Granite core drilling uses tungsten carbide or diamond-impregnated bits to penetrate the dense rock, offering durability and efficiency for large-scale construction projects. Diamond core drilling specifically employs industrial-grade diamonds, providing superior precision and faster cutting speeds in hard granite formations. This method minimizes micro-cracks and ensures smoother core samples, making it ideal for geological and engineering applications requiring high-quality results.

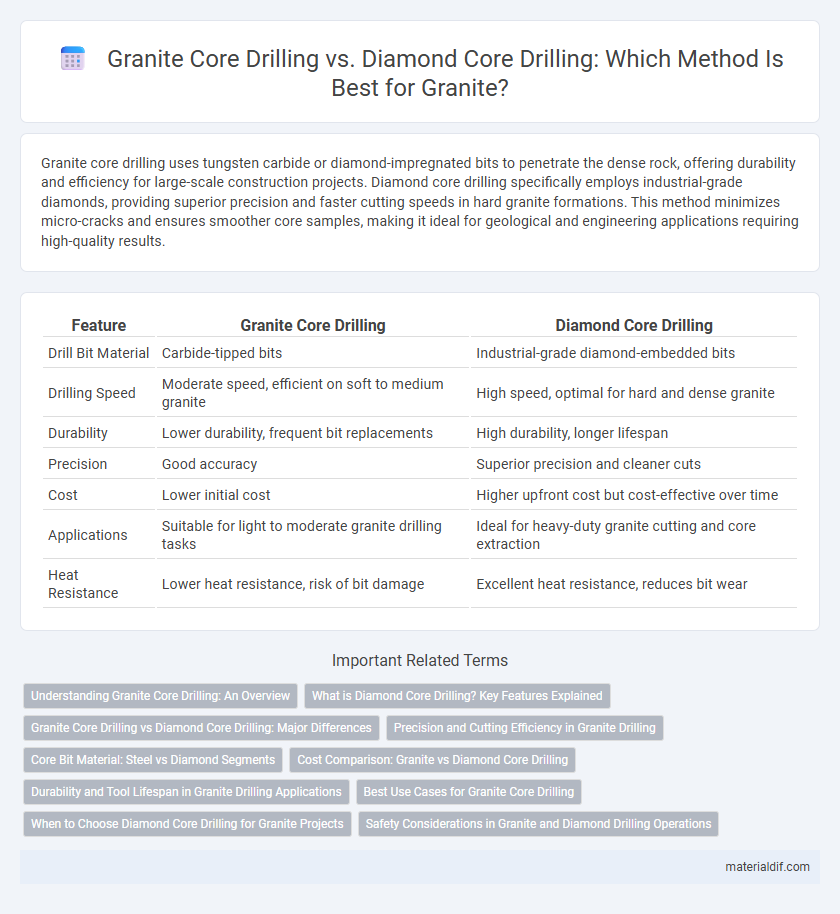

Table of Comparison

| Feature | Granite Core Drilling | Diamond Core Drilling |

|---|---|---|

| Drill Bit Material | Carbide-tipped bits | Industrial-grade diamond-embedded bits |

| Drilling Speed | Moderate speed, efficient on soft to medium granite | High speed, optimal for hard and dense granite |

| Durability | Lower durability, frequent bit replacements | High durability, longer lifespan |

| Precision | Good accuracy | Superior precision and cleaner cuts |

| Cost | Lower initial cost | Higher upfront cost but cost-effective over time |

| Applications | Suitable for light to moderate granite drilling tasks | Ideal for heavy-duty granite cutting and core extraction |

| Heat Resistance | Lower heat resistance, risk of bit damage | Excellent heat resistance, reduces bit wear |

Understanding Granite Core Drilling: An Overview

Granite core drilling involves extracting cylindrical samples from granite rock using specialized drill bits and high-pressure water or drilling fluids to reduce heat and remove debris. This method requires high durability and precision due to granite's hardness and abrasive nature, often necessitating the use of diamond core drilling techniques for enhanced efficiency and longevity. Diamond core drilling employs superabrasive diamond-impregnated drill bits, offering superior cutting power and wear resistance, making it the preferred choice for effective granite core sampling and construction applications.

What is Diamond Core Drilling? Key Features Explained

Diamond core drilling uses a drill bit embedded with industrial-grade diamonds, enabling precise and efficient cutting through hard materials like granite. This method offers superior durability, faster drilling speeds, and cleaner, more accurate core samples compared to traditional core drilling techniques. Essential for construction, mining, and geological applications, diamond core drilling ensures maximum penetration and minimal material wastage.

Granite Core Drilling vs Diamond Core Drilling: Major Differences

Granite core drilling utilizes specialized tungsten carbide-tipped bits designed to penetrate the dense, coarse-grained structure of granite, while diamond core drilling employs industrial-grade diamond-embedded drill bits providing superior hardness and cutting efficiency. The drilling speed in diamond core drilling is significantly faster due to diamond's higher abrasion resistance and heat dispersion capabilities, leading to less bit wear and longer operational life. Granite core drilling is more cost-effective for less frequent or small-scale applications, whereas diamond core drilling is preferred for precision, durability, and large-scale granite extraction projects.

Precision and Cutting Efficiency in Granite Drilling

Granite core drilling using diamond core bits offers superior precision and cutting efficiency due to the hardness and durability of diamond, enabling smoother, faster penetration through tough granite surfaces. Conventional core drilling methods often struggle with accuracy and wear quickly when applied to dense granite, resulting in slower progress and less precise holes. The enhanced cutting efficiency of diamond core drilling reduces drill bit replacement frequency and minimizes granite chipping, ensuring high-quality, precise boreholes essential for structural applications.

Core Bit Material: Steel vs Diamond Segments

Granite core drilling uses steel core bits that rely on the hardness and strength of steel to penetrate the rock, but diamond core drilling employs diamond segments embedded in the bit, providing superior cutting efficiency and durability. Diamond segments are specifically engineered to grind through hard granite with precision, ensuring faster drilling speeds and longer bit life. Steel core bits wear down quickly in granite applications, whereas diamond core bits maintain consistent performance, reducing downtime and operational costs.

Cost Comparison: Granite vs Diamond Core Drilling

Granite core drilling typically incurs lower costs due to the use of less expensive drill bits and simpler equipment, making it more budget-friendly for large-scale stone extraction. Diamond core drilling, while more costly upfront because of the expensive diamond-tipped drill bits and advanced machinery, offers superior precision and durability for hard granite, reducing wear and replacement frequency. When comparing granite versus diamond core drilling, the higher initial investment in diamond core drilling is often offset by increased efficiency and longer tool life, making it a cost-effective choice for intricate or high-volume granite projects.

Durability and Tool Lifespan in Granite Drilling Applications

Granite core drilling using diamond-tipped bits outperforms traditional core drilling tools in durability due to diamond's exceptional hardness, which enables sustained penetration through dense granite without rapid wear. Tool lifespan in diamond core drilling is significantly extended, reducing downtime and operational costs in granite applications by maintaining sharp cutting edges longer under high-stress conditions. This enhanced durability drives efficiency in construction and geological projects, where precise and continuous core extraction from granite is critical.

Best Use Cases for Granite Core Drilling

Granite core drilling excels in heavy-duty applications requiring precision and durability, especially in construction projects involving thick granite slabs or structural foundation work. Its best use cases include creating large-diameter holes for utilities or anchoring systems where standard diamond core drilling may be less efficient or cost-effective. This method offers enhanced stability and faster penetration rates when dealing with extremely hard and abrasive granite materials.

When to Choose Diamond Core Drilling for Granite Projects

Diamond core drilling is the preferred choice for granite projects requiring precise, clean, and smooth holes due to its superior hardness and durability compared to conventional core drills. It excels in penetrating dense, abrasive granite while minimizing cracking and material waste, making it ideal for architectural and structural applications where finish quality is critical. Projects demanding deep hole drilling and high efficiency benefit significantly from diamond core drilling, as it reduces overall drilling time and enhances tool lifespan.

Safety Considerations in Granite and Diamond Drilling Operations

Granite core drilling requires enhanced safety measures due to the material's hardness and potential for generating excessive heat, demanding adequate cooling and dust control to prevent respiratory hazards and equipment damage. Diamond core drilling offers improved operational safety by reducing vibration and minimizing structural impact, though it still necessitates protective gear and proper handling to avoid fractures or tool failure. Both methods must incorporate rigorous risk assessments and compliance with industry safety standards to ensure worker protection during granite drilling projects.

Granite Core Drilling vs Diamond Core Drilling Infographic

materialdif.com

materialdif.com