Sawn granite offers a smooth, polished surface ideal for modern architectural designs, providing a sleek and elegant finish. Split-face granite features a rough, textured appearance created by splitting the stone, adding a natural, rugged aesthetic perfect for rustic or outdoor applications. Choosing between sawn and split-face granite depends on the desired visual impact and the specific use case in construction or landscaping projects.

Table of Comparison

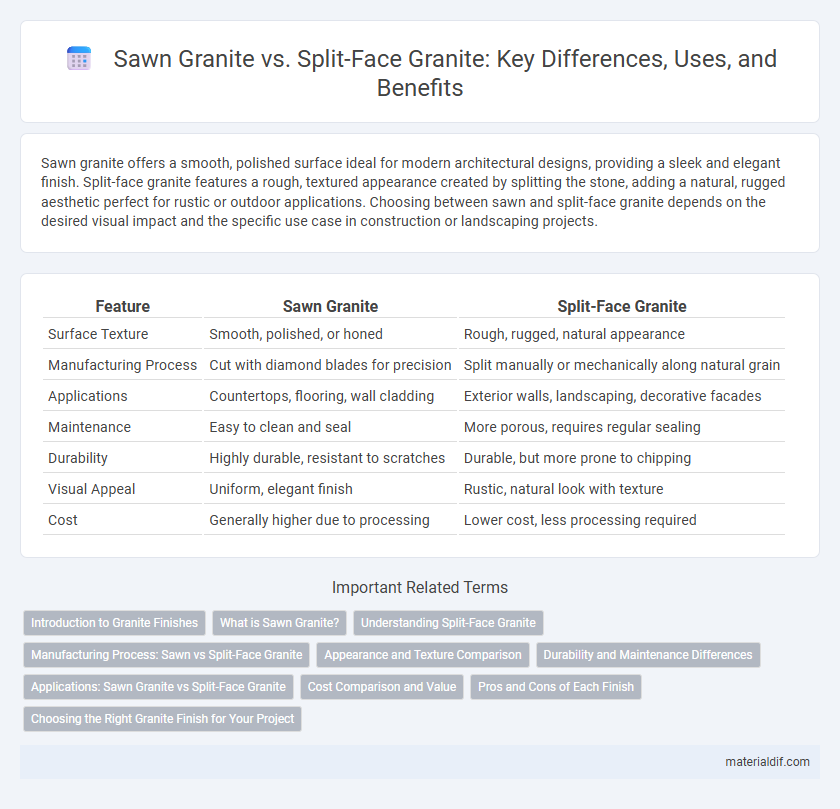

| Feature | Sawn Granite | Split-Face Granite |

|---|---|---|

| Surface Texture | Smooth, polished, or honed | Rough, rugged, natural appearance |

| Manufacturing Process | Cut with diamond blades for precision | Split manually or mechanically along natural grain |

| Applications | Countertops, flooring, wall cladding | Exterior walls, landscaping, decorative facades |

| Maintenance | Easy to clean and seal | More porous, requires regular sealing |

| Durability | Highly durable, resistant to scratches | Durable, but more prone to chipping |

| Visual Appeal | Uniform, elegant finish | Rustic, natural look with texture |

| Cost | Generally higher due to processing | Lower cost, less processing required |

Introduction to Granite Finishes

Sawn granite features a smooth, flat surface achieved through diamond saw cutting, highlighting the stone's natural color and grain with a polished or honed finish ideal for countertops and flooring. Split-face granite, created by mechanical or manual splitting, exhibits a rough, textured surface that enhances the stone's rugged, natural appearance, often used in exterior cladding and accent walls. Both finishes maximize granite's durability and aesthetic appeal, with sawn surfaces providing sleek elegance and split-face textures offering rustic, architectural character.

What is Sawn Granite?

Sawn granite is a type of granite finish obtained by cutting the stone with precise diamond-tipped saw blades, resulting in a smooth, flat surface with sharp edges. This finish enhances the natural color and pattern of the granite, making it ideal for countertops, flooring, and decorative wall cladding. Sawn granite offers durability, a polished appearance, and a refined texture compared to the rougher split-face granite.

Understanding Split-Face Granite

Split-face granite features a textured, rugged surface created by mechanically splitting the stone along its natural grain, enhancing slip resistance and providing a rustic aesthetic ideal for exterior walls and landscaping. Unlike sawn granite, which has a smooth, polished finish achieved through precise cutting and grinding, split-face granite retains the stone's natural character and irregularities. This finish highlights the granite's inherent durability, making it suitable for high-traffic outdoor applications and decorative facades where natural beauty and weather resistance are essential.

Manufacturing Process: Sawn vs Split-Face Granite

Sawn granite is produced by cutting the stone with a diamond-tipped saw, resulting in a smooth, flat surface ideal for precise architectural applications. Split-face granite, on the other hand, is created by mechanically splitting the rock along its natural grain, producing a rough, textured surface that enhances slip resistance and aesthetic depth. The manufacturing process for sawn granite demands precision cutting technology, while split-face granite relies on controlled fracturing techniques to achieve its distinctive rugged appearance.

Appearance and Texture Comparison

Sawn granite features a smooth, polished surface with clean, precise edges, enhancing its sleek and refined appearance ideal for countertops and flooring. Split-face granite exhibits a rough, natural texture with irregular, jagged edges, providing a rustic, rugged aesthetic perfect for exterior walls and landscaping. The contrasting textures of sawn and split-face granite serve distinct design purposes, with sawn granite emphasizing elegance and split-face granite highlighting natural ruggedness.

Durability and Maintenance Differences

Sawn granite features a smooth, polished surface that is highly resistant to scratches and stains, making it easier to maintain with regular cleaning and occasional sealing. Split-face granite has a rough, textured surface that can trap dirt and grime, requiring more frequent cleaning and careful maintenance to preserve its natural appearance. Both types offer exceptional durability typical of granite, but the maintenance effort varies significantly due to their surface treatments.

Applications: Sawn Granite vs Split-Face Granite

Sawn granite offers a smooth, polished surface ideal for countertops, flooring, and architectural facades requiring precise, clean lines. Split-face granite provides a rough, textured appearance suited for exterior walls, landscaping, and decorative veneers that emphasize natural, rugged aesthetics. Applications choosing between these finishes often consider both functional durability and desired visual impact in residential or commercial projects.

Cost Comparison and Value

Sawn granite undergoes precise cutting, resulting in a smooth, polished surface that commands a higher price due to labor-intensive processing and premium aesthetic appeal, making it a valuable investment for upscale projects. Split-face granite features a rough, natural texture achieved by manual splitting, offering a cost-effective alternative while maintaining durability and unique visual interest suitable for rustic or outdoor applications. The choice between sawn and split-face granite hinges on budget constraints and design goals, with sawn granite providing greater asset value and split-face granite delivering affordability without compromising on longevity.

Pros and Cons of Each Finish

Sawn granite offers a smooth, polished surface that enhances the stone's natural color and pattern, making it ideal for countertops and decorative applications, but it can be slippery when wet and may show scratches more easily. Split-face granite provides a rough, textured finish that offers superior slip resistance and a rustic aesthetic, suitable for exterior walls and landscaping; however, it can be harder to clean and may not complement indoor environments as seamlessly. Each finish's durability remains typical of granite, but the choice depends on the desired appearance and functional requirements of the project.

Choosing the Right Granite Finish for Your Project

Sawn granite offers a smooth, precise surface ideal for modern architectural designs, enhancing durability and ease of cleaning. Split-face granite provides a natural, rugged texture, perfect for creating rustic or decorative accents that emphasize organic stone patterns. Selecting the right finish depends on project aesthetic goals, maintenance requirements, and the desired tactile experience.

Sawn Granite vs Split-Face Granite Infographic

materialdif.com

materialdif.com