring only periodic sealing and routine cleaning to preserve its natural appearance over time. Choosing natural granite reduces long-term maintenance efforts and costs due to its superior durability and weather resistance.

Installation Process and Complexity

Resin-bonded granite requires a more intricate installation process involving adhesive application and curing time, demanding precision to ensure a durable bond between the granite and substrate. Natural granite installation typically involves mechanical fastening or mortar setting, which can be less complex but requires careful leveling and sealing to prevent damage. The choice between resin-bonded and natural granite impacts labor intensity and time, with resin-bonded options often favored for ease of shaping and reduced weight.

Cost Comparison of Granite Options

Resin-bonded granite typically costs less than natural granite due to lower material and manufacturing expenses, making it a budget-friendly alternative for countertops and flooring. Natural granite, while more expensive, offers superior durability and unique, intricate patterns that increase its long-term value. Consumers seeking cost-effective granite options often choose resin-bonded granite for its aesthetic appeal and affordability, whereas natural granite is preferred for high-end projects requiring enhanced strength and longevity.

Environmental Impact and Sustainability

Resin-bonded granite uses synthetic adhesives that may release volatile organic compounds (VOCs) during production and disposal, impacting air quality and soil health. Natural granite, being a 100% natural stone, offers higher sustainability with minimal processing and longer lifespan, reducing waste and energy consumption. Quarrying practices for natural granite vary in environmental impact, but responsible sourcing can mitigate habitat disruption and carbon footprint.

Suitability for Indoor and Outdoor Applications

Resin-bonded granite offers enhanced flexibility and resistance to staining, making it ideal for indoor applications such as countertops and flooring where aesthetic appeal and easy maintenance are prioritized. Natural granite, known for its durability and weather resistance, is better suited for outdoor environments like patios and facades, enduring harsh weather conditions without significant wear. Both materials provide excellent strength, but the choice depends on environmental exposure and maintenance preferences.

Choosing Between Resin-Bonded and Natural Granite

Choosing between resin-bonded granite and natural granite depends on durability requirements and aesthetic preferences. Resin-bonded granite offers enhanced resistance to stains and chemicals due to its polymer binding, while natural granite provides superior heat resistance and unique natural patterns. Consider maintenance levels and application environment to select the most suitable option for countertops, flooring, or outdoor installations.

Resin-Bonded Granite vs Natural Granite Infographic

materialdif.com

materialdif.com