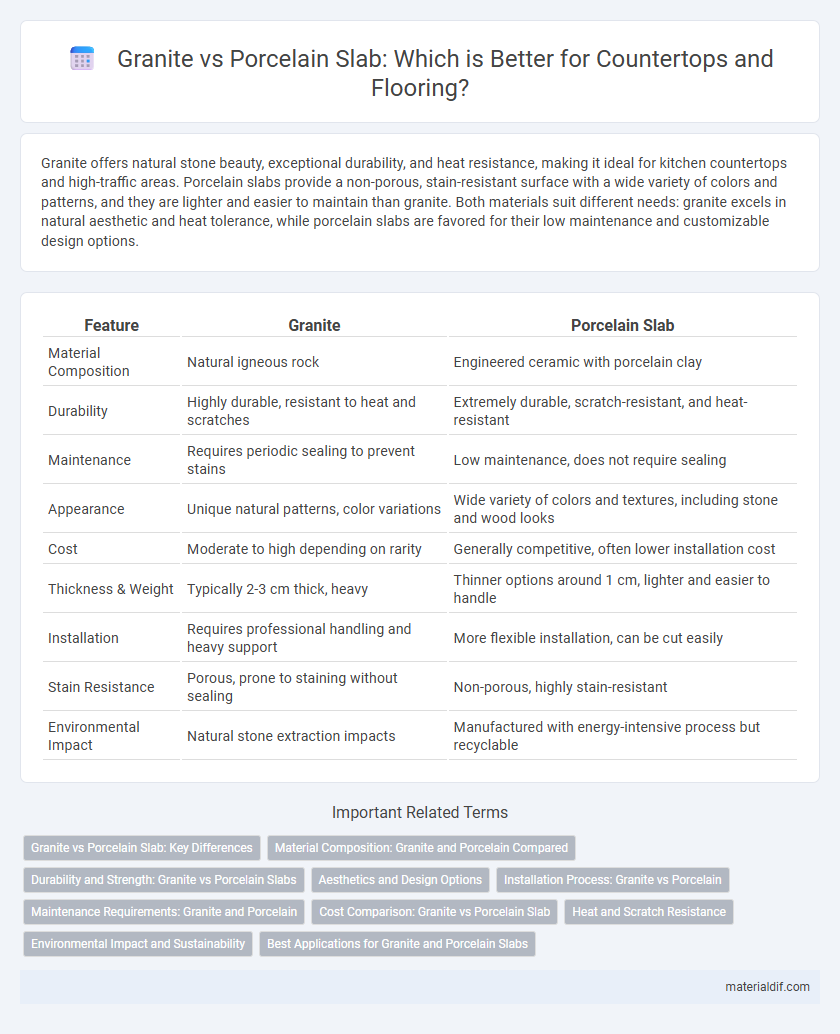

Granite offers natural stone beauty, exceptional durability, and heat resistance, making it ideal for kitchen countertops and high-traffic areas. Porcelain slabs provide a non-porous, stain-resistant surface with a wide variety of colors and patterns, and they are lighter and easier to maintain than granite. Both materials suit different needs: granite excels in natural aesthetic and heat tolerance, while porcelain slabs are favored for their low maintenance and customizable design options.

Table of Comparison

| Feature | Granite | Porcelain Slab |

|---|---|---|

| Material Composition | Natural igneous rock | Engineered ceramic with porcelain clay |

| Durability | Highly durable, resistant to heat and scratches | Extremely durable, scratch-resistant, and heat-resistant |

| Maintenance | Requires periodic sealing to prevent stains | Low maintenance, does not require sealing |

| Appearance | Unique natural patterns, color variations | Wide variety of colors and textures, including stone and wood looks |

| Cost | Moderate to high depending on rarity | Generally competitive, often lower installation cost |

| Thickness & Weight | Typically 2-3 cm thick, heavy | Thinner options around 1 cm, lighter and easier to handle |

| Installation | Requires professional handling and heavy support | More flexible installation, can be cut easily |

| Stain Resistance | Porous, prone to staining without sealing | Non-porous, highly stain-resistant |

| Environmental Impact | Natural stone extraction impacts | Manufactured with energy-intensive process but recyclable |

Granite vs Porcelain Slab: Key Differences

Granite and porcelain slabs differ significantly in composition, durability, and maintenance requirements; granite is a natural stone formed from cooled magma, offering unique patterns and high heat resistance, while porcelain slabs are engineered from clay and minerals, providing uniformity and greater stain resistance. Granite slabs are typically thicker and heavier, requiring professional installation, whereas porcelain slabs are thinner, lighter, and can mimic natural materials with advanced printing technology. Cost variations depend on factors such as slab size, origin, and finishing techniques, with porcelain often being more affordable and easier to maintain over time.

Material Composition: Granite and Porcelain Compared

Granite is a natural igneous rock composed primarily of quartz, feldspar, and mica, known for its durability and unique, natural patterns formed through geological processes. Porcelain slabs are engineered products made from finely ground natural clays, minerals, and pigments, fired at high temperatures to achieve a highly dense and non-porous surface. The mineral composition and manufacturing processes result in granite offering natural variability and porosity, while porcelain slabs provide a more uniform, stain-resistant, and low-maintenance surface.

Durability and Strength: Granite vs Porcelain Slabs

Granite offers exceptional durability with natural resistance to scratches, heat, and impact, making it ideal for high-traffic areas. Porcelain slabs provide superior strength due to their dense composition and are highly resistant to staining, chipping, and UV damage. Both materials maintain longevity, but porcelain's enhanced toughness and minimal porosity give it an edge in environments prone to heavy use and exposure.

Aesthetics and Design Options

Granite offers a natural, unique pattern with rich color variations formed over millions of years, providing an organic and luxurious appearance unmatched by porcelain slabs. Porcelain slabs excel in uniformity and can mimic various materials, including wood and marble, with customizable color and texture options for versatile design applications. Both materials enhance aesthetics differently: granite's natural elegance versus porcelain's adaptability for modern, consistent design schemes.

Installation Process: Granite vs Porcelain

Granite installation involves cutting, shaping, and securing heavy natural stone slabs, often requiring professional expertise and specialized tools like diamond blades and cranes for precise placement. Porcelain slab installation is generally lighter and thinner, allowing for easier handling and quicker cutting with standard tile saws, while porcelain's resistance to scratching and staining reduces the need for sealing. Both materials require proper substrate preparation and adhesive application, but granite demands more labor-intensive anchoring and sealing compared to the streamlined installation process of porcelain slabs.

Maintenance Requirements: Granite and Porcelain

Granite requires periodic sealing to prevent staining and maintain its durability, while porcelain slabs are highly resistant to stains and do not need sealing. Both materials are easy to clean with mild detergent and water, but porcelain's non-porous surface makes it more resistant to bacteria and mold buildup. Granite may require occasional polishing to preserve its shine, contrasting with porcelain's inherently smooth and consistent finish.

Cost Comparison: Granite vs Porcelain Slab

Granite slabs typically cost between $40 and $100 per square foot, influenced by factors like rarity and origin, while porcelain slabs range from $50 to $150 per square foot due to advanced manufacturing processes and design versatility. Installation expenses for granite average around $35 to $45 per hour, whereas porcelain installation may require specialized labor, increasing costs to $45 to $60 per hour. Overall, granite offers a cost-effective option for natural stone enthusiasts, whereas porcelain slabs present a higher upfront investment balanced by durability and design options.

Heat and Scratch Resistance

Granite exhibits superior heat resistance withstanding temperatures up to 1,200degF without damage, making it ideal for kitchen countertops near hot pots and pans. Porcelain slabs also offer excellent scratch resistance due to their hardness rating of 7 on the Mohs scale, but granite's natural mineral composition provides enhanced durability against abrasion. Both materials resist heat and scratches, yet granite's thermal stability and tougher surface make it a preferred choice for high-performance environments.

Environmental Impact and Sustainability

Granite is a natural stone quarried directly from the earth, requiring significant energy for extraction and transportation, which contributes to its environmental footprint. Porcelain slabs are manufactured using refined clay and minerals, often incorporating recycled materials, making them more sustainable with lower carbon emissions in production. Both materials offer durability, but porcelain's lower resource extraction and recyclability give it an environmental advantage over granite in sustainable building projects.

Best Applications for Granite and Porcelain Slabs

Granite slabs excel in kitchen countertops, bathroom vanities, and outdoor applications due to their durability, natural beauty, and heat resistance. Porcelain slabs are ideal for wall cladding, flooring, and commercial surfaces because of their low porosity, stain resistance, and lightweight composition. Choosing between granite and porcelain depends on the specific use case, balancing aesthetic preferences with functional requirements.

Granite vs Porcelain Slab Infographic

materialdif.com

materialdif.com