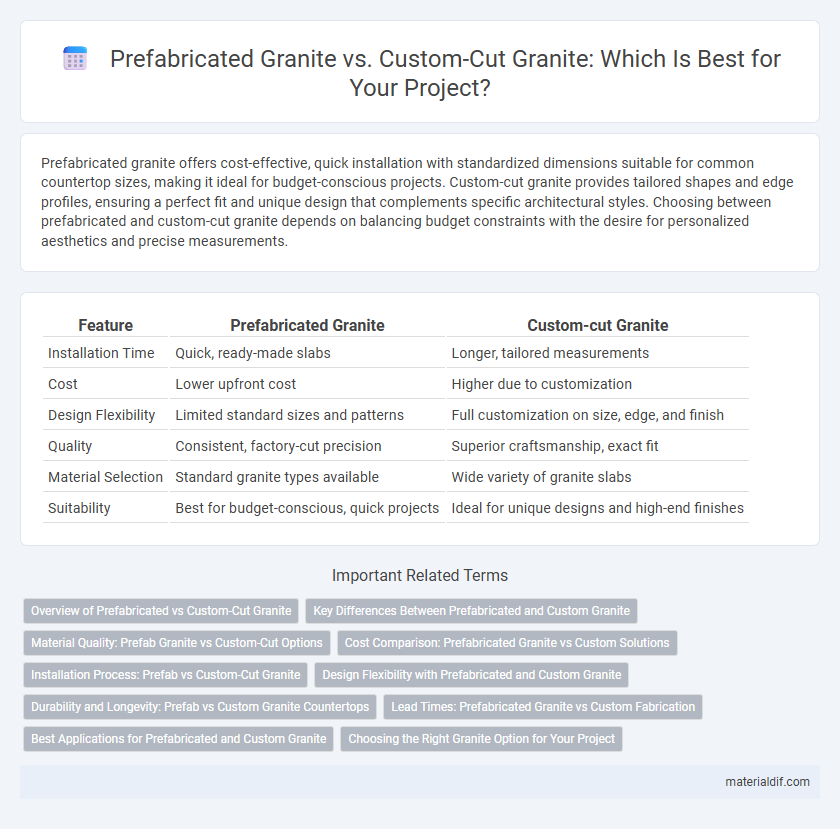

Prefabricated granite offers cost-effective, quick installation with standardized dimensions suitable for common countertop sizes, making it ideal for budget-conscious projects. Custom-cut granite provides tailored shapes and edge profiles, ensuring a perfect fit and unique design that complements specific architectural styles. Choosing between prefabricated and custom-cut granite depends on balancing budget constraints with the desire for personalized aesthetics and precise measurements.

Table of Comparison

| Feature | Prefabricated Granite | Custom-cut Granite |

|---|---|---|

| Installation Time | Quick, ready-made slabs | Longer, tailored measurements |

| Cost | Lower upfront cost | Higher due to customization |

| Design Flexibility | Limited standard sizes and patterns | Full customization on size, edge, and finish |

| Quality | Consistent, factory-cut precision | Superior craftsmanship, exact fit |

| Material Selection | Standard granite types available | Wide variety of granite slabs |

| Suitability | Best for budget-conscious, quick projects | Ideal for unique designs and high-end finishes |

Overview of Prefabricated vs Custom-Cut Granite

Prefabricated granite offers standardized dimensions and consistent quality, making it a cost-effective choice for common countertop sizes and simple design projects. Custom-cut granite provides tailored measurements and unique edge profiles, ideal for complex layouts and personalized aesthetics. Both options use durable, natural stone, but selection depends on project complexity, budget, and desired customization level.

Key Differences Between Prefabricated and Custom Granite

Prefabricated granite offers standardized dimensions and limited design options, making it cost-effective and quickly available for common countertop sizes. Custom-cut granite provides tailored measurements and unique edge profiles that perfectly fit irregular spaces and specific aesthetic preferences, ensuring a personalized finish. The key differences lie in flexibility, price, and installation time, with prefabricated being budget-friendly and faster, while custom granite emphasizes precision and customization.

Material Quality: Prefab Granite vs Custom-Cut Options

Prefabricated granite slabs are produced in controlled factory environments ensuring consistent material quality with standardized thickness and finish. Custom-cut granite allows selection of premium, unique stones often sourced directly from quarries, offering higher-grade material and bespoke surface treatments. While prefab granite provides uniform durability and cost-efficiency, custom-cut granite delivers superior material quality tailored to specific aesthetic and functional requirements.

Cost Comparison: Prefabricated Granite vs Custom Solutions

Prefabricated granite offers a cost-effective solution due to mass production and standard sizing, often priced significantly lower than custom-cut granite. Custom-cut granite involves higher expenses linked to tailored dimensions, unique edge treatments, and personalized installation processes. For budget-conscious projects, prefabricated options reduce upfront costs, while custom-cut granite provides value through bespoke designs at a premium price point.

Installation Process: Prefab vs Custom-Cut Granite

Prefabricated granite boasts a streamlined installation process due to its standardized dimensions, allowing for quicker fitting and reduced labor costs compared to custom-cut granite, which requires precise measurement and onsite adjustments. Custom-cut granite offers tailored fits and unique designs, but installation demands skilled fabricators and longer timelines to accommodate specific project requirements. Selecting between prefabricated and custom-cut granite hinges on the balance between installation speed, customization level, and budget considerations.

Design Flexibility with Prefabricated and Custom Granite

Prefabricated granite offers limited design flexibility due to standardized sizes and shapes, making it ideal for quick installations and budget-conscious projects. Custom-cut granite provides extensive design versatility, allowing precise dimensions, unique edge profiles, and intricate patterns to match specific aesthetic and functional requirements. Projects requiring tailored design elements benefit greatly from custom-cut granite's adaptability compared to the constraints of prefabricated options.

Durability and Longevity: Prefab vs Custom Granite Countertops

Prefabricated granite countertops offer consistent durability due to factory-controlled manufacturing processes that minimize defects and ensure uniform thickness, making them highly resistant to chipping and cracking. Custom-cut granite countertops provide superior longevity by allowing precise edge treatments and thickness tailored to usage needs, enhancing strength in high-traffic kitchen areas. Both options feature natural stone hardness and heat resistance, but custom granite can be optimized for enhanced durability in specific installations, extending the lifespan of countertops significantly.

Lead Times: Prefabricated Granite vs Custom Fabrication

Prefabricated granite offers significantly shorter lead times, often available within days due to standardized sizes and pre-cut slabs ready for installation. Custom-cut granite requires longer lead times, typically several weeks, as it involves precise measurements, shaping, and finishing tailored to specific project requirements. Choosing prefabricated granite is ideal for quick turnarounds, while custom fabrication suits unique designs necessitating detailed craftsmanship.

Best Applications for Prefabricated and Custom Granite

Prefabricated granite is ideal for standardized projects such as kitchen countertops, bathroom vanities, and commercial installations where quick turnaround and cost efficiency are crucial. Custom-cut granite suits unique design requirements, irregular shapes, and intricate patterns often found in bespoke kitchen layouts, luxury bathrooms, or architectural features. Selecting between prefabricated and custom-cut granite depends on project complexity, budget constraints, and desired aesthetic precision.

Choosing the Right Granite Option for Your Project

Prefabricated granite offers cost-effective, readily available slabs ideal for standard countertop dimensions, while custom-cut granite provides precise tailoring to fit unique project specifications and design preferences. Selecting the right granite option depends on budget, project complexity, and desired aesthetics, with custom-cut granite enabling intricate shapes and edge profiles. Consider factors such as installation time, waste minimization, and long-term durability to ensure the granite choice aligns with both functional requirements and visual goals.

Prefabricated Granite vs Custom-cut Granite Infographic

materialdif.com

materialdif.com