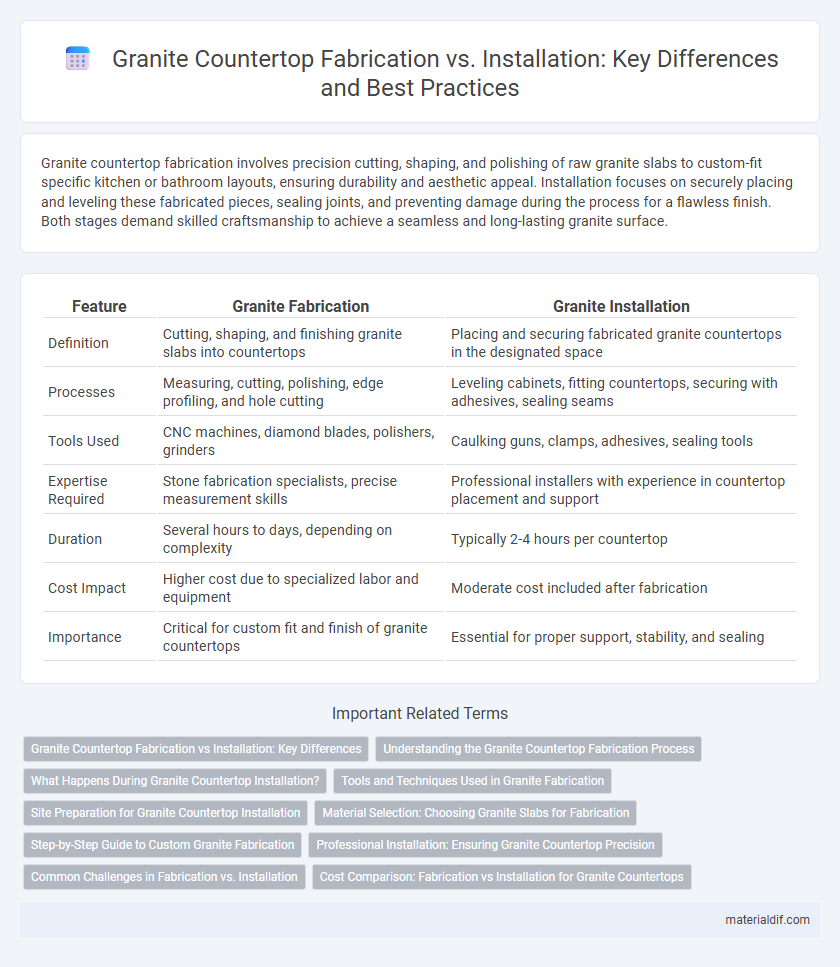

Granite countertop fabrication involves precision cutting, shaping, and polishing of raw granite slabs to custom-fit specific kitchen or bathroom layouts, ensuring durability and aesthetic appeal. Installation focuses on securely placing and leveling these fabricated pieces, sealing joints, and preventing damage during the process for a flawless finish. Both stages demand skilled craftsmanship to achieve a seamless and long-lasting granite surface.

Table of Comparison

| Feature | Granite Fabrication | Granite Installation |

|---|---|---|

| Definition | Cutting, shaping, and finishing granite slabs into countertops | Placing and securing fabricated granite countertops in the designated space |

| Processes | Measuring, cutting, polishing, edge profiling, and hole cutting | Leveling cabinets, fitting countertops, securing with adhesives, sealing seams |

| Tools Used | CNC machines, diamond blades, polishers, grinders | Caulking guns, clamps, adhesives, sealing tools |

| Expertise Required | Stone fabrication specialists, precise measurement skills | Professional installers with experience in countertop placement and support |

| Duration | Several hours to days, depending on complexity | Typically 2-4 hours per countertop |

| Cost Impact | Higher cost due to specialized labor and equipment | Moderate cost included after fabrication |

| Importance | Critical for custom fit and finish of granite countertops | Essential for proper support, stability, and sealing |

Granite Countertop Fabrication vs Installation: Key Differences

Granite countertop fabrication involves cutting, shaping, polishing, and customizing raw granite slabs to fit specific kitchen or bathroom dimensions, utilizing specialized machinery and skilled craftsmanship. Installation focuses on transporting the fabricated granite pieces to the site, ensuring precise alignment, secure anchoring on cabinets, and seamless joins with adhesives and sealants. Both processes require expertise, but fabrication emphasizes material preparation while installation prioritizes site-specific fitting and finishing.

Understanding the Granite Countertop Fabrication Process

Granite countertop fabrication involves precise cutting, shaping, and polishing of raw granite slabs using advanced CNC machinery and skilled craftsmanship to ensure custom fit and aesthetic appeal. This process includes edge profiling, template creation, and surface finishing to match design specifications before installation. Understanding fabrication highlights the importance of accuracy and durability, which directly impacts the final installation quality of granite countertops.

What Happens During Granite Countertop Installation?

Granite countertop installation involves precise placement and secure attachment of the fabricated granite slabs onto the cabinetry, ensuring perfect alignment and level surfaces. Installers use heavy-duty adhesives and anchors to firmly bond the granite to the cabinets, while carefully sealing seams with color-matched epoxy to create a seamless appearance. Final steps include thorough cleaning, polishing the surface to enhance the natural stone's shine, and installing edge finishes to complete the countertop's durability and aesthetic appeal.

Tools and Techniques Used in Granite Fabrication

Granite countertop fabrication involves precise cutting, shaping, and polishing using advanced tools such as CNC routers, bridge saws, and diamond grinders to achieve exact dimensions and smooth finishes. Skilled technicians employ techniques like template creation, edge profiling, and honing to customize slabs according to design specifications, ensuring durability and aesthetic appeal. Installation, by contrast, focuses on securing fabricated slabs with adhesives and supports but does not require the specialized fabrication equipment or detailed finishing processes.

Site Preparation for Granite Countertop Installation

Site preparation for granite countertop installation involves precise measurement, leveling, and ensuring the substrate is clean, dry, and structurally sound before placing the countertop. Proper site preparation minimizes issues like uneven surfaces and ensures seamless granite alignment during installation. Fabrication focuses on cutting, shaping, and polishing granite slabs to exact specifications, while installation requires meticulous site readiness to guarantee a secure and lasting countertop fit.

Material Selection: Choosing Granite Slabs for Fabrication

Granite countertop fabrication begins with selecting high-quality granite slabs known for their durability, unique veining, and rich color variations, ensuring a precise fit and aesthetic appeal. Fabricators assess slab thickness, finish options, and structural integrity to optimize cutting and polishing processes tailored to specific kitchen dimensions and design preferences. Proper material selection directly influences the final countertop's strength, longevity, and overall visual impact, distinguishing fabrication from the installation phase where precision fitting and securing occur.

Step-by-Step Guide to Custom Granite Fabrication

Granite countertop fabrication involves precise measurement, template creation, slab selection, cutting, edging, polishing, and quality inspection to ensure custom fit and finish. Skilled fabricators use advanced tools like CNC routers and water jet cutters to shape and refine the granite according to design specifications. Installation follows fabrication and includes site preparation, countertop setting, leveling, securing, sealing, and final cleanup to complete the kitchen or bathroom renovation.

Professional Installation: Ensuring Granite Countertop Precision

Granite countertop fabrication involves cutting, shaping, and polishing slabs to precise dimensions tailored to the kitchen layout, requiring advanced tools and skilled craftsmanship. Professional installation ensures these meticulously crafted granite pieces fit seamlessly, aligning edges and securing the countertop for durability and aesthetic appeal. Precision in both fabrication and installation is critical to prevent cracks, uneven surfaces, and long-term damage, maintaining the granite's natural beauty and strength.

Common Challenges in Fabrication vs. Installation

Granite countertop fabrication involves precision cutting, edge shaping, and polishing, often facing challenges such as minimizing waste and avoiding cracks during intricate cuts. Installation challenges include ensuring seamless alignment, accurate fitting in irregular spaces, and securing the heavy stone without damaging cabinetry. Both stages demand skilled craftsmanship to manage granite's natural variations and prevent costly errors.

Cost Comparison: Fabrication vs Installation for Granite Countertops

Granite countertop fabrication typically ranges from $40 to $100 per square foot, driven by the complexity of cutting, shaping, and finishing the stone to precise specifications. Installation costs generally fall between $35 and $85 per square foot, influenced by factors such as countertop weight, site accessibility, and existing cabinet conditions. Comparing both, fabrication tends to be more expensive due to skilled labor and specialized equipment, while installation costs can vary widely based on geographic location and the need for additional support structures.

Granite countertop fabrication vs Granite countertop installation Infographic

materialdif.com

materialdif.com