Waterjet cut granite offers precise, clean edges without causing heat damage, preserving the stone's natural integrity and color. CNC cut granite provides high accuracy and consistency through automated carving, ideal for intricate designs and repeatable patterns. Choosing between waterjet and CNC cutting depends on the project's complexity, finish requirements, and budget considerations.

Table of Comparison

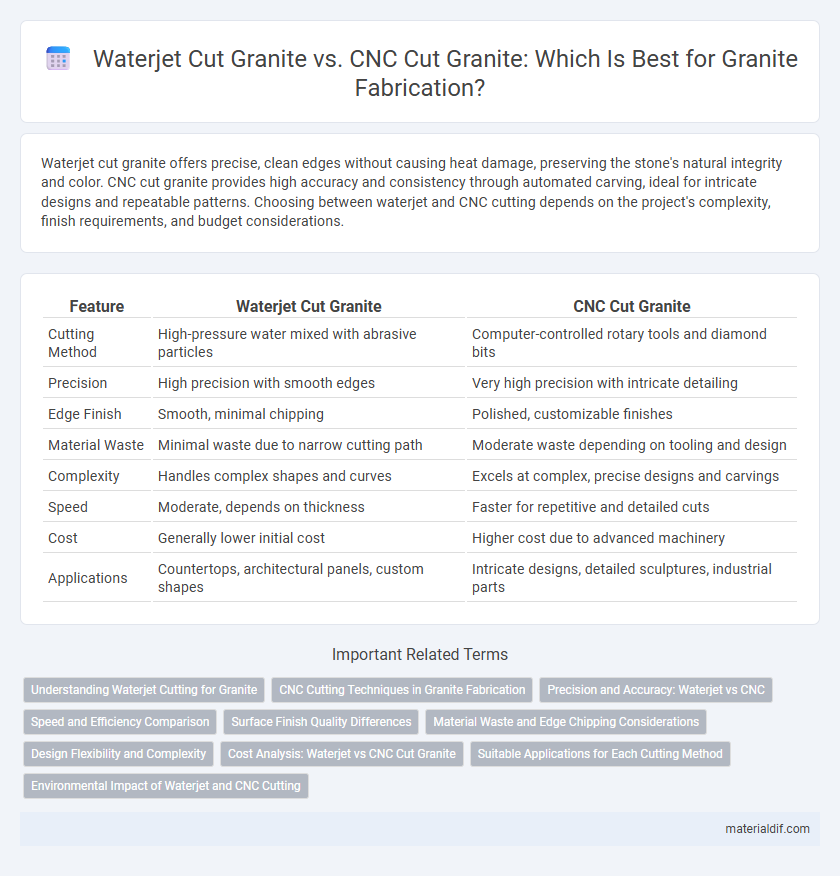

| Feature | Waterjet Cut Granite | CNC Cut Granite |

|---|---|---|

| Cutting Method | High-pressure water mixed with abrasive particles | Computer-controlled rotary tools and diamond bits |

| Precision | High precision with smooth edges | Very high precision with intricate detailing |

| Edge Finish | Smooth, minimal chipping | Polished, customizable finishes |

| Material Waste | Minimal waste due to narrow cutting path | Moderate waste depending on tooling and design |

| Complexity | Handles complex shapes and curves | Excels at complex, precise designs and carvings |

| Speed | Moderate, depends on thickness | Faster for repetitive and detailed cuts |

| Cost | Generally lower initial cost | Higher cost due to advanced machinery |

| Applications | Countertops, architectural panels, custom shapes | Intricate designs, detailed sculptures, industrial parts |

Understanding Waterjet Cutting for Granite

Waterjet cutting for granite utilizes a high-pressure stream of water mixed with abrasive garnet particles, enabling precise and clean cuts without generating heat that could damage the stone. This method is especially effective for intricate designs and maintaining the granite's structural integrity, unlike CNC cutting which involves rotary tools and heat generation. The cold-cutting process of waterjet technology minimizes micro-cracks and preserves the natural beauty of granite slabs, making it ideal for detailed architectural and artistic applications.

CNC Cutting Techniques in Granite Fabrication

CNC cutting techniques in granite fabrication utilize computer-controlled routers and diamond-tipped tools to achieve precise, intricate designs with consistent accuracy and smooth edges. This method outperforms waterjet cutting in speed and repeatability, especially for complex shapes and detailed patterns commonly required in countertops and architectural features. CNC cutting enhances production efficiency by automating the cutting process, reducing material waste, and allowing customization through CAD software integration.

Precision and Accuracy: Waterjet vs CNC

Waterjet cut granite achieves remarkable precision by using a high-pressure stream of water mixed with abrasive particles, allowing intricate and smooth edges with minimal thermal distortion. CNC cut granite employs computer-controlled rotary tools that provide high accuracy through consistent depth control and repeatability, excelling in detailed woodworking and sculpting tasks. While waterjet offers superior edge quality and less material waste, CNC cutting delivers exact dimensional accuracy and faster production rates for complex shapes.

Speed and Efficiency Comparison

Waterjet cut granite offers precise, clean edges with minimal material waste, making it highly efficient for intricate designs. CNC cut granite excels in speed for larger, repetitive cuts due to automated programming and rapid tool movements. Both methods optimize production timelines, but CNC cutting generally provides faster throughput for high-volume granite fabrication projects.

Surface Finish Quality Differences

Waterjet cut granite delivers a smooth, natural surface finish with minimal heat impact, preserving the stone's inherent texture and color variations. CNC cut granite offers precise, consistent edges and intricate detailing but may produce a slightly rougher surface due to mechanical abrasion. The choice between waterjet and CNC cutting largely depends on the desired finish quality and the complexity of the design.

Material Waste and Edge Chipping Considerations

Waterjet cut granite offers minimal material waste due to its precise, narrow cutting kerf, preserving more stone compared to CNC cutting methods. CNC cut granite may experience higher material loss and increased edge chipping risk because of mechanical tool vibrations and heat generated during the cutting process. Choosing waterjet cutting reduces the likelihood of edge chipping, ensuring cleaner, smoother edges ideal for intricate designs and maintaining structural integrity.

Design Flexibility and Complexity

Waterjet cut granite offers superior design flexibility by utilizing high-pressure water mixed with abrasive materials to create intricate, detailed patterns that are difficult to achieve with traditional methods. CNC cut granite relies on computer-controlled routers and diamond-tipped tools, which excel in producing precise, repetitive shapes but are limited in handling extremely complex curves and fine details. For projects requiring elaborate designs and non-standard shapes, waterjet cutting provides enhanced versatility and complexity compared to CNC cutting.

Cost Analysis: Waterjet vs CNC Cut Granite

Waterjet cut granite typically incurs higher operational costs due to the expensive maintenance of high-pressure pumps and abrasive materials, though it offers exceptional precision for intricate designs. CNC cut granite, while generally more cost-efficient, provides faster production speeds with lower wear on tools, making it ideal for large-scale projects with standard patterns. Overall, the choice between waterjet and CNC cutting hinges on balancing budget constraints against the required detail and finish quality.

Suitable Applications for Each Cutting Method

Waterjet cut granite excels in creating intricate shapes and delicate designs, making it ideal for custom countertops, detailed architectural elements, and artistic stonework where precision is critical without heat distortion. CNC cut granite is best suited for projects requiring high-volume production and uniformity, such as large-scale flooring tiles, stair treads, and engineered stone products, due to its speed and consistent repeatability. Selection between waterjet and CNC cutting depends on the balance between design complexity and production efficiency for each granite application.

Environmental Impact of Waterjet and CNC Cutting

Waterjet cut granite uses high-pressure water mixed with abrasive materials, consuming significant amounts of water and generating slurry waste that requires proper disposal to prevent environmental contamination. CNC cut granite relies on carbide tools and lubricants that produce dust and coolant waste, which can impact air and water quality if not managed effectively. Both cutting methods demand energy consumption, but waterjet cutting generally consumes more power due to the high-pressure pumps, influencing their overall environmental footprints.

Waterjet Cut Granite vs CNC Cut Granite Infographic

materialdif.com

materialdif.com