Granite surface plates offer superior resistance to corrosion and thermal stability compared to cast iron surface plates, ensuring precise and consistent measurements over time. Cast iron surface plates are more susceptible to rust and require regular maintenance, whereas granite's non-porous nature minimizes wear and tear. The inherent hardness and vibration damping properties of granite make it a preferred choice for high-accuracy industrial applications.

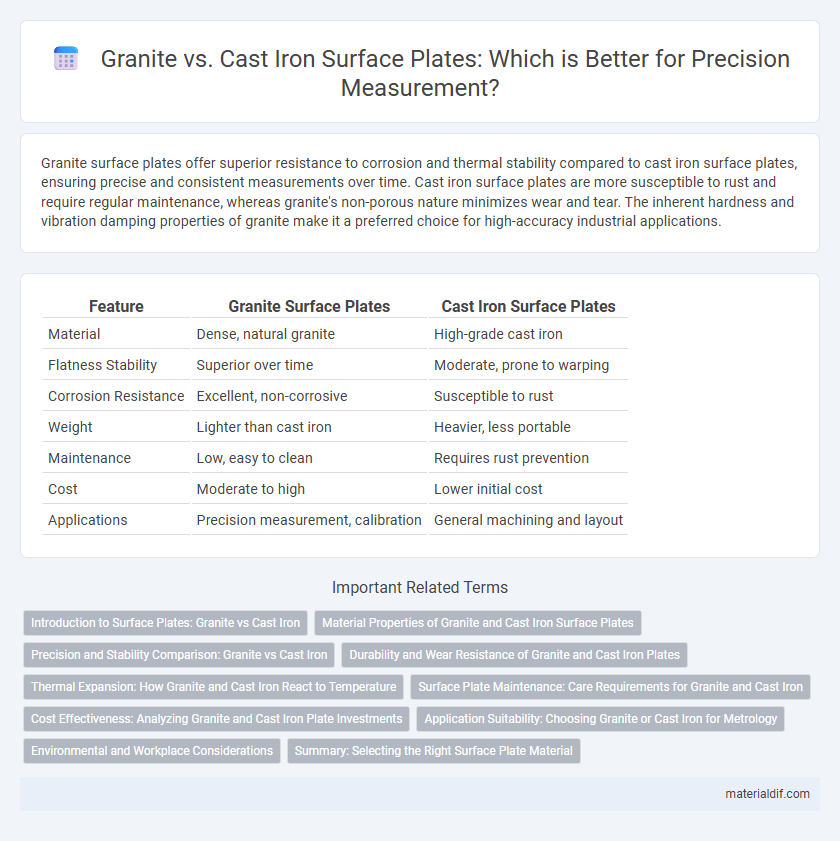

Table of Comparison

| Feature | Granite Surface Plates | Cast Iron Surface Plates |

|---|---|---|

| Material | Dense, natural granite | High-grade cast iron |

| Flatness Stability | Superior over time | Moderate, prone to warping |

| Corrosion Resistance | Excellent, non-corrosive | Susceptible to rust |

| Weight | Lighter than cast iron | Heavier, less portable |

| Maintenance | Low, easy to clean | Requires rust prevention |

| Cost | Moderate to high | Lower initial cost |

| Applications | Precision measurement, calibration | General machining and layout |

Introduction to Surface Plates: Granite vs Cast Iron

Granite surface plates offer superior thermal stability, corrosion resistance, and non-magnetic properties, making them ideal for precision measurement and inspection tasks. Cast iron surface plates provide robust durability and excellent vibration damping but require regular maintenance to prevent rust and corrosion. Selecting between granite and cast iron depends on specific application requirements, environmental conditions, and desired accuracy levels in industrial metrology.

Material Properties of Granite and Cast Iron Surface Plates

Granite surface plates offer superior hardness, wear resistance, and thermal stability compared to cast iron, ensuring precise measurements with minimal deformation over time. Cast iron plates, although durable, are more prone to corrosion and dimensional changes due to temperature fluctuations, impacting their long-term accuracy. The non-porous, vibration-dampening nature of granite makes it the preferred choice for high-precision metrology applications.

Precision and Stability Comparison: Granite vs Cast Iron

Granite surface plates offer superior precision and long-term stability due to their natural hardness and resistance to wear, reducing surface warping and maintaining flatness over time. Cast iron plates provide good durability but are prone to rust and can deform under heavy loads, affecting measurement accuracy. The low thermal expansion coefficient of granite enhances measurement consistency in varying temperatures, making it the preferred choice for high-precision applications.

Durability and Wear Resistance of Granite and Cast Iron Plates

Granite surface plates exhibit superior durability and wear resistance due to their natural hardness and resistance to corrosion, ensuring prolonged flatness and minimal deformation over time. Cast iron surface plates, while robust and highly effective in absorbing vibrations, are prone to rust and require regular maintenance to prevent surface degradation. The inherent stability of granite against thermal expansion and chemical attack makes it the preferred choice for precision measurement environments demanding long-term reliability.

Thermal Expansion: How Granite and Cast Iron React to Temperature

Granite surface plates exhibit low thermal expansion, allowing precise measurements even with fluctuating temperatures, while cast iron surface plates experience higher thermal expansion, potentially leading to dimensional inaccuracies. The coefficient of thermal expansion for granite ranges between 4.5 to 8 x 10^-6 per degC, significantly lower than cast iron's coefficient of approximately 10 to 12 x 10^-6 per degC. This inherent stability in granite enhances metrology applications where temperature variations are unavoidable, ensuring consistent calibration and measurement accuracy.

Surface Plate Maintenance: Care Requirements for Granite and Cast Iron

Granite surface plates require minimal maintenance due to their natural hardness and resistance to corrosion, needing only regular cleaning with a soft cloth and mild detergent to maintain accuracy and flatness. Cast iron surface plates demand more rigorous upkeep, including frequent cleaning to prevent rust and periodic reconditioning such as grinding or lapping to maintain a smooth, flat surface. Proper maintenance of both materials is essential for ensuring precision in measurement and extending the lifespan of the surface plates.

Cost Effectiveness: Analyzing Granite and Cast Iron Plate Investments

Granite surface plates generally offer higher cost effectiveness due to their superior durability, resistance to corrosion, and lower maintenance requirements compared to cast iron plates. Although cast iron surface plates are initially less expensive, they tend to require more frequent calibration and repair, increasing long-term expenses. The investment in granite plates typically results in better value over time, especially in precision measurement applications where stability and accuracy are critical.

Application Suitability: Choosing Granite or Cast Iron for Metrology

Granite surface plates excel in metrology due to their superior hardness, low thermal expansion, and resistance to corrosion, making them ideal for precision measurements in temperature-variable environments. Cast iron surface plates offer excellent durability and vibration damping but are more susceptible to rust and require regular maintenance, which limits their application in humid or corrosive settings. Selecting between granite and cast iron depends on the specific measurement accuracy required, environmental conditions, and maintenance capabilities within the metrology lab.

Environmental and Workplace Considerations

Granite surface plates offer superior resistance to corrosion and require minimal maintenance, making them more environmentally sustainable and reducing chemical use in the workplace compared to cast iron plates. Cast iron surface plates are heavier and prone to rust, necessitating regular lubrication and protective coatings that can introduce hazardous substances into the environment. Choosing granite enhances air quality and worker safety by minimizing exposure to oil-based residues and reducing long-term environmental impact.

Summary: Selecting the Right Surface Plate Material

Granite surface plates offer superior resistance to corrosion, minimal thermal expansion, and excellent stability, making them ideal for precision measurement tasks. Cast iron surface plates provide durability and high load-bearing capacity but require regular maintenance to prevent rust and wear. Choosing the right surface plate material depends on application requirements, environmental conditions, and maintenance capabilities to ensure long-term accuracy and reliability.

Granite Surface Plates vs Cast Iron Surface Plates Infographic

materialdif.com

materialdif.com