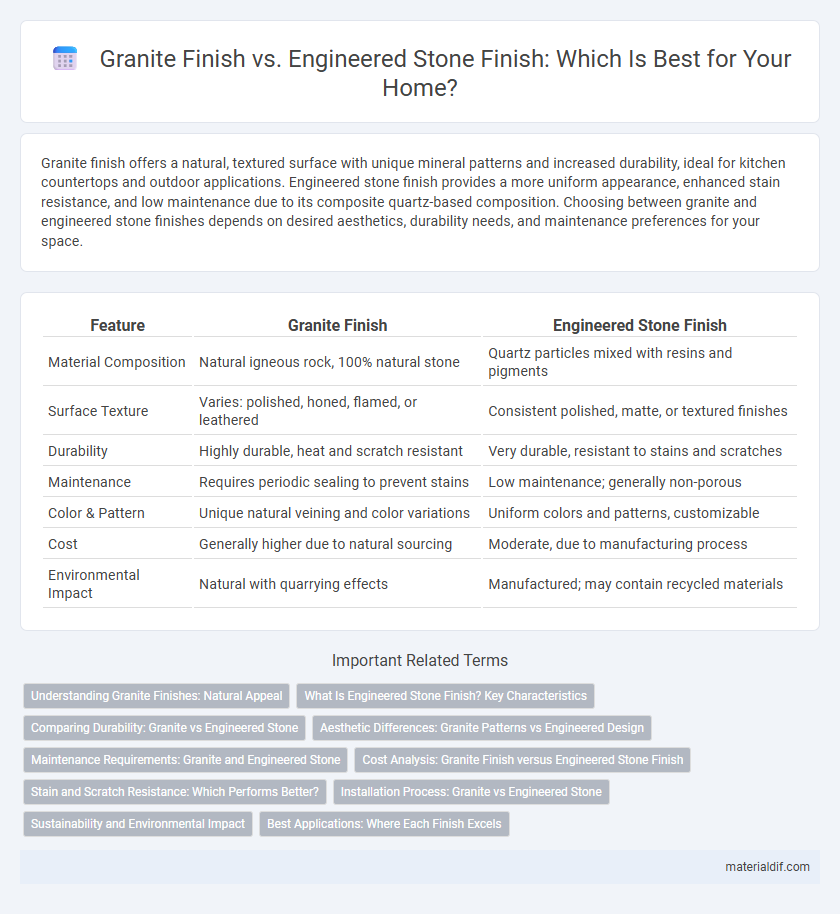

Granite finish offers a natural, textured surface with unique mineral patterns and increased durability, ideal for kitchen countertops and outdoor applications. Engineered stone finish provides a more uniform appearance, enhanced stain resistance, and low maintenance due to its composite quartz-based composition. Choosing between granite and engineered stone finishes depends on desired aesthetics, durability needs, and maintenance preferences for your space.

Table of Comparison

| Feature | Granite Finish | Engineered Stone Finish |

|---|---|---|

| Material Composition | Natural igneous rock, 100% natural stone | Quartz particles mixed with resins and pigments |

| Surface Texture | Varies: polished, honed, flamed, or leathered | Consistent polished, matte, or textured finishes |

| Durability | Highly durable, heat and scratch resistant | Very durable, resistant to stains and scratches |

| Maintenance | Requires periodic sealing to prevent stains | Low maintenance; generally non-porous |

| Color & Pattern | Unique natural veining and color variations | Uniform colors and patterns, customizable |

| Cost | Generally higher due to natural sourcing | Moderate, due to manufacturing process |

| Environmental Impact | Natural with quarrying effects | Manufactured; may contain recycled materials |

Understanding Granite Finishes: Natural Appeal

Granite finishes enhance the stone's natural appeal by preserving its unique textures and colors, with options like polished, honed, and flamed surfaces that highlight its inherent beauty. Natural granite finishes showcase the stone's granular composition and organic patterns, offering durability and a timeless aesthetic ideal for countertops and flooring. Engineered stone finishes, by contrast, provide a more uniform appearance but lack the authentic variation and tactile feel characteristic of natural granite.

What Is Engineered Stone Finish? Key Characteristics

Engineered stone finish refers to a composite material made by combining crushed natural quartz with resin and pigments, creating a durable and non-porous surface. This finish offers high resistance to scratches, stains, and heat, making it ideal for kitchen countertops and high-traffic areas. Engineered stone surfaces provide consistent patterns and colors, unlike the natural variances found in granite finishes.

Comparing Durability: Granite vs Engineered Stone

Granite offers superior durability due to its natural hardness and resistance to heat, scratches, and stains, making it ideal for high-traffic kitchen surfaces. Engineered stone, composed of crushed quartz mixed with resin, provides excellent durability but can be more prone to damage from extreme heat and certain chemicals. Both materials require regular sealing, though granite's natural composition generally translates to greater long-term resilience in demanding environments.

Aesthetic Differences: Granite Patterns vs Engineered Design

Granite finish showcases naturally occurring patterns with unique veining and color variations formed over millions of years, offering a distinct, organic aesthetic. Engineered stone finish presents a more uniform and consistent design, allowing for customized colors and patterns that mimic or amplify natural stone appearances. The aesthetic difference lies in granite's unpredictable, earthy elegance versus engineered stone's versatility and precision in design.

Maintenance Requirements: Granite and Engineered Stone

Granite surfaces require periodic sealing to prevent staining and maintain their natural appearance, making regular cleaning with mild detergent essential for longevity. Engineered stone, composed primarily of quartz and resin, offers a non-porous finish that resists staining and generally demands less frequent sealing and simpler maintenance routines. Both materials benefit from prompt spill cleanup, but engineered stone's durability and low porosity reduce the overall effort needed to keep the surface looking pristine.

Cost Analysis: Granite Finish versus Engineered Stone Finish

Granite finish typically costs between $40 to $100 per square foot, driven by natural stone's extraction and processing expenses, while engineered stone finish ranges from $50 to $120 per square foot due to resin and manufacturing costs. Maintenance and durability influence overall value, with granite offering higher heat resistance and engineered stone providing stain resistance at a lower price point. Evaluating lifecycle costs highlights granite's long-term durability against engineered stone's upfront affordability and ease of upkeep.

Stain and Scratch Resistance: Which Performs Better?

Granite finish offers superior natural stain and scratch resistance due to its dense, hard composition and minimal porosity, making it highly durable for heavy-use surfaces. Engineered stone finish, typically composed of quartz and resin, provides enhanced stain resistance thanks to its non-porous surface but may be more susceptible to scratches compared to granite. When comparing performance, granite excels in scratch resistance while engineered stone edges out in preventing stains, influencing the choice based on specific usage needs.

Installation Process: Granite vs Engineered Stone

Granite installation requires precise cutting and heavy-duty tools due to its natural density and hardness, often necessitating professional expertise to ensure seamless fitting and secure adhesion. Engineered stone finish, composed of resin and crushed quartz, allows for easier handling and faster installation with standard tools, reducing labor time and minimizing risk of breakage. Both finishes demand careful surface preparation and leveling, but engineered stone typically offers more consistent slab sizes, simplifying the alignment during installation.

Sustainability and Environmental Impact

Granite finish, sourced directly from natural quarries, offers exceptional durability and longevity with minimal processing, reducing its carbon footprint and promoting sustainability. Engineered stone finish, composed of crushed quartz combined with resins and pigments, involves more intensive manufacturing processes that can increase energy consumption and environmental impact. Choosing natural granite supports eco-friendly practices by minimizing synthetic material use and fostering responsible quarrying methods aligned with environmental preservation.

Best Applications: Where Each Finish Excels

Granite finish excels in high-traffic kitchen countertops and outdoor applications due to its natural durability and resistance to heat and scratches. Engineered stone finish offers superior stain resistance and uniform appearance, making it ideal for bathrooms, commercial spaces, and modern interior designs. Both finishes provide longevity, but the choice depends on the required aesthetic and functional demands.

Granite Finish vs Engineered Stone Finish Infographic

materialdif.com

materialdif.com